Welcome to Day Five of Microsoldering School, where we focus on mastering advanced techniques essential for precision repairs. This session is designed to refine your skills and deepen your understanding of intricate microsoldering processes. Participants will engage in hands-on practice, learning to tackle complex repairs with confidence and accuracy. By the end of the day, you will have honed your abilities to handle delicate components, troubleshoot effectively, and apply advanced soldering techniques that are crucial for professional-level repairs. Prepare to elevate your microsoldering expertise to new heights!

Advanced Microsoldering Techniques

As we progress into Day Five of our microsoldering school, the focus shifts to advanced microsoldering techniques that are essential for those looking to refine their skills and tackle more complex repairs. Mastery of these techniques not only enhances the quality of work but also significantly increases efficiency, allowing technicians to handle intricate tasks with greater confidence.

To begin with, one of the most critical advanced techniques is the use of hot air rework stations. These devices provide a controlled flow of heated air, which is instrumental in desoldering and soldering components without the risk of damaging surrounding parts. Understanding the appropriate temperature settings and airflow is vital, as excessive heat can lead to delamination of circuit boards or damage to sensitive components. Practicing with various nozzle sizes can also help in achieving precision when working on densely populated boards.

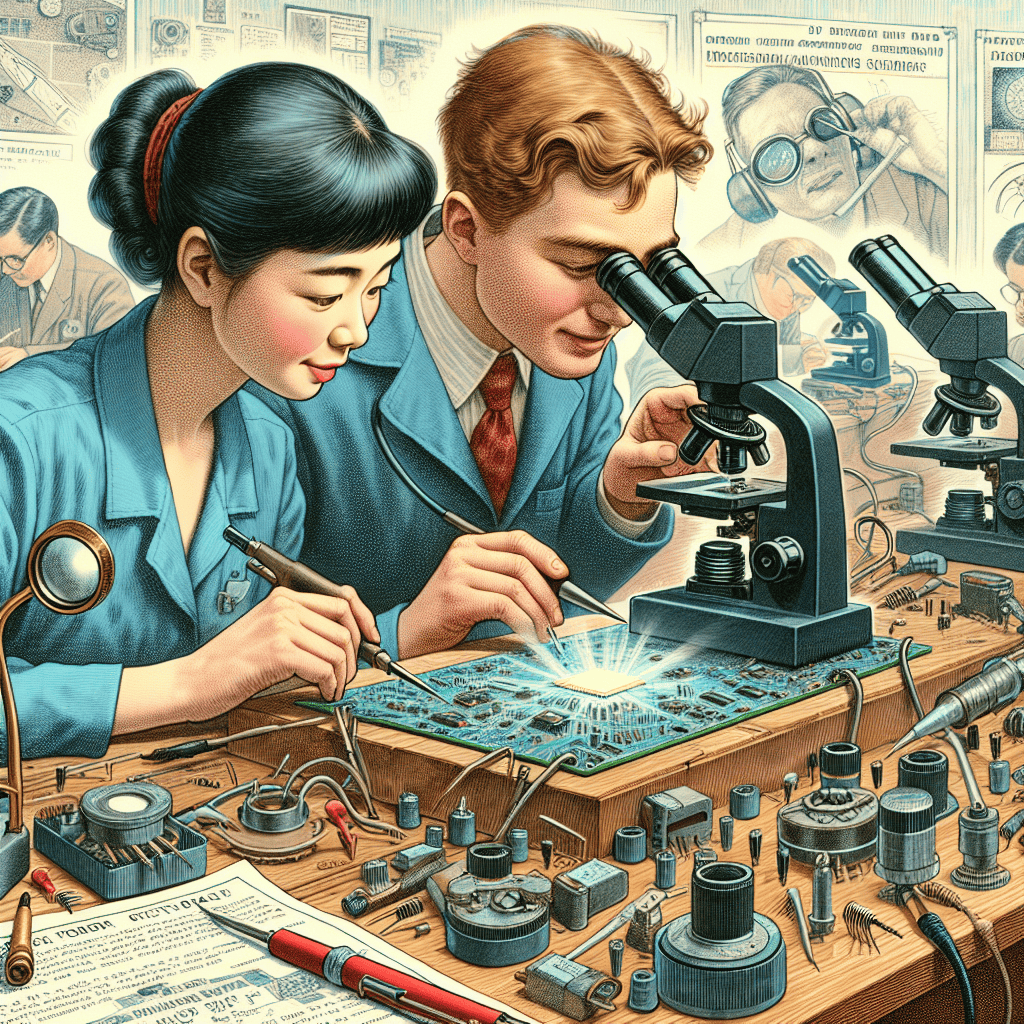

In addition to hot air rework, mastering the art of using a microscope is paramount. A high-quality microscope allows for detailed inspection of solder joints and components, ensuring that technicians can identify issues that may not be visible to the naked eye. This level of scrutiny is particularly important when working with fine-pitch components, where even the slightest misalignment can lead to functional failures. By developing the ability to work under magnification, technicians can enhance their accuracy and ultimately improve the reliability of their repairs.

Furthermore, the technique of using solder paste is another advanced method that warrants attention. Solder paste, which consists of tiny solder balls suspended in a flux medium, is particularly useful for surface mount technology (SMT) applications. Applying solder paste accurately requires practice, as it is essential to achieve the right amount on each pad to ensure a solid connection without creating bridges between adjacent pads. Once applied, the components can be placed with precision, and the assembly can be reflowed using a hot air station or a reflow oven, resulting in a clean and professional finish.

Transitioning from solder paste, the importance of proper flux application cannot be overstated. Flux plays a crucial role in the soldering process by preventing oxidation and promoting better wetting of the solder. Advanced technicians often experiment with different types of flux, such as no-clean or water-soluble, to determine which best suits their specific applications. Understanding the properties of each type of flux and how they interact with various solder materials can significantly impact the quality of the final product.

