The Galaxy S25 Ultra, Samsung’s flagship smartphone, showcases cutting-edge technology and design, but its disassembly reveals a complex interplay between rapid battery solutions and slow advancements in repairability. As consumers increasingly prioritize sustainability and longevity in their devices, understanding the internal structure of the S25 Ultra becomes crucial. This disassembly highlights the innovative battery management features that allow for quick replacements, yet also underscores the challenges posed by tightly integrated components that hinder straightforward repairs. Exploring these aspects provides valuable insights into the evolving landscape of smartphone design and user experience.

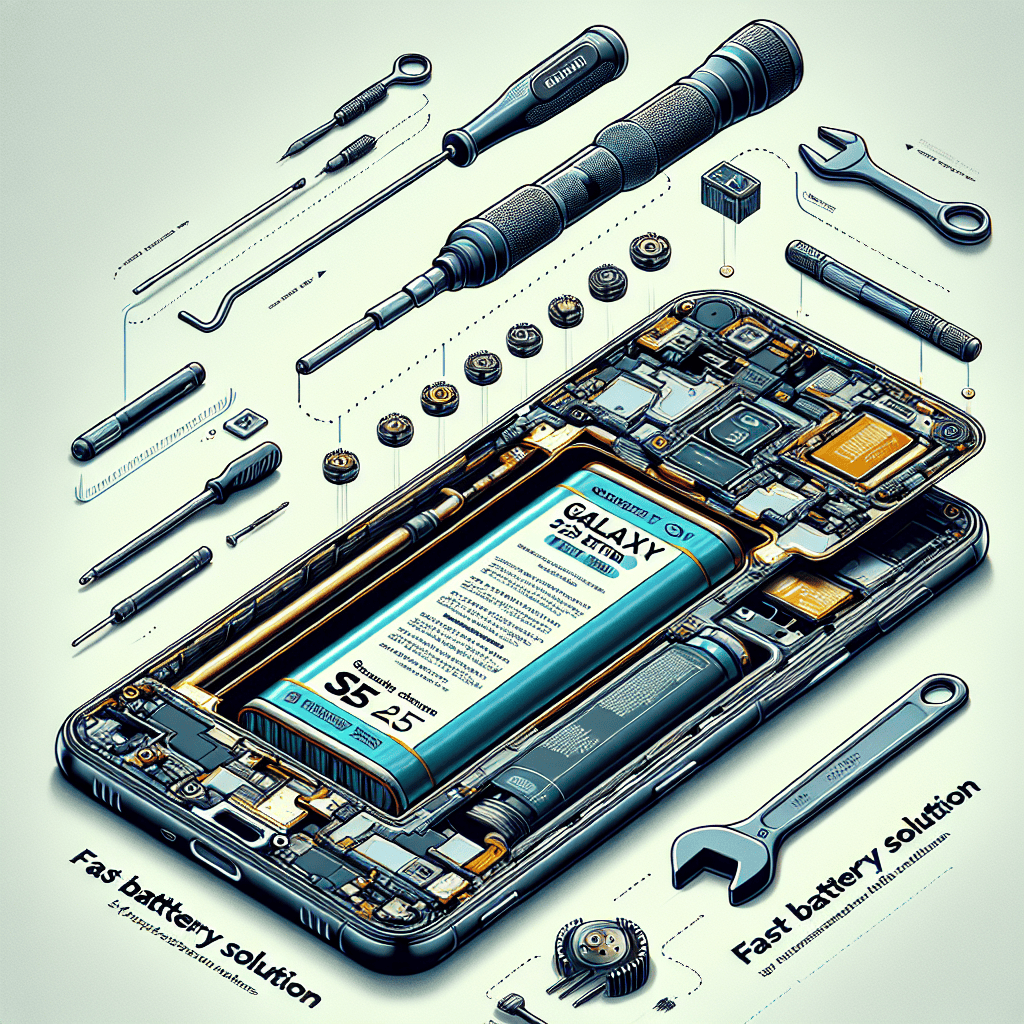

Galaxy S25 Ultra Disassembly: A Step-by-Step Guide

The Galaxy S25 Ultra, Samsung’s flagship smartphone, has garnered attention not only for its advanced features but also for its intricate design. Disassembling this device reveals insights into its construction and the challenges associated with repairability. This step-by-step guide aims to provide a comprehensive overview of the disassembly process, highlighting both the innovative battery solution and the slower advancements in repairability.

