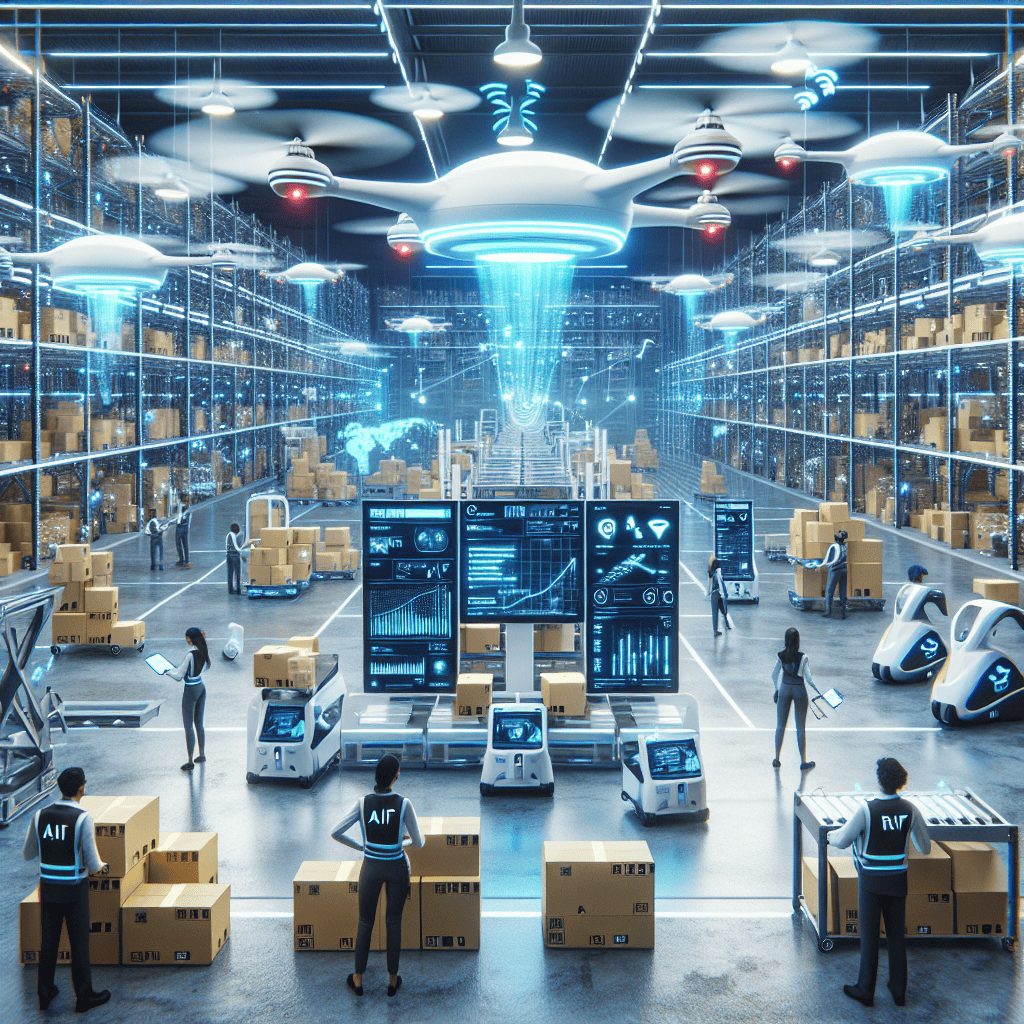

The future of warehousing is being revolutionized by the integration of advanced technologies such as AI, drones, and RFID systems. As e-commerce continues to grow and consumer expectations rise, warehouses are evolving into highly automated and efficient hubs. AI-driven analytics optimize inventory management and streamline operations, while drones enhance inventory tracking and order fulfillment processes. RFID technology provides real-time visibility and accuracy in inventory control, reducing errors and improving overall efficiency. Together, these innovations are transforming traditional warehousing into smart, agile environments capable of meeting the demands of a rapidly changing market.

The Role of AI in Streamlining Warehouse Operations

The integration of artificial intelligence (AI) into warehouse operations is revolutionizing the logistics industry, enhancing efficiency and accuracy in ways previously thought unattainable. As businesses strive to meet the growing demands of e-commerce and global supply chains, AI emerges as a pivotal force in streamlining processes. By leveraging advanced algorithms and machine learning, AI systems can analyze vast amounts of data, enabling warehouses to optimize inventory management, improve order fulfillment, and reduce operational costs.

