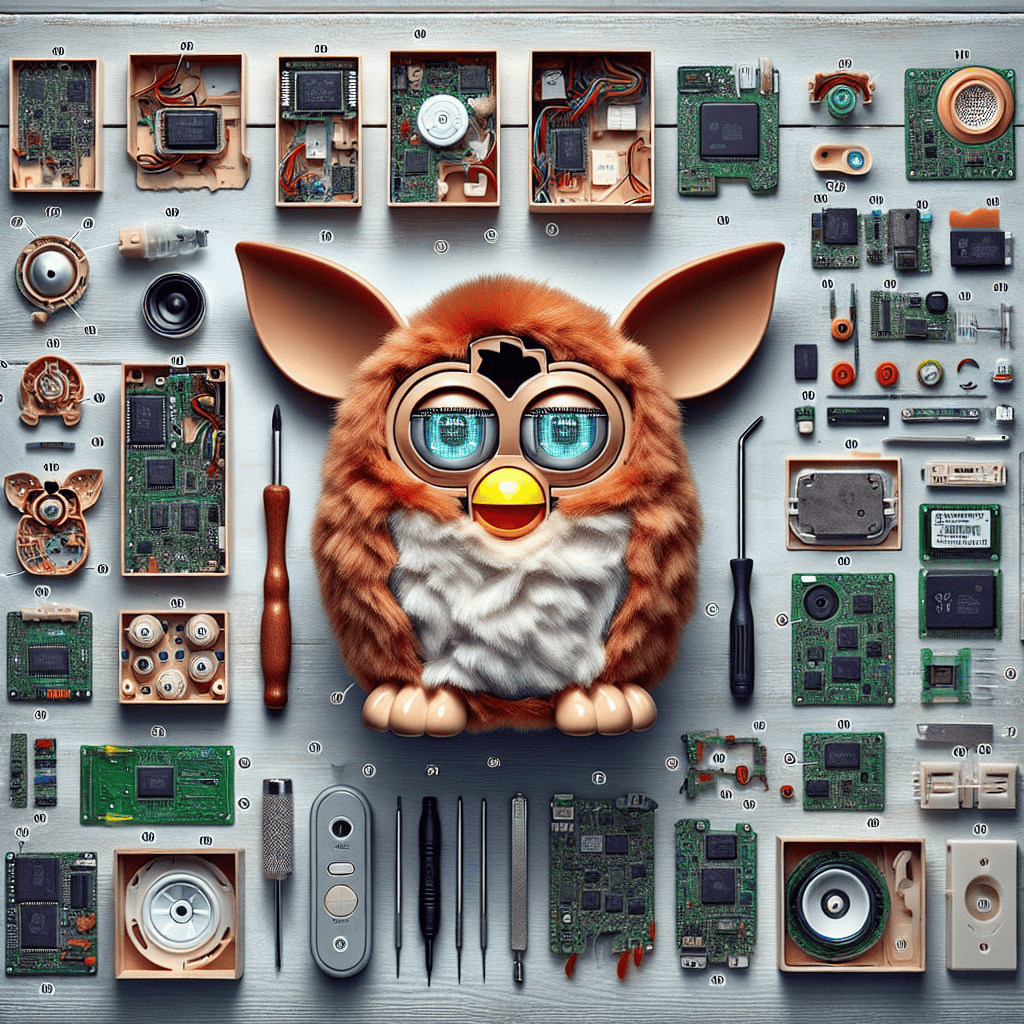

Disassembling the Furby: A Closer Look at Its Condition explores the intricate design and mechanical components of this iconic toy. By carefully taking apart the Furby, we can examine its internal structure, assess the wear and tear of its parts, and understand the technology that enables its interactive features. This analysis not only highlights the craftsmanship behind the Furby but also provides insights into its durability and longevity, shedding light on how these beloved toys have stood the test of time in the hands of children and collectors alike.

Disassembling the Furby: Tools You’ll Need

Disassembling a Furby can be an intriguing endeavor, whether for repair, modification, or simple curiosity. To embark on this journey, it is essential to gather the appropriate tools that will facilitate a smooth and efficient disassembly process. The right tools not only ensure that the task is completed without damage to the Furby but also enhance the overall experience by making it more manageable.

