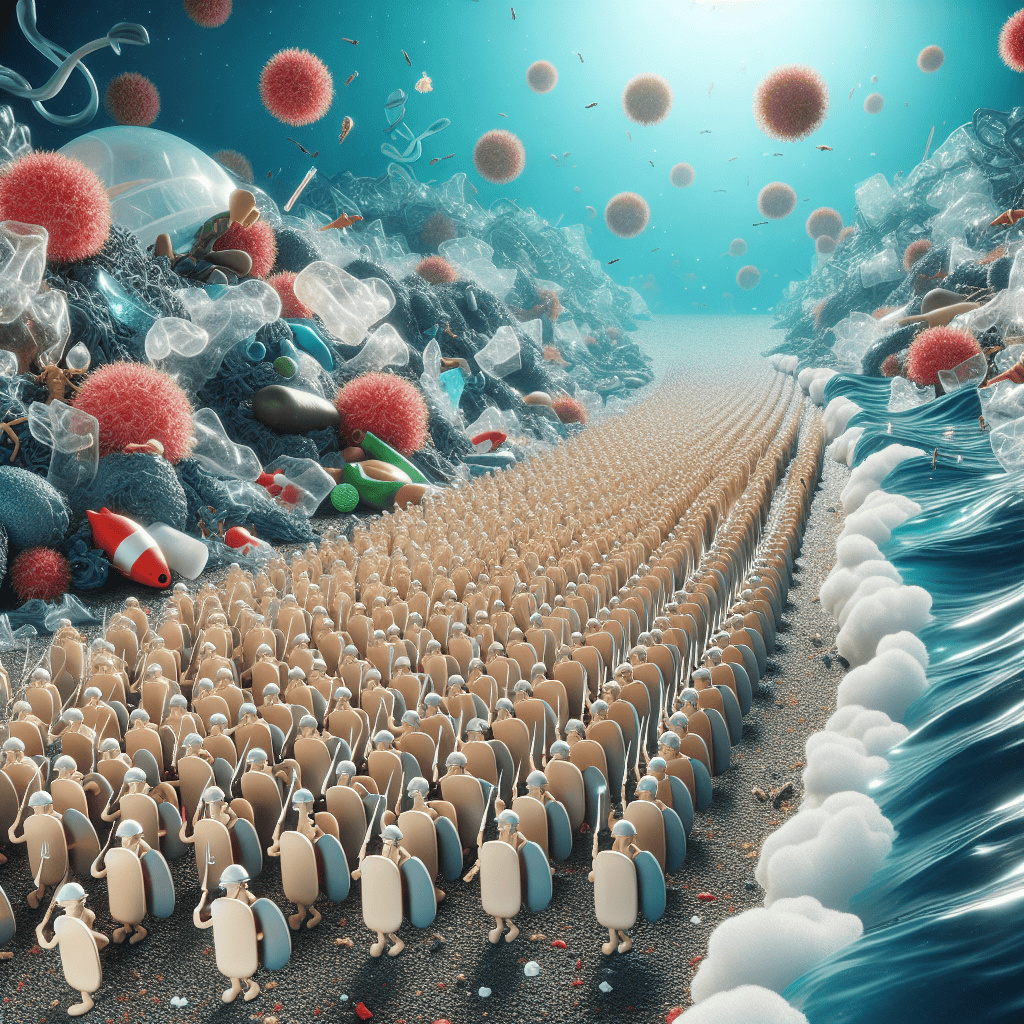

Plastic pollution is a pervasive environmental challenge that threatens ecosystems, wildlife, and human health. As the production and disposal of plastic continue to rise, innovative solutions are urgently needed to mitigate its impact. One promising avenue of research is the development of enzymes capable of breaking down plastic materials. Enzymes, which are biological catalysts, offer a sustainable and efficient approach to degrading plastics into harmless byproducts. By harnessing the power of these natural molecules, scientists aim to accelerate the decomposition process that would otherwise take centuries. Recent advancements in biotechnology and protein engineering have enabled the creation of specialized enzymes that target specific types of plastics, such as polyethylene terephthalate (PET) and polyurethane. These engineered enzymes hold the potential to revolutionize waste management practices, reduce plastic accumulation in landfills and oceans, and pave the way for a circular economy where plastics are continuously recycled and reused. As research progresses, the development of enzymes to combat plastic pollution represents a critical step towards a cleaner and more sustainable future.

