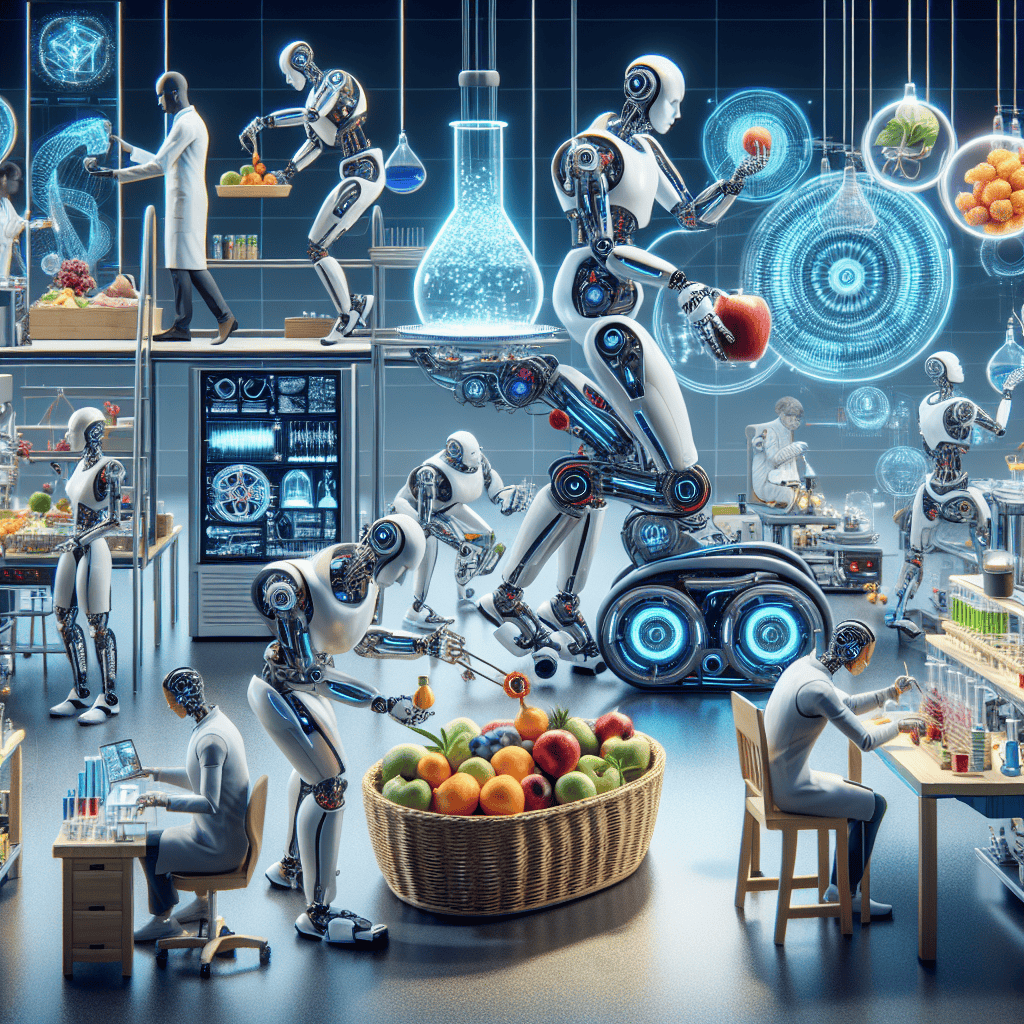

In recent years, the field of robotics has witnessed remarkable advancements, particularly in the realm of robotic dexterity. These breakthroughs are revolutionizing industries by enhancing the precision, adaptability, and efficiency of robotic systems. Our latest innovations in robotic dexterity are pushing the boundaries of what machines can achieve, enabling them to perform complex tasks with a level of finesse and agility that was once thought to be the exclusive domain of human hands. From intricate surgical procedures to delicate assembly lines, these cutting-edge developments are not only transforming the capabilities of robots but also expanding their potential applications across various sectors. As we continue to refine and enhance these technologies, the future of robotics promises to be more dynamic and versatile than ever before, paving the way for a new era of automation and human-robot collaboration.