To begin the disassembly, one must first ensure that the device is powered off to prevent any electrical damage. Using a heat gun or a specialized heating pad, the edges of the phone are gently warmed to soften the adhesive that holds the glass back in place. This step is crucial, as it minimizes the risk of cracking the glass during removal. Once adequately heated, a plastic opening tool is inserted into the seam between the glass back and the frame, allowing for careful prying. Gradually working around the edges, the adhesive gives way, and the back cover can be lifted off, revealing the internal components.

Upon removing the back cover, the first notable feature is the battery, which is designed for easy access. Samsung has implemented a pull-tab mechanism that allows users to remove the battery without extensive disassembly. This innovation is particularly beneficial for those who may need to replace a depleted battery quickly. By simply pulling the tab, the battery detaches from its connectors, making it one of the more user-friendly aspects of the device. This design choice reflects a growing trend in the industry towards facilitating battery replacements, which is a significant improvement over previous models.

However, as one delves deeper into the device, the challenges of repairability become apparent. The motherboard, which houses critical components such as the processor and memory, is secured with multiple screws and additional adhesive. Removing the motherboard requires careful detachment of various connectors and components, including the camera modules and the display assembly. This process can be time-consuming and necessitates a level of technical skill that may not be accessible to the average user. Furthermore, the intricate layout of the internal components complicates reassembly, as each part must be meticulously returned to its original position.

Transitioning to the display, it is important to note that while the Galaxy S25 Ultra features a stunning AMOLED screen, its repairability is hindered by the strong adhesive used to secure it to the frame. Removing the display requires significant effort and precision, as any misstep can lead to damage. This aspect of the disassembly process highlights a critical area where advancements in repairability have not kept pace with other improvements in smartphone technology. While the battery solution is commendable, the overall design still poses challenges for those seeking to perform repairs independently.

In conclusion, the disassembly of the Galaxy S25 Ultra reveals a dual narrative: on one hand, the device showcases a fast and efficient battery replacement solution, while on the other, it underscores the ongoing struggle with repairability. As technology continues to evolve, it is essential for manufacturers to balance innovative designs with user-friendly repair options. The insights gained from disassembling the Galaxy S25 Ultra serve as a reminder of the complexities involved in modern smartphone construction and the need for continued advancements in making devices more accessible for repairs.

Fast Battery Solutions for the Galaxy S25 Ultra

The Galaxy S25 Ultra has garnered significant attention for its impressive features and performance, but one aspect that stands out is its battery solution. As smartphones continue to evolve, manufacturers are increasingly focused on enhancing battery efficiency and longevity. The Galaxy S25 Ultra exemplifies this trend, offering a fast battery solution that caters to the demands of modern users. With a robust battery capacity, the device is designed to support extensive usage without frequent recharging, which is a critical consideration for consumers who rely heavily on their devices throughout the day.

One of the key innovations in the Galaxy S25 Ultra’s battery technology is its rapid charging capability. This feature allows users to recharge their devices quickly, minimizing downtime and ensuring that they can return to their daily activities with minimal interruption. The integration of advanced charging protocols means that the device can achieve a significant percentage of battery life in a short period, making it particularly appealing for those who are always on the go. Furthermore, the inclusion of wireless charging options adds an extra layer of convenience, allowing users to power up their devices without the hassle of cables.

In addition to fast charging, the Galaxy S25 Ultra employs intelligent battery management systems that optimize power consumption. These systems analyze user behavior and adjust settings accordingly to extend battery life. For instance, the device can automatically reduce power usage during periods of inactivity or when certain applications are not in use. This proactive approach not only enhances the overall user experience but also contributes to the longevity of the battery itself, ensuring that it remains effective over time.

While the advancements in battery technology are commendable, it is essential to consider the implications for repairability. As manufacturers prioritize sleek designs and advanced features, the ease of disassembly and repair often takes a backseat. In the case of the Galaxy S25 Ultra, the focus on fast battery solutions has led to a design that may pose challenges for users seeking to replace or repair their batteries independently. The intricate assembly of components, coupled with the use of adhesives, can complicate the disassembly process, making it less accessible for the average consumer.

Moreover, the trend towards non-removable batteries has become more pronounced in recent smartphone models, including the Galaxy S25 Ultra. While this design choice allows for thinner devices and improved water resistance, it also raises concerns regarding sustainability and repairability. Users may find themselves facing difficulties when their batteries begin to degrade, as accessing and replacing these components often requires specialized tools and expertise. Consequently, this situation underscores the need for manufacturers to strike a balance between innovative design and user-friendly repair options.