One of the most significant contributions of AI to warehouse operations is its ability to predict demand with remarkable precision. By analyzing historical sales data, seasonal trends, and market fluctuations, AI can forecast inventory needs, ensuring that warehouses maintain optimal stock levels. This predictive capability not only minimizes the risk of overstocking or stockouts but also enhances the overall responsiveness of the supply chain. Consequently, businesses can better align their inventory with customer demand, leading to improved service levels and increased customer satisfaction.

Moreover, AI-driven automation is transforming the way warehouses operate. Automated guided vehicles (AGVs) and robotic systems, powered by AI, are increasingly being deployed to handle repetitive tasks such as picking, packing, and sorting. These technologies not only reduce the reliance on manual labor but also enhance accuracy and speed. For instance, AI algorithms can optimize the routes taken by AGVs within the warehouse, minimizing travel time and maximizing productivity. As a result, warehouses can process orders more quickly, ultimately leading to faster delivery times and a more agile supply chain.

In addition to improving operational efficiency, AI plays a crucial role in enhancing safety within warehouse environments. By utilizing AI-powered surveillance systems and predictive analytics, warehouses can monitor employee activities and identify potential hazards in real-time. This proactive approach to safety not only helps prevent accidents but also fosters a culture of safety awareness among employees. Furthermore, AI can assist in training programs by analyzing employee performance and providing personalized feedback, ensuring that workers are well-equipped to navigate the complexities of modern warehouse operations.

Transitioning from traditional methods to AI-driven solutions also facilitates better decision-making. With access to real-time data and insights, warehouse managers can make informed choices regarding inventory levels, staffing requirements, and resource allocation. This data-driven approach minimizes guesswork and allows for more strategic planning, ultimately leading to improved operational outcomes. Additionally, AI can identify inefficiencies within existing processes, providing actionable recommendations for continuous improvement.

As the landscape of warehousing continues to evolve, the synergy between AI and other emerging technologies, such as RFID and drones, further amplifies the benefits of automation. For instance, AI can enhance the capabilities of RFID systems by analyzing the data collected from tagged items, enabling real-time tracking and inventory management. Similarly, when integrated with drone technology, AI can facilitate aerial inventory audits, significantly reducing the time and labor required for stocktaking.

In conclusion, the role of AI in streamlining warehouse operations is multifaceted and transformative. By enhancing demand forecasting, automating processes, improving safety, and enabling data-driven decision-making, AI is setting new standards for efficiency and effectiveness in the logistics sector. As businesses continue to embrace these innovations, the future of warehousing promises to be characterized by increased agility, reduced costs, and heightened customer satisfaction, ultimately reshaping the way goods are stored and distributed across the globe.

How Drones Are Revolutionizing Inventory Management

The advent of drones in the realm of inventory management marks a significant shift in how warehouses operate, enhancing efficiency and accuracy in ways previously thought unattainable. As businesses increasingly seek to optimize their supply chain processes, the integration of drone technology into warehousing operations has emerged as a game-changer. Drones, equipped with advanced sensors and imaging capabilities, are capable of conducting inventory checks with remarkable speed and precision. This capability not only reduces the time required for stocktaking but also minimizes human error, which has traditionally plagued manual inventory management.

Moreover, the use of drones allows for real-time data collection, enabling warehouse managers to maintain an up-to-date understanding of stock levels. This immediacy is crucial in today’s fast-paced market, where demand can fluctuate rapidly. By employing drones to perform regular inventory audits, businesses can ensure that they are not overstocked or understocked, thus optimizing their inventory turnover rates. Consequently, this leads to improved cash flow and reduced holding costs, which are vital for maintaining a competitive edge in the industry.

In addition to enhancing accuracy and efficiency, drones also facilitate improved safety within warehouse environments. Traditional inventory management often requires employees to navigate through aisles and climb ladders to access high shelves, which can pose significant safety risks. Drones eliminate the need for such hazardous activities by performing aerial scans and inspections, thereby reducing the likelihood of workplace accidents. This shift not only protects employees but also fosters a culture of safety that can enhance overall morale and productivity.