Enhancing Precision: The Role of AI in Robotic Dexterity

In recent years, the field of robotics has witnessed remarkable advancements, particularly in the realm of robotic dexterity. This progress is largely attributed to the integration of artificial intelligence (AI), which has significantly enhanced the precision and adaptability of robotic systems. As we delve into the intricacies of these innovations, it becomes evident that AI plays a pivotal role in transforming robotic dexterity from a theoretical concept into a practical reality.

To begin with, the incorporation of AI into robotic systems has enabled machines to perform tasks with a level of precision that was previously unattainable. Traditional robotic systems relied heavily on pre-programmed instructions, which limited their ability to adapt to dynamic environments. However, with the advent of AI, robots can now learn from their surroundings and make real-time adjustments. This capability is particularly crucial in industries such as manufacturing and healthcare, where precision is paramount. For instance, in surgical applications, AI-powered robots can execute complex procedures with minimal human intervention, thereby reducing the risk of errors and improving patient outcomes.

Moreover, AI enhances robotic dexterity by enabling machines to process and interpret vast amounts of data. Through machine learning algorithms, robots can analyze patterns and predict outcomes, allowing them to perform tasks with greater accuracy. This data-driven approach is instrumental in refining the fine motor skills of robots, which are essential for tasks that require delicate handling. In the context of assembly lines, for example, AI-driven robots can manipulate small components with exceptional precision, thereby increasing efficiency and reducing waste.

In addition to improving precision, AI also facilitates the development of more versatile robotic systems. By leveraging deep learning techniques, robots can acquire new skills and adapt to a wide range of tasks. This adaptability is crucial in environments that demand flexibility, such as logistics and warehousing. AI enables robots to navigate complex spaces, recognize objects, and make decisions based on real-time data, thereby enhancing their operational efficiency. Consequently, businesses can deploy these intelligent machines across various functions, optimizing their workflows and reducing operational costs.

Furthermore, the integration of AI in robotic systems has led to significant advancements in human-robot collaboration. By equipping robots with sophisticated sensors and AI algorithms, they can better understand and respond to human actions. This capability fosters a more seamless interaction between humans and machines, allowing for collaborative efforts in tasks that require both human intuition and robotic precision. In sectors like automotive manufacturing, this synergy between humans and robots has resulted in improved productivity and safety, as robots can handle repetitive or hazardous tasks while humans focus on more complex problem-solving activities.

As we continue to explore the potential of AI in enhancing robotic dexterity, it is important to acknowledge the challenges that accompany these innovations. Ensuring the ethical use of AI, addressing concerns related to data privacy, and developing robust safety protocols are critical considerations that must be addressed to fully harness the benefits of AI-driven robotic systems. Nevertheless, the progress made thus far underscores the transformative impact of AI on robotic dexterity, paving the way for a future where intelligent machines play an integral role in various aspects of our lives.

In conclusion, the role of AI in enhancing robotic dexterity is both profound and multifaceted. By improving precision, adaptability, and human-robot collaboration, AI has revolutionized the capabilities of robotic systems, making them indispensable tools in numerous industries. As research and development in this field continue to advance, we can anticipate even greater breakthroughs that will further redefine the boundaries of what robots can achieve.

Soft Robotics: Mimicking Human Touch for Delicate Tasks

In recent years, the field of robotics has witnessed remarkable advancements, particularly in the realm of soft robotics, where the focus is on mimicking the human touch to perform delicate tasks. This burgeoning area of research and development is driven by the need for robots that can handle fragile objects with the same care and precision as a human hand. As industries ranging from healthcare to agriculture increasingly rely on automation, the demand for robots capable of performing intricate tasks without causing damage has never been greater.