In conclusion, the Galaxy S25 Ultra showcases remarkable advancements in battery technology, particularly with its fast charging capabilities and intelligent power management systems. These features cater to the needs of modern users who demand efficiency and convenience. However, as the industry continues to prioritize sleek designs and advanced functionalities, the challenges associated with repairability cannot be overlooked. As consumers become increasingly aware of these issues, it is crucial for manufacturers to consider the long-term implications of their design choices, ensuring that users can enjoy both cutting-edge technology and the ability to maintain their devices effectively.

Analyzing Repairability Advances in the Galaxy S25 Ultra

The Galaxy S25 Ultra has garnered significant attention for its impressive specifications and features, but an equally important aspect that consumers often overlook is its repairability. As technology continues to evolve, manufacturers face the challenge of balancing cutting-edge design with user-friendly repair options. In analyzing the repairability advances in the Galaxy S25 Ultra, it becomes evident that while some improvements have been made, there are still considerable limitations that may affect the overall user experience.

One of the most notable advancements in the Galaxy S25 Ultra is its battery solution. The device incorporates a fast battery replacement mechanism that allows users to access the battery with relative ease. This is a significant improvement over previous models, where battery replacement often required specialized tools and expertise. The design of the S25 Ultra facilitates a quicker disassembly process, enabling users or technicians to replace the battery without extensive disassembly of the device. This is particularly beneficial for users who rely heavily on their smartphones and cannot afford prolonged downtime due to battery issues.

However, despite this positive development, the overall repairability of the Galaxy S25 Ultra remains a concern. While the battery can be replaced more efficiently, other components of the device are still challenging to access. For instance, the intricate assembly of the camera modules and the tightly packed internal layout make repairs to these parts more complicated. Users may find that while they can quickly swap out a depleted battery, addressing issues with the camera or screen may require professional assistance, which can be both costly and time-consuming.

Moreover, the materials used in the construction of the Galaxy S25 Ultra also play a role in its repairability. The device features a glass back and a metal frame, which, while aesthetically pleasing, can complicate repairs. Glass components are prone to shattering, and replacing a cracked back cover can be a labor-intensive process. This is in stark contrast to devices that utilize more durable materials, which can withstand wear and tear better and are easier to repair. As a result, while the S25 Ultra may excel in certain areas, its reliance on fragile materials detracts from its overall repairability.

In addition to the physical design, software considerations also impact repairability. The Galaxy S25 Ultra is equipped with advanced software features that enhance user experience but may also complicate repairs. For instance, proprietary software locks and security features can hinder third-party repair services from accessing necessary tools and information. This creates a scenario where users may feel compelled to return to the manufacturer for repairs, further driving up costs and limiting their options.

In conclusion, the Galaxy S25 Ultra presents a mixed bag when it comes to repairability. The fast battery solution is a commendable advancement that addresses a common pain point for users, allowing for quicker resolutions to battery-related issues. However, the complexities involved in repairing other components, coupled with the use of fragile materials and restrictive software practices, highlight the ongoing challenges in achieving a truly repairable device. As consumers become increasingly aware of these issues, it is essential for manufacturers to prioritize not only innovation but also the long-term usability and repairability of their products. This balance will ultimately determine the satisfaction and loyalty of users in an ever-competitive market.

Tools Required for Galaxy S25 Ultra Disassembly

Disassembling the Galaxy S25 Ultra requires a specific set of tools to ensure a smooth and efficient process. As smartphones become increasingly sophisticated, the need for specialized tools has become paramount. To begin with, a precision screwdriver set is essential. This set typically includes various sizes of Phillips and Torx screwdrivers, which are necessary for removing the screws that hold the device together. The Galaxy S25 Ultra, like its predecessors, employs a combination of different screw types, making it crucial to have the right tools on hand to avoid damaging the screws or the device itself.

In addition to screwdrivers, a plastic opening tool is highly recommended. This tool allows for the careful separation of the device’s components without risking damage to the delicate internal parts. Using a plastic tool instead of a metal one minimizes the risk of scratching or denting the phone’s casing, which is particularly important for maintaining the aesthetic integrity of the device. Furthermore, a suction cup can be beneficial for lifting the screen away from the body of the phone. By creating a vacuum seal, the suction cup provides the necessary leverage to gently pry open the device without applying excessive force.