Moreover, as we delve deeper into advanced techniques, the significance of thermal management becomes increasingly apparent. Effective thermal management ensures that components are not subjected to excessive heat during the soldering process, which can lead to failure. Techniques such as using thermal pads or heat sinks can help dissipate heat away from sensitive areas, thereby preserving the integrity of the components involved.

Finally, as we conclude Day Five, it is essential to recognize that the journey to mastering advanced microsoldering techniques is ongoing. Continuous practice, coupled with a commitment to learning and adapting to new technologies, will ultimately lead to greater proficiency. By embracing these advanced techniques, technicians not only enhance their skill set but also contribute to the overall quality and reliability of electronic repairs, paving the way for a successful career in the ever-evolving field of microsoldering.

Troubleshooting Common Microsoldering Issues

On the fifth day of our microsoldering school, we delve into the critical aspect of troubleshooting common microsoldering issues. As students progress in their skills, it becomes increasingly important to recognize and address the challenges that may arise during the microsoldering process. Understanding these issues not only enhances the quality of work but also builds confidence in one’s ability to handle intricate repairs.

One of the most prevalent issues encountered in microsoldering is the occurrence of cold solder joints. These joints are characterized by a lack of proper adhesion between the solder and the components, often resulting in intermittent connections. To troubleshoot this problem, it is essential to first inspect the joint under a microscope. A cold joint typically appears dull and grainy, in contrast to a well-formed joint, which is shiny and smooth. If a cold joint is identified, the best course of action is to reheat the solder while ensuring that the components are adequately aligned. This process allows the solder to flow properly, creating a reliable connection.

Another common issue is the presence of solder bridges, which occur when excess solder creates an unintended connection between two adjacent pads or components. This can lead to short circuits and malfunctioning devices. To address solder bridges, one must carefully examine the affected area under magnification. If a bridge is detected, it can be removed using a solder wick or a desoldering pump. Applying heat to the bridge while simultaneously placing the solder wick over it allows the excess solder to be absorbed, restoring the integrity of the circuit.

In addition to these issues, students may also encounter problems related to component damage during the soldering process. This can happen if excessive heat is applied, leading to the destruction of sensitive components. To mitigate this risk, it is crucial to utilize proper soldering techniques, such as using a temperature-controlled soldering iron and applying heat only for the necessary duration. If a component is damaged, it is vital to replace it with a compatible part, ensuring that the new component is correctly oriented and securely soldered in place.

Moreover, students should be aware of the potential for lifted pads, which can occur when the adhesive holding a pad to the circuit board fails during soldering. This issue can complicate repairs, as it may require additional steps to restore functionality. In such cases, it is advisable to use a small amount of conductive adhesive to reattach the lifted pad, followed by careful soldering of the component to ensure a solid connection.