One of the most significant breakthroughs in soft robotics is the development of materials and structures that closely resemble the flexibility and sensitivity of human skin. These materials, often composed of silicone or other polymers, are designed to deform and adapt to the shape of the objects they interact with. This adaptability is crucial for tasks that require a gentle touch, such as handling fruits and vegetables in agricultural settings or assisting in surgical procedures where precision is paramount. By incorporating sensors that mimic the sensory feedback of human skin, these robots can adjust their grip in real-time, ensuring that they apply just the right amount of pressure.

Moreover, the integration of advanced algorithms and machine learning techniques has further enhanced the capabilities of soft robots. These technologies enable robots to learn from their interactions, improving their performance over time. For instance, by analyzing data from previous tasks, a robot can refine its approach to handling delicate items, reducing the likelihood of damage. This ability to learn and adapt is a significant step forward in achieving robotic dexterity that rivals human capabilities.

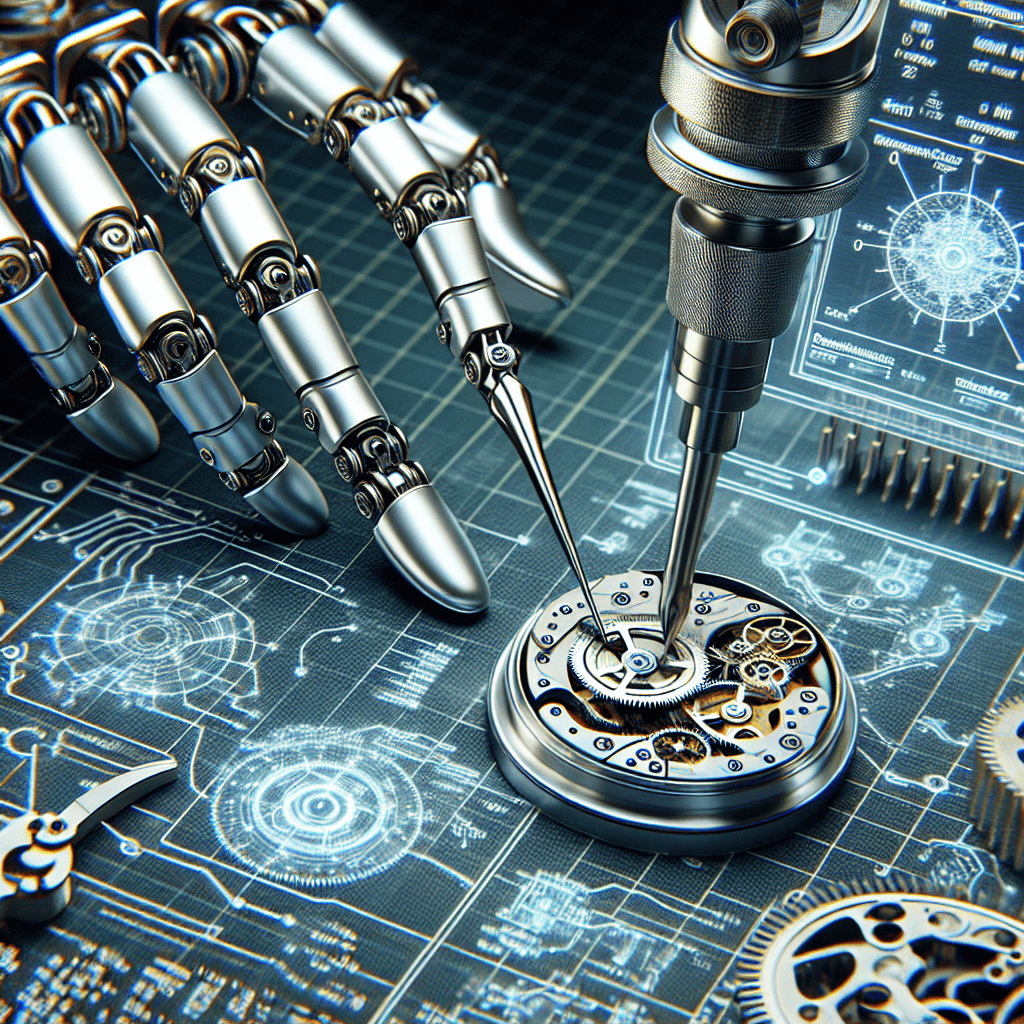

In addition to material and algorithmic innovations, the design of robotic systems has also evolved to better mimic the human hand. Researchers are now focusing on creating robotic grippers that replicate the complex movements of human fingers. These grippers are often equipped with multiple joints and actuators, allowing for a wide range of motion and the ability to perform tasks that require fine motor skills. The combination of flexible materials, sensory feedback, and sophisticated design results in robots that can perform tasks previously thought to be beyond their reach.

The implications of these advancements in soft robotics are far-reaching. In the medical field, for example, robots with enhanced dexterity can assist surgeons in performing minimally invasive procedures, reducing recovery times and improving patient outcomes. In agriculture, robots capable of gently picking ripe fruits can increase efficiency and reduce waste, addressing the growing demand for sustainable farming practices. Furthermore, in manufacturing, soft robots can handle delicate components with precision, leading to higher quality products and reduced production costs.

As we continue to push the boundaries of what robots can achieve, the potential applications for soft robotics are virtually limitless. However, challenges remain, particularly in the areas of energy efficiency and durability. Researchers are actively exploring solutions to these issues, such as developing more efficient power sources and creating materials that can withstand repeated use without degrading. Despite these challenges, the progress made thus far is a testament to the ingenuity and dedication of scientists and engineers working in this field.