Moreover, tweezers are another indispensable tool for disassembly. They enable the technician to handle small components with precision, ensuring that delicate parts are not dropped or misplaced during the process. The use of tweezers is particularly important when dealing with connectors and cables that are often tightly packed within the device. Additionally, a heat gun or hairdryer can be useful for softening adhesive that holds the screen in place. Applying gentle heat can make it easier to separate the screen from the body, reducing the risk of cracking or damaging the display.

As one prepares for the disassembly of the Galaxy S25 Ultra, it is also wise to have a clean, organized workspace. A magnetic mat or small containers can help keep screws and small components organized, preventing them from getting lost during the process. This organization is crucial, as the complexity of modern smartphones means that even a single misplaced screw can hinder reassembly or lead to functional issues.

While the tools mentioned above are essential for disassembly, it is important to note that the Galaxy S25 Ultra has been designed with certain challenges in mind. The device’s construction incorporates advanced materials and intricate designs, which can complicate the repair process. As a result, while the tools may facilitate disassembly, they do not necessarily guarantee ease of repair. The internal layout of the device, along with the use of adhesives and proprietary components, can pose significant hurdles for those attempting to perform repairs without professional training.

In conclusion, disassembling the Galaxy S25 Ultra requires a careful selection of tools, including precision screwdrivers, plastic opening tools, suction cups, tweezers, and heat sources. While these tools can aid in the disassembly process, the inherent design complexities of the device may still present challenges. As technology continues to evolve, the balance between advanced features and repairability remains a critical consideration for both manufacturers and consumers alike. Understanding the tools required for disassembly is the first step in navigating this intricate landscape, ultimately leading to more informed decisions regarding device maintenance and repair.

Common Issues Encountered During Galaxy S25 Ultra Repairs

The Galaxy S25 Ultra, a flagship device from Samsung, has garnered significant attention for its advanced features and performance. However, like any sophisticated technology, it is not immune to issues that can arise during repairs. Understanding these common problems is essential for both technicians and users who may find themselves needing to address repairs on this device.

One of the most frequently encountered issues during Galaxy S25 Ultra repairs is the complexity of its internal design. The device is engineered with a multitude of components tightly packed into a sleek chassis, which can make accessing certain parts challenging. For instance, the battery, while designed for quick removal in theory, often requires the disassembly of multiple layers of the device. This complexity can lead to increased repair times and the potential for damage to other components if not handled with care.

Moreover, the adhesive used to secure the screen and other components can pose significant challenges. Samsung has employed strong adhesives to ensure the durability and water resistance of the Galaxy S25 Ultra. While this enhances the device’s longevity, it complicates the repair process. Technicians often find themselves needing specialized tools to safely detach the screen without causing cracks or damage to the display. This situation not only prolongs the repair time but also increases the risk of additional costs if the screen is inadvertently damaged during the process.

Another common issue is the availability of replacement parts. As the Galaxy S25 Ultra is a relatively new model, sourcing genuine parts can be difficult. Many repair shops may resort to using third-party components, which can lead to compatibility issues or subpar performance. This situation is particularly concerning for users who prioritize maintaining the integrity and functionality of their devices. The lack of readily available parts can also lead to longer wait times for repairs, which can be frustrating for users who rely heavily on their smartphones for daily tasks.

In addition to these challenges, technicians often encounter software-related issues during repairs. The Galaxy S25 Ultra is equipped with advanced software features that can complicate the repair process. For example, if a technician replaces the battery, they may need to recalibrate the device to ensure that it recognizes the new battery correctly. Failure to do so can result in inaccurate battery readings or performance issues, which can further complicate the repair process.

Furthermore, the device’s intricate security features, such as biometric sensors, can also present challenges. If a technician inadvertently disrupts these systems during a repair, it may lead to additional complications, including the need for software resets or reconfigurations. This not only adds to the time required for repairs but can also create anxiety for users concerned about the security of their personal data.

In conclusion, while the Galaxy S25 Ultra offers impressive technology and performance, its repairability is hindered by several common issues. The complexity of its internal design, the strength of the adhesives used, the availability of replacement parts, and the intricacies of its software and security features all contribute to a challenging repair landscape. As technology continues to evolve, it is crucial for manufacturers to consider these factors to enhance the repairability of their devices, ultimately benefiting both technicians and users alike.

