The MacBook Pro M4 Pro Teardown reveals a continuation of familiar repair challenges that have characterized previous models. As Apple enthusiasts and repair professionals delve into the intricacies of the latest iteration, the M4 Pro, they encounter a blend of innovative design and persistent obstacles. This teardown provides a detailed examination of the internal components, highlighting both advancements and the ongoing complexities associated with repairability. From the tightly integrated architecture to the proprietary screws and adhesive, the M4 Pro maintains Apple’s trend of prioritizing sleek design over ease of access. This analysis not only sheds light on the technical prowess of Apple’s engineering but also underscores the ongoing debate surrounding consumer repair rights and the balance between innovation and accessibility.

Understanding the Internal Layout: A Close Look at the MacBook Pro M4 Pro

The MacBook Pro M4 Pro, Apple’s latest iteration in its line of high-performance laptops, has garnered significant attention for its advanced features and impressive specifications. However, as with previous models, the internal layout presents familiar challenges for those interested in repair and maintenance. A close examination of the MacBook Pro M4 Pro’s internal components reveals both continuity and change, offering insights into Apple’s design philosophy and the practical implications for users and technicians alike.

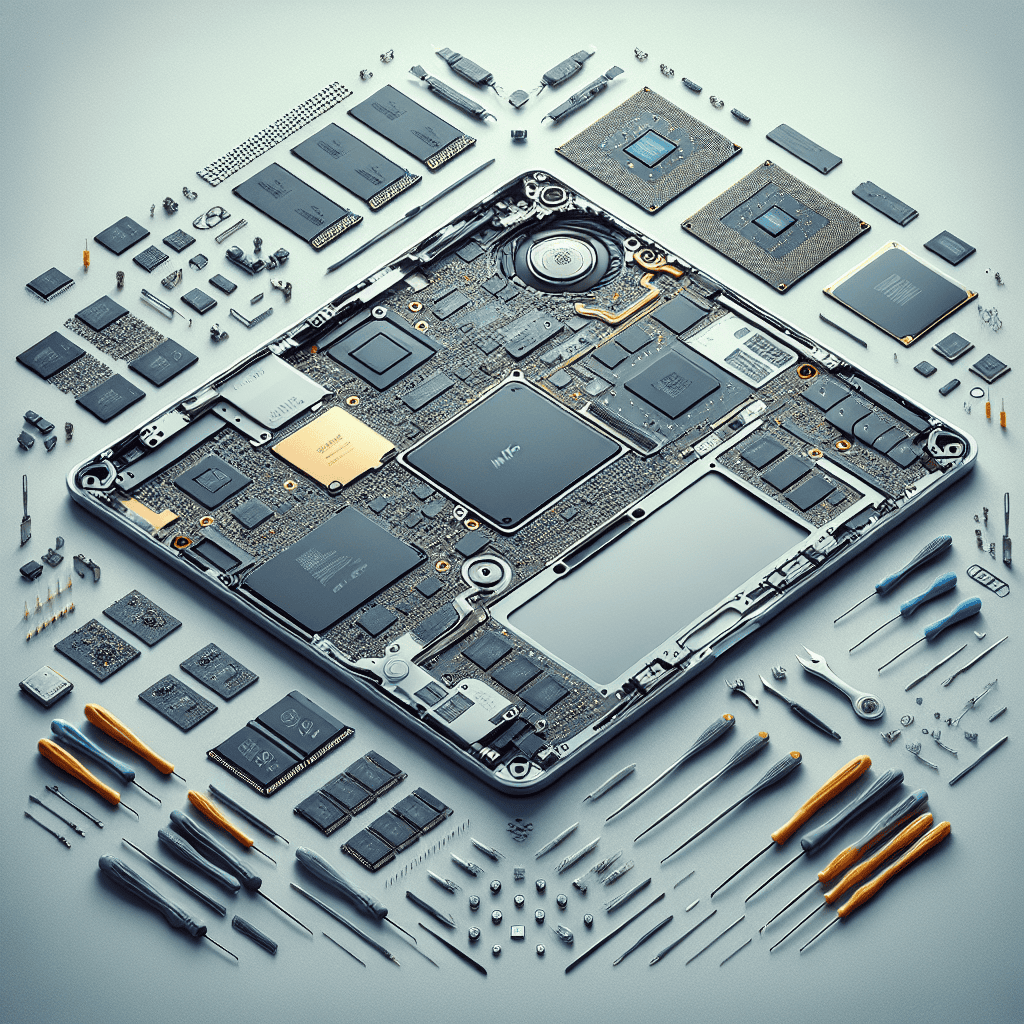

Upon opening the MacBook Pro M4 Pro, one is immediately struck by the meticulous organization of its internal components. The layout is a testament to Apple’s commitment to maximizing space efficiency while maintaining a sleek and compact design. The logic board, a critical component, is centrally located, surrounded by a carefully arranged array of other essential parts. This strategic placement not only optimizes performance but also reflects Apple’s ongoing efforts to streamline the internal architecture of its devices.

Transitioning to the battery, the MacBook Pro M4 Pro continues the trend of using a custom-shaped lithium-polymer battery. This design choice allows for a larger battery capacity, thereby extending the device’s operational life on a single charge. However, it also presents a challenge for repairability. The adhesive used to secure the battery in place is notoriously difficult to remove, a characteristic that has been a point of contention among repair professionals. This adhesive, while ensuring stability and safety, complicates the process of battery replacement, necessitating specialized tools and techniques.