In conclusion, the latest innovations in soft robotics represent a significant leap forward in our quest to create machines that can perform delicate tasks with the same dexterity and care as a human hand. As technology continues to evolve, we can expect to see even more sophisticated robots that will transform industries and improve our daily lives. The journey towards achieving robotic dexterity is ongoing, but the strides made thus far offer a glimpse into a future where robots and humans work seamlessly together.

Advanced Sensors: Revolutionizing Robotic Hand-Eye Coordination

In recent years, the field of robotics has witnessed remarkable advancements, particularly in the realm of robotic dexterity. Central to these developments is the integration of advanced sensors, which have revolutionized robotic hand-eye coordination. This innovation has not only enhanced the precision and efficiency of robotic systems but also expanded their applicability across various industries. As we delve into the intricacies of these advancements, it becomes evident that the synergy between sensors and robotics is paving the way for unprecedented capabilities.

To begin with, the role of sensors in robotic systems cannot be overstated. Sensors serve as the primary interface between a robot and its environment, providing critical data that informs decision-making processes. In the context of robotic dexterity, sensors are instrumental in enabling robots to perceive and interpret their surroundings with remarkable accuracy. This is achieved through a combination of visual, tactile, and proprioceptive sensors, each contributing unique insights that collectively enhance a robot’s ability to interact with objects and environments.

Visual sensors, for instance, have undergone significant improvements, allowing robots to process complex visual information with greater speed and precision. High-resolution cameras, coupled with advanced image processing algorithms, enable robots to recognize and track objects in real-time. This capability is crucial for tasks that require precise manipulation, such as assembling intricate components or performing delicate surgical procedures. Moreover, the integration of depth sensors has further augmented visual perception, allowing robots to understand spatial relationships and navigate three-dimensional spaces with ease.

In addition to visual sensors, tactile sensors play a pivotal role in refining robotic dexterity. These sensors mimic the human sense of touch, providing robots with the ability to detect pressure, texture, and temperature. By incorporating tactile feedback, robots can adjust their grip strength and manipulate objects with a level of finesse that was previously unattainable. This advancement is particularly beneficial in applications where delicate handling is essential, such as in the food industry or in the care of fragile artifacts.

Furthermore, proprioceptive sensors contribute to the overall coordination of robotic systems by providing information about the robot’s own movements and position. These sensors enable robots to maintain balance, adjust their posture, and execute complex maneuvers with precision. The integration of proprioceptive feedback is especially valuable in dynamic environments, where robots must adapt to changing conditions and maintain stability while performing tasks.