As we continue to explore the intricacies of microsoldering, it is essential to emphasize the importance of patience and precision. Each troubleshooting scenario presents an opportunity for learning and improvement. By systematically identifying and addressing these common issues, students can refine their skills and develop a deeper understanding of the microsoldering process.

In conclusion, mastering the techniques of microsoldering involves not only the ability to solder effectively but also the capacity to troubleshoot and resolve issues that may arise. By familiarizing oneself with common problems such as cold solder joints, solder bridges, component damage, and lifted pads, students can enhance their proficiency and confidence in this intricate craft. As we move forward in our training, let us embrace these challenges as stepping stones toward becoming skilled microsoldering technicians.

Essential Tools for Microsoldering Mastery

As the journey through microsoldering progresses, the fifth day marks a pivotal moment in mastering the essential techniques that define this intricate craft. At this stage, understanding the tools that facilitate precision and efficiency becomes paramount. The right tools not only enhance the quality of work but also significantly influence the learning curve for aspiring microsoldering technicians.

To begin with, a high-quality soldering iron is indispensable. A soldering iron equipped with a fine tip allows for the delicate manipulation of tiny components, ensuring that solder is applied precisely where needed. Temperature control is another critical feature; a soldering iron that can maintain a consistent temperature prevents damage to sensitive components and ensures optimal solder flow. As one becomes more adept at handling the soldering iron, the ability to execute intricate repairs and modifications improves dramatically.

In addition to the soldering iron, a reliable microscope is essential for microsoldering. The use of a microscope enables technicians to see minute details that are otherwise invisible to the naked eye. This enhanced visibility is crucial when working with small components, as it allows for accurate placement and soldering. Furthermore, a microscope with adjustable magnification provides flexibility, accommodating various tasks that may require different levels of detail. As one becomes accustomed to working under magnification, the confidence in executing complex repairs grows, leading to greater proficiency.

Moreover, a set of precision tweezers is vital in the microsoldering toolkit. These tweezers are designed to handle small components with care, allowing for accurate placement without the risk of damaging surrounding parts. The ergonomic design of precision tweezers ensures a comfortable grip, which is particularly important during extended periods of work. As one practices using these tools, the ability to manipulate components with finesse becomes second nature, further enhancing overall skill.

Another essential tool is the desoldering pump, which plays a crucial role in the repair process. This device allows technicians to remove excess solder or faulty components efficiently. Mastery of the desoldering pump is critical, as improper use can lead to damage to the circuit board or surrounding components. Therefore, practicing the technique of desoldering is as important as soldering itself, as it equips technicians with the ability to correct mistakes and refine their work.

In addition to these primary tools, a quality soldering mat is often overlooked but is equally important. A soldering mat provides a safe and organized workspace, protecting both the components and the work surface from heat damage. Furthermore, it often features anti-static properties, which are essential for preventing static discharge that can harm sensitive electronic parts. A well-organized workspace fosters efficiency and focus, allowing technicians to concentrate on the task at hand without unnecessary distractions.

Finally, as one delves deeper into the world of microsoldering, the importance of continuous practice cannot be overstated. Each tool, from the soldering iron to the desoldering pump, requires familiarity and skill to wield effectively. By dedicating time to practice with these essential tools, technicians can refine their techniques, leading to greater confidence and competence in their work. As the fifth day of training concludes, it becomes clear that mastery in microsoldering is not solely about understanding the techniques but also about developing a deep familiarity with the tools that make those techniques possible. Through diligent practice and a commitment to learning, aspiring microsoldering technicians can pave the way for a successful career in this specialized field.

Best Practices for Microsoldering Precision

On the fifth day of our microsoldering school, the focus shifts to mastering the techniques that underpin precision in this intricate craft. As students delve deeper into the nuances of microsoldering, it becomes increasingly clear that best practices are not merely suggestions but essential components of achieving high-quality results. The importance of a steady hand cannot be overstated; however, it is equally vital to cultivate an environment conducive to precision work. This includes ensuring that the workspace is well-lit and organized, as clutter can lead to distractions and mistakes. A clean, well-maintained area allows for better focus and minimizes the risk of losing small components, which are often critical to the success of a repair.