Moving on to the cooling system, the MacBook Pro M4 Pro features an advanced thermal management setup. The inclusion of a larger heat sink and improved fan design highlights Apple’s focus on maintaining optimal performance under heavy workloads. This enhancement is particularly beneficial for professionals who rely on the MacBook Pro for resource-intensive tasks. Nevertheless, the integration of these components into the compact chassis poses challenges for those attempting to service or replace them. The intricate assembly requires a high level of precision and expertise, underscoring the complexity of repairs.

In terms of connectivity, the MacBook Pro M4 Pro offers a range of ports, including Thunderbolt 4 and USB-C, which are soldered directly onto the logic board. This design choice, while contributing to the device’s slim profile, complicates repairs. Should a port become damaged, the entire logic board may need replacement, significantly increasing repair costs. This aspect of the design reflects a broader trend in consumer electronics, where the pursuit of thinner and lighter devices often comes at the expense of repairability.

Furthermore, the integration of Apple’s proprietary M4 Pro chip into the MacBook Pro marks a significant advancement in processing power and efficiency. This chip, designed in-house, is a key differentiator for Apple, offering unparalleled performance. However, its integration also means that repairs involving the chip are highly specialized, often requiring direct support from Apple or authorized service providers.

In conclusion, the MacBook Pro M4 Pro’s internal layout is a blend of innovation and continuity, reflecting Apple’s design priorities and the inherent challenges of modern electronics repair. While the device offers remarkable performance and efficiency, its repairability remains a complex issue. As technology continues to evolve, striking a balance between cutting-edge design and practical repair solutions will be crucial for manufacturers and consumers alike.

Key Components Revealed: What’s Inside the MacBook Pro M4 Pro?

The MacBook Pro M4 Pro has captured the attention of tech enthusiasts and professionals alike, promising enhanced performance and cutting-edge features. However, as with any new release, curiosity about its internal components and repairability is inevitable. A recent teardown of the MacBook Pro M4 Pro reveals a blend of familiar challenges and intriguing insights into its key components, offering a glimpse into what makes this device tick.

Upon opening the sleek aluminum chassis, the first noticeable feature is the M4 Pro chip, the powerhouse behind the MacBook’s impressive capabilities. This chip, designed by Apple, integrates the CPU, GPU, and neural engine, promising a seamless experience for users. Its compact design and efficient architecture are a testament to Apple’s commitment to innovation. However, the integration of these components also presents a challenge for repairability, as replacing or upgrading individual parts becomes increasingly complex.