The convergence of these sensor technologies has led to a new era of robotic hand-eye coordination, characterized by enhanced adaptability and versatility. Robots equipped with advanced sensors can now perform tasks that were once considered exclusive to human capabilities. From intricate surgical procedures to precise industrial assembly, the applications of these innovations are vast and varied. As industries continue to embrace automation, the demand for robots with superior dexterity and coordination is expected to grow exponentially.

In conclusion, the integration of advanced sensors has fundamentally transformed the landscape of robotic dexterity. By enhancing hand-eye coordination, these sensors have enabled robots to perform tasks with unprecedented precision and efficiency. As research and development in this field continue to progress, we can anticipate even greater breakthroughs that will further expand the capabilities of robotic systems. Ultimately, the fusion of sensor technology and robotics holds the promise of revolutionizing industries and improving the quality of life across the globe.

Machine Learning: Teaching Robots to Adapt and Improve

In recent years, the field of robotics has witnessed remarkable advancements, particularly in the realm of robotic dexterity. These breakthroughs are largely attributed to the integration of machine learning techniques, which have significantly enhanced the ability of robots to adapt and improve their performance in dynamic environments. As we delve into the intricacies of these innovations, it becomes evident that machine learning is not merely a tool but a transformative force driving the evolution of robotic capabilities.

At the core of these advancements is the concept of reinforcement learning, a subset of machine learning that enables robots to learn from their interactions with the environment. By employing trial-and-error methods, robots can develop a repertoire of skills that allow them to perform complex tasks with increasing efficiency. This approach mimics the way humans learn, as it involves receiving feedback from actions and using this information to refine future behavior. Consequently, robots are no longer limited to pre-programmed instructions but can adapt to new situations, making them more versatile and effective in real-world applications.

Moreover, the integration of deep learning algorithms has further propelled the development of robotic dexterity. These algorithms enable robots to process vast amounts of data and recognize patterns that are crucial for executing intricate tasks. For instance, in manufacturing settings, robots equipped with deep learning capabilities can identify and manipulate objects of varying shapes and sizes with precision. This level of adaptability is particularly beneficial in industries where customization and flexibility are paramount, as it allows robots to seamlessly transition between different tasks without the need for extensive reprogramming.

In addition to reinforcement and deep learning, the advent of imitation learning has also played a pivotal role in enhancing robotic dexterity. Through this approach, robots learn by observing and mimicking human actions, thereby acquiring skills that are difficult to encode explicitly. This method not only accelerates the learning process but also enables robots to perform tasks that require a high degree of finesse, such as surgical procedures or delicate assembly operations. By leveraging imitation learning, robots can achieve a level of precision and dexterity that was previously unattainable, opening new avenues for their application in various sectors.

Furthermore, the continuous improvement of sensor technology has complemented these machine learning techniques, providing robots with a heightened sense of perception. Advanced sensors allow robots to gather detailed information about their surroundings, which is crucial for making informed decisions and executing tasks with accuracy. This synergy between machine learning and sensor technology has resulted in robots that are not only more dexterous but also more autonomous, capable of operating in unstructured environments with minimal human intervention.

As we look to the future, the potential for further breakthroughs in robotic dexterity is immense. Ongoing research in machine learning is poised to unlock new capabilities, enabling robots to tackle increasingly complex challenges. The integration of artificial intelligence with robotics promises to revolutionize industries ranging from healthcare to logistics, offering solutions that are both efficient and adaptable. In conclusion, the marriage of machine learning and robotics is ushering in a new era of innovation, where robots are not just tools but intelligent partners capable of transforming the way we live and work.