Furthermore, the integration of drones into inventory management systems can be seamlessly combined with other technologies, such as RFID (Radio Frequency Identification). RFID tags, which can be attached to products and pallets, provide a unique identifier that drones can read as they fly through the warehouse. This synergy between drones and RFID technology allows for even greater accuracy in tracking inventory. As drones scan the warehouse, they can instantly update inventory records, ensuring that data is consistently synchronized across the system. This real-time visibility into inventory levels empowers businesses to make informed decisions regarding restocking and order fulfillment.

As the technology continues to evolve, the potential applications of drones in inventory management are expanding. For instance, advancements in artificial intelligence are enabling drones to not only collect data but also analyze it. This capability allows for predictive analytics, where businesses can forecast inventory needs based on historical data and trends. By anticipating demand, companies can streamline their operations further, reducing waste and improving customer satisfaction through timely deliveries.

In conclusion, the revolution brought about by drones in inventory management is profound and multifaceted. By enhancing accuracy, improving safety, and integrating seamlessly with RFID technology, drones are transforming warehouse operations into more efficient and responsive systems. As businesses continue to embrace these innovations, the future of warehousing looks increasingly promising, characterized by heightened efficiency and a greater ability to meet the demands of an ever-evolving marketplace. The ongoing advancements in drone technology will undoubtedly play a pivotal role in shaping the logistics landscape, making it imperative for companies to adapt and leverage these tools to remain competitive.

The Impact of RFID Technology on Supply Chain Efficiency

The impact of RFID technology on supply chain efficiency is profound, reshaping how businesses manage inventory and streamline operations. Radio Frequency Identification (RFID) technology utilizes electromagnetic fields to automatically identify and track tags attached to objects, which can significantly enhance the accuracy and speed of inventory management. As companies increasingly adopt RFID systems, they are witnessing a transformation in their supply chain processes, leading to improved efficiency and reduced operational costs.

One of the most significant advantages of RFID technology is its ability to provide real-time visibility into inventory levels. Traditional inventory management methods often rely on manual counting and barcode scanning, which can be time-consuming and prone to human error. In contrast, RFID systems allow for the automatic tracking of items as they move through the supply chain. This capability not only minimizes the risk of inaccuracies but also enables businesses to maintain optimal stock levels, reducing the likelihood of overstocking or stockouts. Consequently, companies can respond more swiftly to market demands, ensuring that they meet customer expectations without incurring unnecessary costs.

Moreover, RFID technology enhances the efficiency of warehouse operations. With RFID tags affixed to products, warehouse staff can quickly locate items without the need for extensive searching. This streamlined process reduces the time spent on picking and packing orders, allowing for faster fulfillment and improved customer satisfaction. Additionally, the integration of RFID with automated systems, such as conveyor belts and robotic pickers, further accelerates the movement of goods within the warehouse. As a result, businesses can achieve higher throughput rates, ultimately leading to increased profitability.

In addition to improving inventory management and warehouse operations, RFID technology also plays a crucial role in enhancing supply chain visibility. By providing detailed information about the location and status of products at every stage of the supply chain, RFID enables companies to monitor their operations more effectively. This visibility allows for better decision-making, as businesses can identify bottlenecks and inefficiencies in real time. Furthermore, enhanced visibility fosters collaboration among supply chain partners, as all stakeholders can access accurate data regarding inventory levels and shipment statuses. This collaborative approach not only improves communication but also strengthens relationships between suppliers, manufacturers, and retailers.

Another noteworthy impact of RFID technology is its contribution to reducing losses and theft. With traditional inventory management systems, discrepancies between recorded and actual inventory levels can lead to significant financial losses. However, RFID technology provides a more reliable method of tracking assets, making it easier to identify discrepancies and take corrective action. By minimizing losses due to theft or misplacement, companies can protect their bottom line and ensure that they are operating at peak efficiency.

Furthermore, the implementation of RFID technology can lead to sustainability benefits within the supply chain. By optimizing inventory levels and reducing waste, businesses can minimize their environmental impact. For instance, with better inventory management, companies can avoid overproduction and excess stock, which often ends up in landfills. Additionally, the increased efficiency of operations can lead to reduced energy consumption and lower carbon emissions, aligning with the growing emphasis on corporate social responsibility.