Transitioning to the storage and memory components, the MacBook Pro M4 Pro continues the trend of soldered RAM and SSD. This design choice, while beneficial for performance and space efficiency, limits the user’s ability to upgrade these components post-purchase. Consequently, potential buyers must carefully consider their storage and memory needs at the time of purchase, as future modifications are not feasible. This approach underscores Apple’s focus on creating a streamlined and efficient device, albeit at the cost of user flexibility.

The battery, a critical component for any portable device, is another area of interest in the teardown. The MacBook Pro M4 Pro features a high-capacity lithium-polymer battery, designed to provide extended usage time. However, the battery is secured with adhesive, making replacement a meticulous task that requires precision and patience. This design choice, while ensuring a compact and lightweight device, poses a challenge for those seeking to perform their own repairs or replacements.

Moving on to the cooling system, the MacBook Pro M4 Pro employs an advanced thermal management system to maintain optimal performance. The inclusion of a sophisticated heat pipe and fan assembly highlights Apple’s dedication to ensuring that the device remains cool under heavy workloads. However, accessing and servicing these components requires a careful disassembly process, further emphasizing the complexity of repairs.

The display assembly, a hallmark of Apple’s design, is another focal point in the teardown. The Retina display, known for its vibrant colors and sharp resolution, is integrated with the top case, making it a single unit. This integration enhances the device’s aesthetic appeal and structural integrity but complicates repairs, as any damage to the display necessitates replacing the entire assembly.

In conclusion, the MacBook Pro M4 Pro teardown reveals a device that balances cutting-edge technology with familiar repair challenges. While the integration of components like the M4 Pro chip and soldered memory enhances performance, it also limits user repairability. The adhesive-secured battery and integrated display assembly further contribute to the complexity of repairs. As Apple continues to push the boundaries of design and performance, users must weigh the benefits of these advancements against the potential challenges of maintaining and repairing their devices. This delicate balance between innovation and repairability remains a defining characteristic of Apple’s approach to product design.

Repairability Score: How the MacBook Pro M4 Pro Compares to Previous Models

The MacBook Pro M4 Pro, Apple’s latest iteration in its line of high-performance laptops, has garnered significant attention for its impressive specifications and sleek design. However, as with previous models, the question of repairability remains a critical concern for both consumers and repair professionals. In examining the repairability score of the MacBook Pro M4 Pro, it is essential to compare it to its predecessors to understand how Apple has addressed—or perhaps neglected—repair challenges that have long been associated with its products.

To begin with, the MacBook Pro M4 Pro continues the trend of prioritizing a compact and seamless design, which inevitably impacts its repairability. Much like the earlier M1 and M2 models, the M4 Pro features a tightly integrated architecture that makes accessing internal components a daunting task. The use of proprietary screws and adhesive to secure parts such as the battery and display further complicates the disassembly process. Consequently, these design choices result in a lower repairability score, as they require specialized tools and expertise to perform even basic repairs.

Transitioning to the internal components, the MacBook Pro M4 Pro showcases a similar layout to its predecessors, with the logic board, RAM, and storage soldered directly onto the board. This design decision, while beneficial for performance and space-saving, significantly limits the upgradability and repair options available to users. In contrast, older models, such as those from the pre-Retina era, offered more flexibility with replaceable RAM and storage, allowing users to extend the lifespan of their devices with relative ease. The soldered components in the M4 Pro, however, mean that any failure in these areas necessitates a complete logic board replacement, which is both costly and environmentally unfriendly.