Collaborative Robots: Enhancing Dexterity in Human-Robot Teams

In recent years, the field of robotics has witnessed remarkable advancements, particularly in the realm of collaborative robots, often referred to as cobots. These innovations have significantly enhanced the dexterity of robots, enabling them to work alongside humans more effectively and safely. As industries increasingly integrate these sophisticated machines into their operations, understanding the nuances of robotic dexterity becomes crucial. This article delves into the latest breakthroughs in this area, highlighting how these developments are transforming human-robot collaboration.

To begin with, the concept of robotic dexterity encompasses a robot’s ability to manipulate objects with precision and adaptability, akin to human hand movements. This capability is essential for tasks that require fine motor skills, such as assembling delicate components or handling fragile materials. Recent innovations have focused on improving the mechanical design and control algorithms of robotic hands, thereby enhancing their ability to perform complex tasks. For instance, the integration of soft robotics has led to the development of grippers that can adjust their grip strength and shape to accommodate various objects, mimicking the versatility of a human hand.

Moreover, advancements in sensor technology have played a pivotal role in augmenting robotic dexterity. High-resolution tactile sensors now enable robots to perceive and respond to subtle changes in pressure and texture, allowing for more nuanced interactions with their environment. These sensors, combined with sophisticated machine learning algorithms, empower robots to learn from their experiences and refine their movements over time. Consequently, cobots can now perform tasks with a level of precision and adaptability that was previously unattainable.

In addition to mechanical and sensory improvements, the integration of artificial intelligence has further propelled the capabilities of collaborative robots. AI-driven systems facilitate real-time decision-making, enabling robots to adapt to dynamic environments and collaborate more seamlessly with human counterparts. For example, in manufacturing settings, AI algorithms can analyze data from multiple sensors to optimize a robot’s movements, ensuring efficiency and safety. This synergy between AI and robotics not only enhances dexterity but also fosters a more intuitive and productive partnership between humans and machines.

Furthermore, the development of advanced communication protocols has improved the interaction between humans and robots, making collaboration more fluid and effective. These protocols allow for the exchange of information in real-time, enabling robots to understand and anticipate human actions. As a result, cobots can adjust their operations to complement human efforts, thereby reducing the risk of accidents and increasing overall productivity. This harmonious interaction is particularly beneficial in industries such as healthcare, where precision and reliability are paramount.

As we continue to explore the potential of collaborative robots, it is essential to address the challenges associated with their deployment. Ensuring the safety and reliability of these machines remains a top priority, necessitating rigorous testing and validation processes. Additionally, ethical considerations surrounding the use of AI in robotics must be carefully examined to prevent unintended consequences and ensure that these technologies are used responsibly.

In conclusion, the latest innovations in robotic dexterity are revolutionizing the way humans and robots collaborate. Through advancements in mechanical design, sensor technology, artificial intelligence, and communication protocols, cobots are becoming more adept at performing complex tasks with precision and adaptability. As these technologies continue to evolve, they hold the promise of transforming industries and enhancing the synergy between humans and machines, ultimately leading to a more efficient and harmonious future.

Real-World Applications: Robotic Dexterity in Healthcare and Manufacturing

In recent years, the field of robotics has witnessed remarkable advancements, particularly in the realm of robotic dexterity. These innovations have paved the way for significant improvements in both healthcare and manufacturing, two sectors that stand to benefit immensely from enhanced robotic capabilities. As we delve into the real-world applications of robotic dexterity, it becomes evident that these technological breakthroughs are not only transforming industries but also redefining the boundaries of what robots can achieve.

In the healthcare sector, robotic dexterity has emerged as a game-changer, offering unprecedented precision and control in surgical procedures. Surgeons are now able to perform minimally invasive surgeries with the assistance of robotic systems that mimic the intricate movements of the human hand. This level of precision reduces the risk of human error, minimizes patient recovery time, and enhances overall surgical outcomes. For instance, robotic-assisted surgeries in orthopedics and cardiology have demonstrated significant improvements in accuracy and patient safety. Moreover, the integration of advanced sensors and machine learning algorithms allows these robots to adapt to the dynamic environment of the operating room, further enhancing their utility and effectiveness.