Moreover, the selection of tools plays a pivotal role in achieving precision. High-quality soldering irons with fine tips are indispensable for microsoldering tasks, as they allow for greater control over the application of heat. Students are encouraged to familiarize themselves with various types of solder and flux, as the right combination can significantly enhance the quality of the joint. For instance, using lead-free solder may be more environmentally friendly, but it often requires higher temperatures and different techniques compared to traditional lead-based solder. Understanding these differences is crucial for adapting to the specific requirements of each project.

In addition to tool selection, the technique of applying solder is a critical aspect of microsoldering precision. Students learn that the goal is to create a clean, shiny joint that is neither too large nor too small. This balance is achieved through practice and an understanding of the properties of solder. For example, applying too much solder can lead to bridging, where excess solder connects unintended points on a circuit board, while too little can result in weak connections that may fail under stress. Therefore, mastering the art of solder application involves not only the physical act of soldering but also a keen awareness of the materials involved.

Furthermore, the practice of pre-tinning components before soldering is emphasized as a best practice. Pre-tinning involves applying a small amount of solder to the component leads or pads before making the final connection. This technique not only improves the flow of solder during the actual soldering process but also helps to ensure a more reliable electrical connection. Students are guided through exercises that reinforce this practice, allowing them to develop muscle memory and confidence in their abilities.

As the day progresses, the importance of patience and attention to detail becomes increasingly apparent. Microsoldering is not a race; rather, it is a meticulous process that rewards those who take their time to ensure each step is executed flawlessly. Students are encouraged to adopt a mindset of continuous improvement, where each mistake is viewed as an opportunity to learn and refine their skills. This approach fosters a culture of excellence, where precision is not just a goal but a standard.

In conclusion, the fifth day of microsoldering school serves as a pivotal moment in the journey toward mastering this intricate craft. By adhering to best practices, such as maintaining an organized workspace, selecting appropriate tools, applying solder with care, and embracing a patient mindset, students lay the foundation for precision in their work. As they continue to hone their skills, the lessons learned on this day will undoubtedly resonate throughout their future endeavors in the world of microsoldering.

Real-World Applications of Microsoldering Skills

As students progress through their training in microsoldering, the fifth day marks a pivotal moment where theoretical knowledge begins to translate into practical skills. This day is dedicated to exploring the real-world applications of microsoldering techniques, emphasizing the significance of these skills in various industries. Understanding the practical implications of microsoldering not only enhances the learning experience but also prepares students for the challenges they will face in their professional careers.

One of the most prominent applications of microsoldering is in the field of electronics repair. As technology continues to advance, devices such as smartphones, tablets, and laptops have become integral to daily life. However, with increased complexity comes a higher likelihood of component failure. Microsoldering enables technicians to repair intricate circuit boards, replacing damaged components with precision. This skill not only extends the lifespan of devices but also contributes to sustainability by reducing electronic waste. As students practice their microsoldering techniques, they gain insight into the importance of their work in promoting environmental responsibility.

In addition to electronics repair, microsoldering plays a crucial role in the manufacturing sector. Many modern devices rely on densely packed circuit boards, where components are often miniaturized to save space. In this context, the ability to perform microsoldering is essential for assembling and maintaining these intricate systems. Students learn that their skills can be applied in various manufacturing environments, from consumer electronics to medical devices. The demand for skilled microsoldering technicians in these industries is growing, as companies seek to ensure the reliability and functionality of their products.

Moreover, the medical field presents another significant application for microsoldering skills. Medical devices, such as pacemakers and diagnostic equipment, often contain delicate electronic components that require precise soldering techniques. As students delve into this aspect of microsoldering, they recognize the critical nature of their work; a single error could have serious implications for patient safety. This realization instills a sense of responsibility and professionalism, reinforcing the importance of mastering the techniques taught in the microsoldering school.

Furthermore, the automotive industry has also begun to embrace microsoldering as vehicles become increasingly reliant on electronic systems. From advanced driver-assistance systems to infotainment units, the complexity of automotive electronics necessitates skilled technicians who can perform precise repairs and modifications. As students explore this application, they understand that their microsoldering skills can open doors to diverse career opportunities, allowing them to contribute to the evolving landscape of automotive technology.