Moreover, the battery in the MacBook Pro M4 Pro, although slightly more accessible than in some previous models, still presents challenges. The use of strong adhesive to secure the battery in place requires careful handling during removal to avoid damage. While Apple has made some strides in providing battery replacement kits for certain models, the process remains intricate and time-consuming, contributing to a lower repairability score. In comparison, laptops from other manufacturers often feature batteries that can be easily swapped out, highlighting a significant area where Apple could improve.

Despite these challenges, it is worth noting that Apple has made some efforts to enhance repairability in recent years. The introduction of the Self Service Repair program, which provides access to genuine parts and repair manuals, marks a positive step towards empowering consumers to undertake their own repairs. However, the complexity of the MacBook Pro M4 Pro’s design means that this initiative may have limited impact on improving its overall repairability score.

In conclusion, the MacBook Pro M4 Pro, while a technological marvel in terms of performance and design, continues to face familiar repair challenges that have plagued previous models. The tightly integrated architecture, soldered components, and use of adhesive all contribute to a lower repairability score compared to older models that offered more user-friendly repair options. While Apple’s efforts to support self-repair are commendable, the inherent design choices in the M4 Pro suggest that significant improvements in repairability may require a fundamental shift in design philosophy. As consumers increasingly prioritize sustainability and longevity in their purchasing decisions, addressing these repairability challenges will be crucial for Apple in future iterations of its MacBook Pro line.

Common Repair Challenges: Navigating the MacBook Pro M4 Pro Teardown

The MacBook Pro M4 Pro, Apple’s latest iteration in its line of high-performance laptops, has garnered significant attention for its impressive specifications and sleek design. However, as with previous models, the teardown of this device reveals a series of familiar repair challenges that continue to pose difficulties for technicians and DIY enthusiasts alike. Understanding these challenges is crucial for anyone considering repairs or modifications to their device.

To begin with, the MacBook Pro M4 Pro maintains Apple’s tradition of prioritizing a compact and seamless design, which inevitably complicates the disassembly process. The device is held together by a series of proprietary screws, requiring specialized tools for removal. This initial barrier is a common theme in Apple’s design philosophy, aimed at ensuring a sleek exterior but often frustrating those attempting to access the internal components. Once inside, the layout of the components presents another layer of complexity. The tightly packed internals, while efficient in terms of space utilization, leave little room for maneuvering, making it challenging to replace or repair individual parts without risking damage to adjacent components.

Moreover, the integration of components in the MacBook Pro M4 Pro further complicates repair efforts. For instance, the soldered RAM and storage mean that upgrades are not an option post-purchase, a design choice that has been a point of contention among users who prefer the flexibility of upgrading their devices over time. This integration is a double-edged sword; while it contributes to the device’s performance and reliability, it also limits the user’s ability to customize or repair their laptop independently.

In addition to these challenges, the battery replacement process in the MacBook Pro M4 Pro remains a daunting task. The battery is secured with strong adhesive, a feature that has been consistent in previous models. Removing the battery without causing damage requires patience and precision, often necessitating the use of isopropyl alcohol or specialized tools to dissolve the adhesive. This process not only increases the time and effort required for battery replacement but also raises the risk of accidental damage to the battery or other components.

Furthermore, the display assembly in the MacBook Pro M4 Pro is another area where repair challenges persist. The display is a single unit, meaning that if any part of it fails, such as the backlight or the screen itself, the entire assembly must be replaced. This not only increases the cost of repairs but also contributes to electronic waste, as functional components are discarded along with the faulty ones.

Despite these challenges, it is important to acknowledge the strides Apple has made in terms of repairability. The company has introduced a self-service repair program, providing access to genuine parts and manuals for those who wish to undertake repairs themselves. However, the complexity of the MacBook Pro M4 Pro’s design means that even with these resources, repairs remain a daunting prospect for many.

In conclusion, while the MacBook Pro M4 Pro offers cutting-edge technology and performance, it also presents a series of familiar repair challenges that users must navigate. The intricate design, integrated components, and adhesive-secured battery are just a few of the hurdles that make repairs difficult. As technology continues to advance, the balance between design innovation and repairability remains a critical consideration for both manufacturers and consumers.