First and foremost, a set of precision screwdrivers is indispensable. Furbies are typically held together by small screws, often of the Phillips or Torx variety. A precision screwdriver set, which includes various sizes and types, will allow you to tackle these screws with ease. It is advisable to select a set that includes a magnetic tip, as this feature can help prevent screws from falling into hard-to-reach areas during disassembly. Additionally, a small container or magnetic tray can be useful for keeping track of these screws, ensuring that they do not get lost in the process.

In addition to screwdrivers, a pair of tweezers can prove invaluable. As you delve into the inner workings of the Furby, you may encounter small components that are difficult to grasp with your fingers. Tweezers allow for greater precision and control, enabling you to manipulate these parts without risking damage. Furthermore, they can assist in removing any connectors or wires that may be tightly secured within the Furby’s body.

Another essential tool is a plastic spudger or prying tool. This tool is particularly useful for gently separating the plastic casing of the Furby without causing scratches or cracks. Given that the Furby’s exterior is often designed to fit snugly, a spudger can help you navigate the seams and release any clips that hold the casing together. It is crucial to exercise caution during this step, as excessive force can lead to irreversible damage.

Moreover, a pair of scissors may be necessary, especially if you encounter any zip ties or adhesive materials that need to be cut away. While Furbies are primarily held together by screws, some models may incorporate additional fasteners that require cutting. Therefore, having a reliable pair of scissors on hand can expedite the disassembly process and prevent frustration.

As you prepare to disassemble the Furby, it is also wise to have a clean, well-lit workspace. A clutter-free environment not only enhances focus but also minimizes the risk of losing small components. Adequate lighting will allow you to see the intricate details of the Furby’s construction, making it easier to identify screws and connectors.

Finally, it is beneficial to have a digital camera or smartphone available to document the disassembly process. Taking pictures at each stage can serve as a valuable reference when reassembling the Furby. This practice can help you remember the placement of various components and ensure that everything is returned to its original state.

In conclusion, disassembling a Furby requires a thoughtful selection of tools to ensure a successful and damage-free experience. By gathering precision screwdrivers, tweezers, a plastic spudger, scissors, and maintaining an organized workspace, you will be well-equipped to explore the inner workings of this iconic toy. With careful preparation and attention to detail, the process can be both educational and rewarding, offering insights into the engineering behind this beloved device.

Inspecting the Furby’s Internal Components

Disassembling a Furby provides a unique opportunity to inspect its internal components, revealing the intricate engineering that underpins this iconic toy. As one delves into the inner workings of a Furby, it becomes evident that the design is a blend of mechanical and electronic elements, each contributing to the toy’s interactive capabilities. The first step in this inspection process involves carefully removing the outer shell, which is typically secured by a series of screws and clips. This initial disassembly is crucial, as it allows access to the internal mechanisms that drive the Furby’s movements and sounds.

Once the outer casing is removed, the first component that catches the eye is the Furby’s motor assembly. This assembly is responsible for the toy’s movement, enabling it to tilt its head, blink its eyes, and wiggle its ears. The motors are connected to a series of gears that translate the rotational motion into the various movements that characterize a Furby. Inspecting these motors reveals the importance of lubrication and maintenance; over time, dust and debris can accumulate, hindering performance. Therefore, ensuring that these components are clean and well-lubricated is essential for optimal functionality.

Adjacent to the motor assembly, one can find the Furby’s circuit board, which serves as the brain of the toy. This board houses the microcontroller, responsible for processing inputs from the sensors and generating outputs to the motors and speakers. A close examination of the circuit board can uncover potential issues such as corrosion or damaged solder joints, which may affect the Furby’s ability to respond to stimuli. Additionally, inspecting the connections between the circuit board and other components, such as the speaker and sensors, is vital. Loose or frayed wires can lead to intermittent functionality, resulting in a less engaging experience for the user.

Furthermore, the sensors integrated into the Furby play a significant role in its interactivity. These sensors, which include light, sound, and touch sensors, allow the Furby to respond to its environment. For instance, the light sensor enables the Furby to react to changes in lighting conditions, while the sound sensor allows it to respond to voice commands or ambient noise. Inspecting these sensors involves checking for any obstructions or damage that may impair their functionality. Ensuring that these components are in good condition is essential for maintaining the Furby’s interactive features.