Innovative Enzyme Engineering Techniques for Plastic Degradation

Plastic pollution has emerged as one of the most pressing environmental challenges of our time, with millions of tons of plastic waste accumulating in landfills and oceans each year. This persistent problem has spurred scientific communities worldwide to explore innovative solutions, among which enzyme engineering has gained significant attention. Enzymes, being nature’s catalysts, offer a promising avenue for the biodegradation of plastics, particularly polyethylene terephthalate (PET), a common plastic used in bottles and packaging. The development of enzymes capable of breaking down plastic efficiently could revolutionize waste management and significantly reduce environmental pollution.

Recent advancements in enzyme engineering have focused on enhancing the natural ability of certain microorganisms to degrade plastic. Researchers have identified and isolated enzymes such as PETase and MHETase, which are naturally produced by bacteria like Ideonella sakaiensis. These enzymes have shown the ability to break down PET into its constituent monomers, which can then be repurposed to create new plastic products, thus promoting a circular economy. However, the natural efficiency of these enzymes is often insufficient for large-scale applications, necessitating further engineering to improve their performance.

To enhance the efficacy of these enzymes, scientists employ a variety of techniques, including directed evolution and rational design. Directed evolution mimics the process of natural selection in the laboratory, allowing researchers to generate enzyme variants with improved characteristics. By introducing random mutations into the enzyme’s genetic code and selecting for variants with enhanced activity, scientists can evolve enzymes that degrade plastic more rapidly and under a wider range of environmental conditions. This method has already yielded promising results, with some engineered enzymes demonstrating significantly increased degradation rates compared to their natural counterparts.

In parallel, rational design involves the use of computational models to predict how changes in an enzyme’s structure might affect its function. By understanding the three-dimensional structure of an enzyme and the specific interactions that occur during the degradation process, researchers can make targeted modifications to enhance its activity. This approach allows for precise alterations that can improve the enzyme’s stability, substrate affinity, and overall efficiency. The combination of these techniques has led to the development of enzymes that are not only more effective but also more adaptable to different types of plastic waste.

Moreover, the integration of enzyme engineering with other technologies holds great potential for addressing plastic pollution. For instance, coupling engineered enzymes with nanotechnology could facilitate the creation of hybrid materials that enhance the breakdown of plastics in various environments. Additionally, the use of bioreactors equipped with engineered enzymes could enable the large-scale processing of plastic waste, transforming it into valuable raw materials for industrial use.

Despite these advancements, challenges remain in the practical implementation of enzyme-based plastic degradation. Issues such as enzyme stability, cost-effectiveness, and scalability need to be addressed to make this approach viable on a global scale. Continued research and collaboration among scientists, industry stakeholders, and policymakers are essential to overcome these hurdles and harness the full potential of enzyme engineering in combating plastic pollution.

In conclusion, the development of enzymes for plastic degradation represents a promising frontier in the fight against plastic pollution. Through innovative engineering techniques, researchers are making significant strides toward creating efficient, sustainable solutions that could transform how we manage plastic waste. As these technologies continue to evolve, they offer hope for a cleaner, more sustainable future, where plastic pollution is no longer an insurmountable challenge but a manageable problem with viable solutions.

The Role of Enzymes in Breaking Down Microplastics

Plastic pollution has emerged as one of the most pressing environmental challenges of our time, with microplastics posing a particularly insidious threat due to their pervasive presence in ecosystems and potential harm to wildlife and human health. As researchers seek innovative solutions to mitigate this issue, the development of enzymes capable of breaking down microplastics has garnered significant attention. Enzymes, which are biological catalysts that accelerate chemical reactions, offer a promising avenue for addressing the microplastic dilemma due to their specificity and efficiency.