Tools and Techniques: Essential Gear for MacBook Pro M4 Pro Repairs

The MacBook Pro M4 Pro has recently hit the market, and as with any new release from Apple, it has sparked a flurry of interest among tech enthusiasts and repair professionals alike. While the device boasts impressive performance enhancements and sleek design updates, it also presents familiar challenges when it comes to repairs. For those looking to delve into the inner workings of this latest model, understanding the essential tools and techniques is crucial for successful repairs.

To begin with, the MacBook Pro M4 Pro, like its predecessors, requires a specialized set of tools for disassembly and repair. One of the most indispensable tools is the precision screwdriver set, which includes Pentalobe, Torx, and Phillips screwdrivers. These are necessary for removing the various screws that secure the device’s components. The Pentalobe screwdriver, in particular, is essential for accessing the internal components, as Apple continues to use proprietary screws to deter unauthorized repairs.

In addition to screwdrivers, a spudger is another vital tool for any repair technician. This non-conductive tool is used to safely pry open the casing and disconnect delicate connectors without causing damage. The spudger’s versatility makes it an invaluable asset, especially when dealing with the tightly packed internals of the MacBook Pro M4 Pro. Furthermore, a suction cup can be employed to gently lift the display assembly, allowing for easier access to the internal components.

Transitioning to the internal components, the MacBook Pro M4 Pro’s logic board is a critical area that requires careful handling. An anti-static wrist strap is recommended to prevent electrostatic discharge, which can irreparably damage sensitive components. Additionally, a magnifying glass or head-mounted magnifier can be beneficial for inspecting small parts and ensuring precise work, particularly when dealing with the intricate soldering points on the logic board.

Moreover, thermal paste and a heat gun are essential for those looking to replace or upgrade the device’s cooling system. The M4 Pro’s advanced processor generates significant heat, necessitating efficient thermal management. Reapplying thermal paste can improve heat dissipation, while a heat gun can assist in loosening adhesive bonds without damaging the surrounding components.

As we consider the battery replacement process, it is important to note that the MacBook Pro M4 Pro’s battery is secured with strong adhesive. A plastic card or specialized adhesive remover can be used to carefully separate the battery from the chassis. Patience and precision are key during this process to avoid puncturing the battery, which could lead to hazardous situations.

Finally, reassembly is a crucial step that requires attention to detail. Ensuring that all screws are returned to their original positions and that connectors are securely fastened is vital for the device’s functionality. A systematic approach, such as organizing screws and components in a logical sequence, can aid in this process.

In conclusion, while the MacBook Pro M4 Pro presents familiar repair challenges, equipping oneself with the right tools and techniques can facilitate successful repairs. By understanding the nuances of this latest model and employing a methodical approach, repair professionals can navigate the complexities of the device with confidence. As technology continues to evolve, staying informed and prepared remains essential for those dedicated to mastering the art of MacBook repairs.

Future Implications: What the M4 Pro Teardown Means for Apple Repairability

The recent teardown of the MacBook Pro M4 Pro has once again brought to light the ongoing challenges associated with the repairability of Apple’s flagship laptops. As technology enthusiasts and repair professionals delve into the intricacies of the latest model, it becomes evident that while Apple continues to push the boundaries of innovation, it also maintains a consistent approach to design that complicates repair efforts. This raises important questions about the future implications for both consumers and the broader tech industry.

To begin with, the M4 Pro’s internal architecture showcases Apple’s commitment to integrating cutting-edge technology within a sleek and compact design. The new model features the highly anticipated M4 Pro chip, which promises enhanced performance and efficiency. However, this advancement comes at a cost to repairability. The chip is soldered directly onto the motherboard, a design choice that has become a hallmark of Apple’s recent products. This decision, while beneficial for performance, poses significant challenges for repair technicians who may need to replace or upgrade components.