Transitioning to the manufacturing sector, robotic dexterity is revolutionizing production lines by enabling robots to perform complex tasks that were once the sole domain of human workers. The ability of robots to manipulate objects with precision and agility has led to increased efficiency and productivity in manufacturing processes. For example, in the automotive industry, robots equipped with dexterous grippers can assemble intricate components with remarkable speed and accuracy, reducing production time and costs. Additionally, these robots can operate in hazardous environments, mitigating risks to human workers and ensuring a safer workplace.

Furthermore, the development of soft robotics has expanded the scope of robotic dexterity, allowing robots to handle delicate and irregularly shaped objects with ease. This innovation is particularly beneficial in industries such as electronics and food processing, where the handling of fragile components and perishable goods is crucial. By employing soft robotic technologies, manufacturers can achieve higher quality standards and reduce waste, ultimately leading to more sustainable production practices.

As we consider the broader implications of these advancements, it is important to acknowledge the role of artificial intelligence in enhancing robotic dexterity. AI-driven algorithms enable robots to learn from their interactions and improve their performance over time. This capability is essential for adapting to the ever-changing demands of healthcare and manufacturing environments. By leveraging AI, robots can not only execute tasks with greater precision but also anticipate potential challenges and adjust their actions accordingly.

In conclusion, the breakthroughs in robotic dexterity are ushering in a new era of innovation across healthcare and manufacturing. These advancements are not only enhancing the efficiency and effectiveness of existing processes but also opening up new possibilities for future applications. As technology continues to evolve, the potential for robots to perform increasingly complex tasks with human-like dexterity will undoubtedly expand, offering exciting opportunities for growth and development in these critical sectors. The integration of robotic dexterity into real-world applications is a testament to the transformative power of technology and its ability to improve our lives in meaningful ways.

Q&A

1. **What is robotic dexterity?**

Robotic dexterity refers to the ability of robots to manipulate objects with precision and skill, similar to human hands, enabling them to perform complex tasks in various environments.

2. **What are some recent breakthroughs in robotic dexterity?**

Recent breakthroughs include advancements in machine learning algorithms for better object recognition, the development of soft robotics for more adaptable gripping, and improved sensor technologies for enhanced tactile feedback.

3. **How do machine learning algorithms improve robotic dexterity?**

Machine learning algorithms allow robots to learn from experience, improving their ability to recognize and manipulate a wide range of objects by adapting to new situations and refining their movements over time.

4. **What role do soft robotics play in enhancing dexterity?**

Soft robotics use flexible materials that mimic the adaptability of human muscles, allowing robots to handle delicate objects without damaging them and to conform to various shapes for more effective manipulation.

5. **How have sensor technologies advanced robotic dexterity?**

Advanced sensor technologies provide robots with detailed tactile feedback, enabling them to detect texture, pressure, and slippage, which is crucial for precise and controlled manipulation of objects.

6. **What are the potential applications of improved robotic dexterity?**

Improved robotic dexterity can be applied in fields such as manufacturing, healthcare, logistics, and service industries, where robots can perform tasks like assembling intricate components, assisting in surgeries, sorting packages, and providing customer service.Breakthroughs in robotic dexterity have significantly advanced the capabilities of robots, enabling them to perform complex tasks with precision and adaptability. Recent innovations have focused on enhancing the fine motor skills of robotic systems, allowing them to manipulate objects with a level of finesse previously unattainable. These advancements are driven by improvements in sensor technology, machine learning algorithms, and the integration of soft robotics, which together enable robots to better understand and interact with their environments. The development of more sophisticated control systems and the use of tactile feedback have further contributed to these breakthroughs, allowing robots to adjust their grip and movements in real-time. As a result, robots are now capable of performing intricate tasks in various fields, including manufacturing, healthcare, and service industries, with increased efficiency and reliability. These innovations not only expand the potential applications of robotics but also pave the way for more collaborative human-robot interactions, ultimately transforming the landscape of automation and human labor.