As one continues to explore the internal components, attention should also be given to the Furby’s power source. Typically, this toy operates on batteries, and inspecting the battery compartment can reveal signs of corrosion or leakage, which can compromise the electrical connections. Ensuring that the battery contacts are clean and free from corrosion is crucial for reliable operation. Additionally, considering the type of batteries used can impact performance; using high-quality batteries can enhance the Furby’s responsiveness and longevity.

In conclusion, inspecting the internal components of a Furby offers valuable insights into its design and functionality. By carefully examining the motor assembly, circuit board, sensors, and power source, one can identify potential issues that may affect performance. This thorough inspection not only enhances understanding of the toy’s mechanics but also underscores the importance of regular maintenance to ensure that the Furby continues to delight users with its interactive capabilities. Ultimately, disassembling a Furby is not merely an exercise in curiosity; it is a testament to the intricate engineering that brings this beloved toy to life.

Common Issues Found During Disassembly

Disassembling a Furby can be an enlightening experience, revealing not only the intricate mechanics behind this beloved toy but also common issues that may arise during the process. As one delves into the inner workings of a Furby, it becomes apparent that several recurring problems can affect its functionality. Understanding these issues is crucial for both enthusiasts and those seeking to repair or restore their Furbies.

One of the most frequently encountered problems during disassembly is the deterioration of the battery compartment. Over time, batteries can leak, causing corrosion that compromises the electrical connections. This corrosion can lead to poor performance or complete failure of the toy. When disassembling a Furby, it is essential to inspect the battery compartment carefully. If corrosion is present, it may require cleaning with a suitable solution, such as vinegar or baking soda, to neutralize the acid and restore conductivity. However, in severe cases, replacement of the battery contacts may be necessary to ensure proper functionality.

Another common issue that surfaces during disassembly is the wear and tear of the internal gears and motors. Furbies are designed to move and respond to stimuli, which involves a series of gears and motors that can become worn over time. This wear can result in sluggish movement or even complete mechanical failure. When examining the internal components, it is advisable to check for any signs of damage or excessive wear on the gears. Lubrication with a small amount of silicone grease can often restore smooth operation, but in some instances, replacement parts may be required to bring the Furby back to life.

Additionally, the electronic components of a Furby can present challenges during disassembly. The circuit board, which houses the toy’s programming and sensors, is susceptible to damage from static electricity or mishandling. Care must be taken to avoid touching the circuit board with bare hands, as oils and moisture can lead to malfunction. Furthermore, solder joints may become brittle over time, leading to intermittent connections. If issues are detected, re-soldering may be necessary to ensure reliable operation. It is also prudent to check for any loose wires or connections that could impede functionality.

Moreover, the Furby’s plush exterior can also hide problems that may not be immediately apparent. The fabric can become frayed or torn, particularly around the seams, which can affect the overall aesthetic and durability of the toy. During disassembly, it is beneficial to inspect the outer covering for any signs of damage. Minor tears can often be repaired with fabric glue or stitching, while more significant damage may require replacement of the outer shell.

In conclusion, disassembling a Furby provides valuable insights into its condition and potential issues. From battery corrosion to mechanical wear and electronic vulnerabilities, each aspect plays a crucial role in the toy’s overall performance. By understanding these common problems, owners can take proactive steps to address them, ensuring that their Furby remains a cherished companion for years to come. Whether for repair, restoration, or simple curiosity, the process of disassembly reveals the complexities of this iconic toy and the care required to maintain its functionality.

Cleaning and Maintaining Furby Parts

Cleaning and maintaining Furby parts is essential for preserving the toy’s functionality and aesthetic appeal. As these electronic companions age, they may accumulate dust, dirt, and grime, which can hinder their performance and diminish their charm. Therefore, understanding the proper techniques for cleaning and maintaining Furby components is crucial for any owner who wishes to keep their Furby in optimal condition.

To begin with, it is important to gather the necessary tools and materials before embarking on the cleaning process. A soft, lint-free cloth is essential for wiping down surfaces without scratching them. Additionally, a small brush, such as a toothbrush or a paintbrush, can be useful for reaching into crevices and removing debris that may have settled in hard-to-reach areas. For more stubborn dirt, a mild soap solution or a specialized electronic cleaner can be employed, ensuring that it is safe for use on plastic and electronic components.