The role of enzymes in breaking down microplastics is rooted in their ability to catalyze the degradation of complex polymers into simpler, non-toxic compounds. This process, known as biodegradation, involves the enzymatic cleavage of the chemical bonds that hold plastic polymers together. By targeting these bonds, enzymes can effectively reduce the size and complexity of plastic particles, ultimately facilitating their assimilation into natural biogeochemical cycles. This enzymatic approach not only offers a potential method for reducing the accumulation of microplastics in the environment but also aligns with the principles of green chemistry by minimizing the use of harsh chemicals and energy-intensive processes.

Recent advancements in biotechnology have accelerated the discovery and engineering of enzymes with enhanced capabilities to degrade microplastics. For instance, researchers have identified several naturally occurring enzymes, such as PETase and MHETase, which exhibit the ability to break down polyethylene terephthalate (PET), a common plastic used in bottles and packaging. Through techniques such as protein engineering and directed evolution, scientists have been able to improve the efficiency and stability of these enzymes, making them more suitable for practical applications in diverse environmental conditions.

Moreover, the integration of enzyme-based solutions into existing waste management systems holds significant potential for scaling up the biodegradation of microplastics. By incorporating enzyme treatments into recycling processes or wastewater treatment facilities, it is possible to enhance the breakdown of microplastics before they enter natural ecosystems. This approach not only addresses the issue at its source but also complements other strategies aimed at reducing plastic waste, such as recycling and the development of biodegradable materials.

Despite the promise of enzyme-based solutions, several challenges remain in their implementation. One of the primary obstacles is the diversity of plastic types and the complexity of their chemical structures, which necessitates the development of a broad range of enzymes tailored to specific polymers. Additionally, the environmental conditions in which these enzymes must operate, such as temperature, pH, and the presence of inhibitors, can significantly impact their effectiveness. Therefore, ongoing research is essential to optimize enzyme performance and ensure their viability in real-world applications.

In conclusion, the development of enzymes to combat plastic pollution represents a promising frontier in environmental biotechnology. By harnessing the catalytic power of enzymes, it is possible to devise sustainable solutions for the degradation of microplastics, thereby mitigating their impact on ecosystems and human health. As research continues to advance in this field, the integration of enzyme-based strategies with existing waste management practices could play a crucial role in addressing the global challenge of plastic pollution. Through continued innovation and collaboration, the potential for enzymes to transform the landscape of plastic waste management becomes increasingly attainable, offering hope for a cleaner and more sustainable future.

Case Studies: Successful Enzyme Applications in Plastic Waste Management

In recent years, the escalating issue of plastic pollution has prompted scientists and environmentalists to seek innovative solutions to mitigate its impact. Among the promising approaches is the development and application of enzymes capable of breaking down plastic waste. These biological catalysts offer a sustainable alternative to traditional methods of plastic disposal, which often involve incineration or landfilling, both of which have significant environmental drawbacks. By harnessing the power of enzymes, researchers aim to transform plastic waste into harmless byproducts, thereby reducing its ecological footprint.

One notable case study in this field involves the discovery and optimization of an enzyme known as PETase, which was originally identified in a bacterium found at a Japanese recycling facility. This enzyme has shown remarkable potential in degrading polyethylene terephthalate (PET), a common plastic used in bottles and packaging. Through genetic engineering and protein engineering techniques, scientists have enhanced the efficiency of PETase, enabling it to break down PET plastics at a much faster rate than previously possible. This advancement not only demonstrates the enzyme’s potential in addressing plastic waste but also highlights the role of biotechnology in environmental conservation.

Transitioning from laboratory success to real-world application, another significant case study is the deployment of enzyme-based solutions in industrial settings. For instance, a collaboration between academia and industry led to the development of a bioreactor system that utilizes engineered enzymes to process plastic waste on a larger scale. This system has been successfully implemented in pilot projects, where it has demonstrated the ability to convert plastic waste into valuable raw materials, such as monomers, which can be reused in the production of new plastics. This circular approach not only reduces the volume of plastic waste but also promotes the concept of a sustainable, closed-loop economy.

Moreover, the versatility of enzyme technology is further exemplified by its application in diverse environmental conditions. In marine environments, where plastic pollution poses a significant threat to aquatic life, researchers have explored the use of enzymes that can function effectively in saline conditions. By isolating and optimizing enzymes from marine microorganisms, scientists have developed solutions that can degrade plastics in oceanic settings, offering a potential remedy for the pervasive issue of marine plastic debris.