Comparing Galaxy S25 Ultra Repairability to Previous Models

The Galaxy S25 Ultra represents a significant evolution in Samsung’s flagship smartphone lineup, particularly when it comes to its internal design and repairability. As consumers increasingly prioritize sustainability and longevity in their devices, the repairability of smartphones has become a critical factor in purchasing decisions. In comparing the Galaxy S25 Ultra to its predecessors, it becomes evident that while there have been advancements in certain areas, challenges remain, particularly regarding overall repairability.

One of the most notable improvements in the Galaxy S25 Ultra is its battery replacement process. Samsung has streamlined this aspect, allowing for a faster and more efficient battery swap compared to earlier models. This enhancement is particularly beneficial for users who may experience battery degradation over time, as it reduces the time and effort required to replace the battery. In previous iterations, such as the Galaxy S21 Ultra, accessing the battery often involved a more complex disassembly process, which could deter users from attempting repairs themselves or seeking professional help. The S25 Ultra’s design reflects a growing awareness of consumer needs, emphasizing ease of access to critical components.

However, despite this positive development, the overall repairability of the Galaxy S25 Ultra has not seen a corresponding leap forward. While the battery replacement has been simplified, other components remain challenging to access. For instance, the camera modules and display are still tightly integrated into the device, requiring specialized tools and expertise for repairs. This complexity is reminiscent of the Galaxy S22 Ultra, where users faced similar hurdles when attempting to replace or repair essential parts. As a result, while the battery solution has improved, the overall repairability score of the S25 Ultra may not reflect a significant advancement when viewed in the context of the entire device.

Moreover, the materials used in the construction of the Galaxy S25 Ultra also play a role in its repairability. The use of glass and metal, while aesthetically pleasing and providing a premium feel, can complicate repairs. Previous models, such as the Galaxy S20 Ultra, faced criticism for their fragility, and while Samsung has made strides in durability, the inherent nature of these materials still poses challenges for repair technicians. The risk of cracking or damaging components during disassembly remains a concern, which can lead to increased repair costs and longer turnaround times for consumers.

In addition to the physical design, software updates and support for repairs are crucial factors in the overall repairability of a device. Samsung has made efforts to provide better software support for its devices, but the availability of spare parts and repair documentation can vary significantly. This inconsistency can hinder independent repair efforts, as users may find it difficult to source the necessary components or obtain guidance on performing repairs. In this regard, the Galaxy S25 Ultra does not significantly differ from its predecessors, leaving room for improvement in fostering a more repair-friendly ecosystem.

In conclusion, while the Galaxy S25 Ultra showcases advancements in battery replacement efficiency, it also highlights the ongoing challenges in repairability that persist across Samsung’s flagship models. The balance between design aesthetics, material choices, and user-friendly repair options remains delicate. As consumers continue to advocate for more sustainable practices, it is imperative for manufacturers like Samsung to prioritize not only the ease of battery replacement but also the overall accessibility of repairs for all components. This holistic approach will ultimately enhance the longevity and sustainability of their devices, aligning with the evolving expectations of today’s consumers.

Q&A

1. **Q: What is the primary challenge in disassembling the Galaxy S25 Ultra?**

A: The primary challenge is the extensive use of adhesive, which makes it difficult to open the device without damaging components.

2. **Q: How does the battery replacement process compare to previous models?**

A: The battery replacement process is faster due to improved design, but still requires careful handling to avoid damaging other components.

3. **Q: What tools are recommended for disassembling the Galaxy S25 Ultra?**

A: Recommended tools include a heat gun, plastic prying tools, and a suction cup to safely open the device.

4. **Q: Are there any notable improvements in repairability for the Galaxy S25 Ultra?**

A: While there are some improvements, such as modular components, overall repairability remains low due to the use of strong adhesives and complex assembly.

5. **Q: What components are most difficult to access during disassembly?**

A: The camera modules and internal wiring are often the most difficult components to access due to their placement and the need to remove multiple layers.

6. **Q: Is it advisable for average users to attempt disassembly of the Galaxy S25 Ultra?**

A: It is generally not advisable for average users to attempt disassembly due to the risk of damaging the device and the need for specialized tools and skills.The disassembly of the Galaxy S25 Ultra reveals a fast battery replacement solution, highlighting improvements in efficiency for users needing quick battery swaps. However, the overall repairability of the device remains limited, with design choices that complicate repairs and access to internal components. This indicates a growing trend where manufacturers prioritize user convenience for specific tasks while still facing challenges in enhancing overall repairability.