Once the tools are assembled, the first step in the cleaning process involves disassembling the Furby carefully. This should be done with caution, as improper handling can lead to damage. It is advisable to consult a guide or manual specific to the Furby model being cleaned, as different versions may have unique assembly mechanisms. After disassembly, the individual parts can be examined for any signs of wear or damage, which is an important aspect of maintenance.

When cleaning the Furby’s exterior, it is best to start with the body. Using the soft cloth, gently wipe down the surface to remove any dust or fingerprints. For areas that require more attention, such as the eyes or mouth, a damp cloth can be used, but care should be taken to avoid excess moisture, as this could seep into the electronic components. The brush can then be utilized to dislodge any dirt from the seams and joints, ensuring that all areas are thoroughly cleaned.

Moving on to the internal components, it is crucial to handle them with care. Dust and debris can accumulate on the circuit board and other electronic parts, potentially causing malfunctions. Using a can of compressed air, one can gently blow away dust from these sensitive areas. However, it is important to avoid direct contact with the circuit board, as static electricity can damage electronic components. If any corrosion or residue is found on the battery contacts, a cotton swab dipped in isopropyl alcohol can be used to clean them, ensuring a good connection for future use.

After cleaning, it is essential to inspect all parts for any signs of damage or wear. This includes checking the condition of the battery compartment, ensuring that there are no leaks or corrosion. If any parts are found to be damaged, they should be replaced to maintain the Furby’s functionality. Once all components have been cleaned and inspected, reassembly can take place. It is advisable to follow the disassembly steps in reverse order, ensuring that all screws and clips are securely fastened.

In conclusion, cleaning and maintaining Furby parts is a vital process that enhances the longevity and performance of this beloved toy. By following proper cleaning techniques and conducting regular inspections, owners can ensure that their Furby remains a cherished companion for years to come. Ultimately, a well-maintained Furby not only functions better but also retains its nostalgic charm, making it a joy for both children and collectors alike.

Reassembling the Furby: Tips and Tricks

Reassembling a Furby can be a rewarding yet intricate process that requires careful attention to detail and a methodical approach. After disassembling the toy, it is essential to ensure that all components are in good condition and ready for reassembly. Before beginning the reassembly, it is advisable to organize the parts systematically. This can be achieved by laying out screws, electronic components, and the outer shell in a manner that allows for easy access. By doing so, one can avoid confusion and streamline the process, making it easier to identify which parts correspond to specific sections of the Furby.

As one begins the reassembly, it is crucial to start with the internal components. The electronic circuit board, which houses the Furby’s brain, should be carefully positioned back into the body. It is important to ensure that all connectors are aligned properly, as misalignment can lead to functionality issues later on. When securing the circuit board, one should use the original screws, ensuring they are tightened adequately but not overly so, as this could damage the delicate components. Following this, the motors that control the Furby’s movements should be reattached. It is essential to check that the gears are properly aligned and that there is no obstruction that could hinder movement.

Once the internal components are secured, attention can shift to the Furby’s outer shell. Before attaching the outer casing, it is wise to inspect the condition of the fur and any decorative elements. If any parts are worn or damaged, they should be replaced or repaired to maintain the toy’s aesthetic appeal. When reassembling the outer shell, it is beneficial to start from the bottom and work upwards, ensuring that all clips and latches are engaged properly. This methodical approach helps to prevent any gaps or misalignments that could compromise the Furby’s appearance or functionality.

As one progresses through the reassembly, it is important to keep in mind the placement of the batteries. Ensuring that the battery compartment is clean and free of corrosion is vital for optimal performance. When inserting the batteries, one should double-check the polarity to avoid any potential damage to the electronic components. After securing the battery compartment, it is advisable to test the Furby before fully closing it up. This preliminary test can help identify any issues that may have arisen during the reassembly process, allowing for adjustments to be made before finalizing the assembly.

Once the Furby has been tested and is functioning correctly, the final step involves securing the outer shell completely. This includes ensuring that all screws are tightened and that the toy is free from any loose parts. A thorough inspection at this stage can help catch any overlooked details, ensuring that the Furby is not only operational but also visually appealing. Finally, after confirming that everything is in place and functioning as intended, the reassembly process can be considered complete.