Despite these promising developments, challenges remain in the widespread adoption of enzyme-based plastic waste management. One of the primary obstacles is the cost associated with enzyme production and deployment at scale. However, ongoing research is focused on improving the cost-effectiveness of these solutions through advances in synthetic biology and metabolic engineering. By enhancing the production yield and stability of enzymes, researchers aim to make enzyme-based plastic degradation a viable option for large-scale waste management.

In conclusion, the application of enzymes in plastic waste management represents a significant stride towards addressing the global plastic pollution crisis. Through successful case studies, it is evident that enzyme technology holds the potential to revolutionize the way we manage plastic waste, offering an environmentally friendly and sustainable alternative to conventional methods. As research continues to advance, the integration of enzyme-based solutions into existing waste management systems could play a crucial role in mitigating the environmental impact of plastic pollution, paving the way for a cleaner and more sustainable future.

Challenges and Opportunities in Enzyme-Based Plastic Recycling

The global challenge of plastic pollution has reached alarming levels, with millions of tons of plastic waste accumulating in landfills and oceans each year. This environmental crisis has prompted researchers to explore innovative solutions, among which enzyme-based plastic recycling has emerged as a promising avenue. Enzymes, being nature’s catalysts, offer a sustainable approach to breaking down plastics into their constituent monomers, which can then be repurposed into new materials. However, the development and implementation of enzyme-based recycling technologies are fraught with both challenges and opportunities.

To begin with, the primary challenge lies in the diversity and complexity of plastic materials. Plastics such as polyethylene terephthalate (PET), polyethylene (PE), and polypropylene (PP) differ significantly in their chemical structures, necessitating the development of specific enzymes tailored to each type. While some progress has been made, particularly with PET-degrading enzymes like PETase, the efficiency and specificity of these enzymes need substantial enhancement to be viable on an industrial scale. Moreover, the stability of these enzymes under varying environmental conditions poses another hurdle. Enzymes must withstand a range of temperatures and pH levels to be effective in diverse recycling settings, which often requires extensive protein engineering and optimization.

In addition to these technical challenges, economic considerations play a crucial role in the feasibility of enzyme-based recycling. The cost of enzyme production and the scalability of the technology are significant factors that determine its competitiveness with traditional recycling methods. Currently, the production of enzymes at a commercial scale remains expensive, and efforts are underway to reduce these costs through advances in biotechnology, such as the use of microbial fermentation and genetic engineering. Furthermore, integrating enzyme-based processes into existing recycling infrastructures requires substantial investment and adaptation, which can be a deterrent for widespread adoption.

Despite these challenges, the opportunities presented by enzyme-based plastic recycling are substantial. One of the most compelling advantages is the potential for a closed-loop recycling system, where plastics are continuously broken down and reformed without significant loss of material quality. This contrasts with conventional recycling methods, which often result in downcycling, where the quality of the material degrades over time. Enzyme-based recycling could thus contribute to a more sustainable circular economy, reducing the demand for virgin plastic production and minimizing environmental impact.

Moreover, the development of enzyme-based technologies aligns with the growing emphasis on green chemistry and sustainable practices. As public awareness and regulatory pressures increase, industries are incentivized to adopt environmentally friendly solutions. Enzyme-based recycling not only addresses the issue of plastic waste but also reduces the carbon footprint associated with traditional recycling processes, which often involve high energy consumption and the release of greenhouse gases.

In conclusion, while the path to enzyme-based plastic recycling is fraught with challenges, the potential benefits it offers make it a promising area of research and development. Continued advancements in enzyme engineering, coupled with strategic investments and policy support, could pave the way for this innovative technology to become a cornerstone of sustainable waste management. As researchers and industries collaborate to overcome existing barriers, enzyme-based recycling holds the promise of transforming the way we manage plastic waste, contributing to a cleaner and more sustainable future.

Future Prospects of Enzyme Technology in Reducing Plastic Pollution

The burgeoning issue of plastic pollution has become a pressing environmental challenge, prompting scientists and researchers to explore innovative solutions. Among these, the development of enzymes capable of degrading plastic materials presents a promising avenue. Enzymes, which are biological catalysts, have the potential to break down complex polymers found in plastics into simpler, environmentally benign compounds. This approach not only offers a sustainable method for managing plastic waste but also aligns with the principles of green chemistry, which emphasize the reduction of hazardous substances in the environment.