Moreover, the battery, a critical component for any portable device, remains glued into the chassis. This adhesive approach, although it contributes to the device’s slim profile, complicates battery replacement. Users who wish to extend the lifespan of their MacBook Pro by replacing the battery themselves are likely to encounter difficulties, as removing the adhesive without damaging other components requires specialized tools and expertise. Consequently, this design choice may lead to increased reliance on Apple’s official repair services, which can be costly and time-consuming.

In addition to these challenges, the M4 Pro’s display assembly is another area where repairability is compromised. The display is fused with the glass, making it difficult to replace just the screen without replacing the entire assembly. This not only increases repair costs but also contributes to electronic waste, as more components are discarded rather than repaired. As environmental concerns continue to gain prominence, this aspect of Apple’s design philosophy may face increased scrutiny from both consumers and regulatory bodies.

Despite these familiar repair challenges, it is important to acknowledge the potential benefits of Apple’s design choices. The integration of components and the use of adhesives contribute to the device’s durability and resistance to dust and moisture. These factors enhance the overall user experience by reducing the likelihood of damage from everyday use. However, the trade-off between durability and repairability remains a contentious issue, with consumers increasingly advocating for devices that are both robust and easy to repair.

Looking ahead, the implications of the M4 Pro teardown extend beyond individual consumers to the broader tech industry. As Apple continues to set trends in design and technology, other manufacturers may follow suit, adopting similar approaches that prioritize performance and aesthetics over repairability. This could lead to a shift in consumer expectations, where repairability becomes a secondary consideration. Alternatively, the growing right-to-repair movement may gain momentum, pushing manufacturers to reconsider their design choices and prioritize sustainability and repairability.

In conclusion, the MacBook Pro M4 Pro teardown highlights the ongoing tension between innovation and repairability in Apple’s product design. While the latest model offers impressive performance and durability, it also presents familiar challenges for repair professionals and consumers alike. As the tech industry evolves, the balance between cutting-edge technology and user-friendly repairability will remain a critical consideration, shaping the future of consumer electronics and influencing the choices of both manufacturers and consumers.

Q&A

1. **What are the key components revealed in the MacBook Pro M4 Pro teardown?**

– The teardown reveals key components such as the M4 Pro chip, unified memory, SSD storage, cooling system, and the battery.

2. **How does the cooling system in the MacBook Pro M4 Pro compare to previous models?**

– The cooling system in the M4 Pro is similar to previous models, featuring dual fans and heat pipes, but with slight optimizations for improved thermal management.

3. **What challenges are associated with repairing the MacBook Pro M4 Pro?**

– Repair challenges include the use of proprietary screws, soldered components like RAM and SSD, and the difficulty in accessing internal parts due to the compact design.

4. **Is the battery in the MacBook Pro M4 Pro easily replaceable?**

– The battery is not easily replaceable as it is glued in place, requiring careful removal and replacement, which can be challenging for non-professionals.

5. **Are there any improvements in repairability in the MacBook Pro M4 Pro compared to earlier models?**

– There are minimal improvements in repairability, with most components still being difficult to access and replace, maintaining a similar level of repair complexity as earlier models.

6. **What tools are necessary for performing a teardown of the MacBook Pro M4 Pro?**

– Necessary tools include a Pentalobe screwdriver, Torx screwdrivers, spudgers, tweezers, and suction handles to safely open and disassemble the device.The MacBook Pro M4 Pro teardown reveals that while Apple has made some strides in improving the repairability of its devices, familiar challenges persist. The device continues to feature proprietary components and complex assembly techniques that complicate repairs for the average user. Key components like the battery and display remain difficult to replace without specialized tools and expertise. Despite some modular elements, the overall design still prioritizes sleekness and performance over ease of repair. This suggests that while Apple acknowledges the right-to-repair movement, significant barriers remain for those seeking to perform DIY repairs on the latest MacBook Pro models.