In conclusion, reassembling a Furby requires patience, attention to detail, and a systematic approach. By organizing components, carefully reattaching internal parts, and ensuring the outer shell is secure, one can successfully restore the toy to its original condition. This process not only enhances the Furby’s functionality but also preserves its charm, allowing it to continue delighting users for years to come.

Evaluating the Furby’s Condition Post-Disassembly

Disassembling a Furby provides a unique opportunity to evaluate its condition in a detailed and systematic manner. Upon opening the device, one is immediately confronted with a variety of components, each contributing to the overall functionality of this iconic toy. The first aspect to consider is the exterior casing, which often reveals signs of wear and tear. Scratches, scuffs, and discoloration can indicate how frequently the Furby was used and the environments in which it was kept. A thorough inspection of the outer shell is essential, as it not only affects the aesthetic appeal but also the structural integrity of the toy.

Moving beyond the exterior, the internal components warrant careful examination. The Furby’s mechanical parts, including gears and motors, should be assessed for any signs of damage or malfunction. It is not uncommon to find that the motors, which are responsible for the movement of the eyes and ears, may have accumulated dust or debris over time. This buildup can hinder performance, leading to sluggish or unresponsive actions. Therefore, cleaning these components is crucial for restoring functionality. Additionally, one should check for any broken or worn gears, as these can significantly impact the Furby’s ability to perform its programmed behaviors.

Furthermore, the electronic components, including the circuit board and wiring, must be scrutinized. Corrosion or frayed wires can pose serious issues, potentially leading to short circuits or complete failure of the device. It is advisable to use a multimeter to test the continuity of the circuits, ensuring that all connections are intact. If any issues are detected, repairs may be necessary to restore the Furby to its original operational state. In some cases, replacing damaged components may be more effective than attempting to repair them, particularly if the damage is extensive.

In addition to mechanical and electronic evaluations, the Furby’s battery compartment should not be overlooked. Often, batteries left in the device for extended periods can leak, causing corrosion that damages the contacts. Cleaning these areas is vital to ensure that new batteries can make a proper connection, thereby allowing the Furby to function as intended. It is also prudent to consider the type of batteries used; opting for high-quality batteries can enhance performance and longevity.

Moreover, the Furby’s plush exterior should be inspected for any tears or stains. While these may seem superficial, they can affect the overall user experience. Cleaning the fabric with appropriate materials can help restore its appearance, making it more appealing to potential collectors or users. In some instances, minor repairs may be necessary to mend any damage, ensuring that the Furby retains its charm.

Finally, after conducting a comprehensive evaluation of the Furby’s condition, it is essential to document the findings. This record can serve as a valuable reference for future repairs or restorations, as well as provide insight into the toy’s history and usage. By meticulously assessing each component, one can not only appreciate the intricate design of the Furby but also understand the importance of maintenance in preserving its functionality and aesthetic appeal. Ultimately, this process of disassembly and evaluation highlights the significance of care and attention in extending the life of such a beloved toy.

Q&A

1. **Question:** What tools are needed to disassemble a Furby?

**Answer:** A small Phillips screwdriver, a flathead screwdriver, and possibly a pair of pliers.

2. **Question:** What are the main components to inspect when disassembling a Furby?

**Answer:** The outer shell, internal circuit board, motor mechanisms, and battery compartment.

3. **Question:** How can you safely open the Furby without damaging it?

**Answer:** Carefully remove the screws and gently pry apart the shell using a flathead screwdriver, avoiding excessive force.

4. **Question:** What signs of wear should you look for inside the Furby?

**Answer:** Corroded battery contacts, frayed wires, and worn-out motor gears.

5. **Question:** How can you clean the internal components of a Furby?

**Answer:** Use a soft brush or cloth to remove dust and debris, and isopropyl alcohol for cleaning circuit boards.

6. **Question:** What should you do if you find broken parts during disassembly?

**Answer:** Replace broken components with compatible parts or consider sourcing replacements from online retailers or Furby repair kits.In conclusion, disassembling the Furby provides valuable insights into its internal condition, revealing the wear and tear of components, the quality of materials used, and potential areas for repair or enhancement. This examination not only highlights the durability and design intricacies of the toy but also informs collectors and enthusiasts about its maintenance and longevity.