The journey towards utilizing enzymes for plastic degradation began with the discovery of naturally occurring microorganisms that could metabolize certain types of plastics. These microorganisms produce enzymes that can break down the long chains of polymers into smaller, more manageable molecules. Building on this natural phenomenon, scientists have been able to isolate and enhance these enzymes, thereby increasing their efficiency and broadening their applicability to a wider range of plastic types. For instance, the enzyme PETase, derived from a bacterium found in a Japanese recycling plant, has shown remarkable potential in breaking down polyethylene terephthalate (PET), a common plastic used in bottles and textiles.

As research progresses, the focus has shifted towards engineering enzymes with improved capabilities. Through techniques such as protein engineering and directed evolution, scientists are able to modify the structure of enzymes to enhance their stability, activity, and specificity. These advancements have led to the creation of enzymes that can function under a variety of environmental conditions, making them more viable for large-scale applications. Moreover, the integration of computational tools has accelerated the design process, allowing researchers to predict and model enzyme behavior with greater accuracy.

Despite these promising developments, several challenges remain in the path towards widespread adoption of enzyme technology for plastic degradation. One significant hurdle is the economic feasibility of producing and deploying these enzymes on a large scale. The cost of enzyme production must be reduced to make this approach competitive with existing waste management practices. Additionally, the efficiency of enzymes in breaking down plastics must be further improved to ensure that they can handle the vast quantities of plastic waste generated globally.

To address these challenges, interdisciplinary collaboration is essential. Chemists, biologists, and engineers must work together to optimize enzyme production processes and develop innovative delivery systems. Furthermore, partnerships between academia, industry, and government agencies can facilitate the translation of laboratory successes into practical solutions. By fostering such collaborations, the path towards a sustainable future, where enzyme technology plays a pivotal role in mitigating plastic pollution, becomes more attainable.

Looking ahead, the potential impact of enzyme technology on reducing plastic pollution is immense. As research continues to advance, the prospect of integrating enzyme-based solutions into existing waste management systems becomes increasingly feasible. This integration could lead to a significant reduction in the environmental footprint of plastics, contributing to cleaner oceans and healthier ecosystems. Moreover, the development of enzymes tailored to specific types of plastics could revolutionize recycling processes, enabling the recovery and reuse of valuable materials.

In conclusion, while challenges remain, the future prospects of enzyme technology in combating plastic pollution are promising. Continued research and collaboration will be key to overcoming existing barriers and unlocking the full potential of this innovative approach. As society moves towards more sustainable practices, enzyme technology stands out as a beacon of hope in the fight against plastic pollution, offering a path towards a cleaner and more sustainable planet.

Comparing Enzymatic Solutions to Traditional Plastic Degradation Methods

Plastic pollution has emerged as one of the most pressing environmental challenges of our time, prompting scientists and researchers to explore innovative solutions for mitigating its impact. Among these solutions, the development of enzymes specifically designed to degrade plastic has garnered significant attention. To understand the potential of enzymatic solutions, it is essential to compare them with traditional plastic degradation methods, examining their respective advantages and limitations.

Traditional methods of plastic degradation primarily involve mechanical recycling and chemical processes. Mechanical recycling, the most common approach, involves collecting, sorting, and processing plastic waste into new products. While this method is effective for certain types of plastics, it is limited by the quality degradation that occurs with each recycling cycle. Additionally, not all plastics are suitable for mechanical recycling due to contamination or the complexity of their composition. Chemical recycling, on the other hand, breaks down plastics into their monomers or other useful chemicals through processes such as pyrolysis or solvolysis. Although chemical recycling can handle a broader range of plastics, it often requires high energy inputs and can produce hazardous byproducts, raising concerns about its environmental sustainability.