In addition to these industries, the burgeoning field of robotics also benefits from microsoldering expertise. As robots become more sophisticated and integrated into various sectors, the need for skilled technicians to assemble and repair robotic systems is on the rise. Students are encouraged to consider how their training in microsoldering can position them at the forefront of this exciting field, where innovation and precision are paramount.

In conclusion, the fifth day of microsoldering school serves as a crucial bridge between theory and practice, highlighting the real-world applications of the skills being developed. By understanding the diverse industries that rely on microsoldering, students can appreciate the value of their training and the impact they can have on technology and society. As they refine their techniques, they are not only preparing for successful careers but also contributing to a more sustainable and technologically advanced future.

Building a Portfolio: Showcasing Your Microsoldering Projects

As the fifth day of the microsoldering school unfolds, students find themselves at a pivotal juncture in their educational journey. Having acquired a solid foundation in the intricate techniques of microsoldering, the focus now shifts toward building a portfolio that effectively showcases their projects. This portfolio serves not only as a testament to their skills but also as a vital tool for future employment opportunities and professional growth.

To begin with, it is essential to understand the significance of a well-curated portfolio. A portfolio is more than just a collection of completed projects; it is a narrative that illustrates the evolution of a student’s capabilities and creativity. As students reflect on their work, they should aim to select projects that highlight a range of skills, from basic repairs to more complex soldering tasks. This diversity not only demonstrates technical proficiency but also showcases adaptability and problem-solving abilities, which are highly valued in the field.

Moreover, when compiling their portfolios, students should consider the presentation of their work. High-quality photographs are crucial, as they capture the intricate details of each project. Clear, well-lit images allow potential employers or clients to appreciate the precision and care that went into each piece of work. Additionally, including before-and-after images can effectively illustrate the impact of their skills, providing a visual narrative that enhances the overall presentation.

In addition to visual elements, written descriptions accompanying each project can further enrich the portfolio. These descriptions should detail the objectives of the project, the techniques employed, and any challenges encountered along the way. By articulating their thought processes and the rationale behind their choices, students can convey a deeper understanding of their craft. This narrative aspect not only engages the viewer but also demonstrates critical thinking and reflective practice, which are essential components of professional development.

Furthermore, students should not overlook the importance of including any relevant certifications or accolades they have received during their training. These credentials serve to validate their skills and commitment to the field, providing an additional layer of credibility to their portfolio. As they progress in their careers, students may also want to consider documenting any continuing education or specialized training they pursue, as this reflects a dedication to lifelong learning and professional growth.

As students prepare to present their portfolios, they should also think about their target audience. Whether seeking employment in a repair shop, a tech company, or even considering freelance opportunities, tailoring the portfolio to meet the expectations of potential employers can significantly enhance its effectiveness. Understanding the specific skills and experiences that are valued in different contexts allows students to emphasize the most relevant projects and achievements.

In conclusion, building a portfolio is a critical step in the journey of mastering microsoldering techniques. By thoughtfully selecting projects, presenting them with high-quality visuals, and providing insightful descriptions, students can create a compelling narrative that showcases their skills and experiences. As they move forward in their careers, this portfolio will not only serve as a reflection of their hard work and dedication but also as a powerful tool for opening doors to new opportunities in the ever-evolving field of microsoldering.

Q&A

1. **What is the focus of Day Five in the Microsoldering School?**

Mastering advanced microsoldering techniques and refining skills learned in previous days.

2. **What specific techniques are covered on Day Five?**

Techniques such as advanced component removal, reballing, and complex circuit repairs.

3. **Are there any hands-on practice sessions on Day Five?**

Yes, students engage in extensive hands-on practice to apply the techniques learned.

4. **What tools are emphasized for use on Day Five?**

Precision tweezers, hot air rework stations, and microscopes are emphasized.

5. **Is there a review session on Day Five?**

Yes, there is a review session to reinforce key concepts and techniques from the week.

6. **What is the expected outcome by the end of Day Five?**

Students should be able to confidently perform advanced microsoldering tasks and troubleshoot common issues.On Day Five of Microsoldering School, participants honed their skills by mastering advanced techniques essential for precision repairs. Through hands-on practice and expert guidance, students gained confidence in their ability to tackle complex soldering tasks, reinforcing their understanding of tools and materials. This culmination of training not only solidified their technical proficiency but also prepared them for real-world applications in the microsoldering field.