In contrast, enzymatic solutions offer a promising alternative by leveraging the natural ability of enzymes to catalyze the breakdown of complex molecules. Enzymes are biological catalysts that can operate under mild conditions, making them potentially more environmentally friendly than traditional methods. Recent advancements in biotechnology have led to the discovery and engineering of enzymes capable of degrading various types of plastics, including polyethylene terephthalate (PET) and polyurethane. These enzymes work by cleaving the polymer chains into smaller, more manageable molecules, which can then be further processed or mineralized by microorganisms.

One of the primary advantages of enzymatic solutions is their specificity. Enzymes can be tailored to target specific types of plastics, potentially increasing the efficiency of the degradation process. Moreover, enzymatic degradation can occur at ambient temperatures and pressures, reducing the energy requirements compared to chemical recycling. This characteristic not only lowers the carbon footprint of the process but also minimizes the risk of producing harmful byproducts. Furthermore, enzymes can be produced through microbial fermentation, a process that can be scaled up sustainably using renewable resources.

However, despite these advantages, enzymatic solutions are not without their challenges. The rate of enzymatic degradation is often slower than that of traditional methods, which can limit their applicability in large-scale operations. Additionally, the cost of enzyme production and purification remains a significant barrier to widespread adoption. Researchers are actively working to overcome these challenges by engineering more efficient enzymes and developing cost-effective production methods. Advances in protein engineering and synthetic biology hold promise for enhancing enzyme performance and reducing costs, potentially making enzymatic solutions more competitive with traditional methods.

In conclusion, while traditional plastic degradation methods have been the mainstay of waste management strategies, enzymatic solutions offer a compelling alternative with distinct environmental benefits. The specificity, mild operating conditions, and potential for sustainable production make enzymes an attractive option for addressing plastic pollution. As research continues to advance in this field, it is likely that enzymatic solutions will play an increasingly important role in the global effort to combat plastic pollution, complementing existing methods and paving the way for a more sustainable future.

Q&A

1. **What are enzymes and how do they work in breaking down plastics?**

Enzymes are biological catalysts that speed up chemical reactions. In the context of breaking down plastics, specific enzymes can degrade plastic polymers into smaller, harmless molecules by breaking the chemical bonds within the plastic.

2. **Which enzymes are currently being researched for plastic degradation?**

Enzymes such as PETase and MHETase, derived from bacteria like *Ideonella sakaiensis*, are being studied for their ability to break down polyethylene terephthalate (PET) plastics.

3. **What are the challenges in using enzymes for plastic degradation?**

Challenges include the slow rate of degradation, the need for specific conditions (such as temperature and pH), and the potential cost of enzyme production and application on a large scale.

4. **How can enzyme efficiency be improved for plastic degradation?**

Enzyme efficiency can be improved through protein engineering techniques, such as directed evolution, to enhance their stability, activity, and specificity under various environmental conditions.

5. **What are the environmental benefits of using enzymes to degrade plastics?**

Enzymatic degradation of plastics offers a more environmentally friendly alternative to traditional methods, reducing plastic waste and minimizing the release of harmful chemicals into ecosystems.

6. **What is the future potential of enzyme technology in addressing plastic pollution?**

The future potential includes developing more robust and versatile enzymes, integrating them into waste management systems, and potentially using them in combination with other biotechnological solutions to create a circular economy for plastics.Developing enzymes to combat plastic pollution represents a promising and innovative approach to addressing one of the most pressing environmental challenges of our time. Enzymes, as biological catalysts, offer a sustainable and efficient method for breaking down plastics, particularly polyethylene terephthalate (PET), into their constituent monomers, which can then be repurposed or safely degraded. Advances in biotechnology, including protein engineering and directed evolution, have enabled the creation of enzymes with enhanced stability and activity under environmental conditions, making them viable for large-scale applications. The integration of these enzymes into waste management systems could significantly reduce the accumulation of plastic waste in landfills and oceans, thereby mitigating the adverse effects on wildlife and ecosystems. Furthermore, enzyme-based recycling processes have the potential to contribute to a circular economy by facilitating the recovery and reuse of plastic materials. However, challenges remain in terms of optimizing enzyme performance, scalability, and economic feasibility. Continued research and collaboration among scientists, industry stakeholders, and policymakers are essential to overcome these hurdles and fully realize the potential of enzymatic solutions in combating plastic pollution.