In conclusion, the impact of RFID technology on supply chain efficiency is transformative, offering businesses a multitude of benefits that enhance their operations. From real-time inventory visibility to improved warehouse efficiency and reduced losses, RFID technology is paving the way for a more streamlined and sustainable supply chain. As companies continue to embrace this innovative technology, they are not only improving their operational efficiency but also positioning themselves for success in an increasingly competitive marketplace.

Integrating AI and Drones for Enhanced Warehouse Safety

The integration of artificial intelligence (AI) and drone technology in warehouse operations is revolutionizing the landscape of logistics and supply chain management, particularly in enhancing safety protocols. As warehouses become increasingly complex environments, the need for innovative solutions to mitigate risks and ensure the well-being of personnel has never been more critical. By harnessing the capabilities of AI and drones, organizations can create safer workspaces while simultaneously improving operational efficiency.

To begin with, AI-driven drones are equipped with advanced sensors and imaging technology that allow them to conduct real-time inspections of warehouse facilities. This capability is particularly beneficial for identifying potential hazards, such as structural weaknesses, equipment malfunctions, or unsafe working conditions. By utilizing drones for these inspections, companies can significantly reduce the need for human workers to perform potentially dangerous tasks, such as climbing ladders or navigating hazardous areas. Consequently, this not only minimizes the risk of accidents but also enhances the overall safety culture within the organization.

Moreover, the integration of AI algorithms enables drones to analyze data collected during inspections, providing actionable insights that can inform safety protocols. For instance, AI can identify patterns in equipment wear and tear, allowing for predictive maintenance schedules that prevent equipment failures before they occur. This proactive approach not only safeguards employees but also ensures that operations remain uninterrupted, thereby enhancing productivity. Furthermore, the ability to monitor environmental conditions, such as temperature and humidity, through drone technology can help maintain optimal storage conditions for sensitive goods, further reducing the risk of spoilage or damage.

In addition to inspections, AI drones can assist in monitoring employee movements within the warehouse. By employing computer vision and machine learning techniques, these drones can track personnel in real-time, ensuring that workers are adhering to safety protocols and maintaining safe distances from hazardous areas. This capability is particularly valuable in large warehouses where visibility may be limited. By providing supervisors with real-time data on employee locations and activities, organizations can respond swiftly to any safety concerns, thereby fostering a safer working environment.

Furthermore, the integration of AI and drones can enhance emergency response protocols. In the event of an incident, drones can be deployed to assess the situation quickly, providing first responders with critical information about the nature and extent of the emergency. This rapid assessment can significantly reduce response times, ultimately saving lives and minimizing damage. Additionally, AI can analyze historical incident data to identify trends and develop more effective emergency response strategies, further bolstering warehouse safety.

As the adoption of AI and drone technology continues to grow, it is essential for organizations to invest in training programs that equip employees with the skills necessary to work alongside these advanced systems. By fostering a culture of collaboration between human workers and technology, companies can maximize the benefits of these innovations while ensuring that safety remains a top priority.

In conclusion, the integration of AI and drones in warehouse operations is not merely a trend but a transformative shift that enhances safety and operational efficiency. By leveraging these technologies, organizations can create safer work environments, reduce the risk of accidents, and improve overall productivity. As the future of warehousing unfolds, the continued evolution of AI and drone technology will undoubtedly play a pivotal role in shaping safer and more efficient logistics operations.

Future Trends in Warehouse Automation and Robotics

As the landscape of warehousing continues to evolve, the integration of advanced technologies such as artificial intelligence (AI), drones, and radio-frequency identification (RFID) is poised to redefine operational efficiency and productivity. The future of warehouse automation and robotics is not merely a trend; it represents a fundamental shift in how goods are stored, managed, and distributed. This transformation is driven by the need for greater efficiency, accuracy, and responsiveness in an increasingly competitive market.

One of the most significant trends in warehouse automation is the adoption of AI-driven systems. These systems are capable of analyzing vast amounts of data in real-time, allowing for more informed decision-making. For instance, AI can optimize inventory management by predicting demand patterns and adjusting stock levels accordingly. This predictive capability minimizes the risk of overstocking or stockouts, ultimately leading to cost savings and improved customer satisfaction. Furthermore, AI algorithms can enhance the routing of goods within the warehouse, ensuring that items are stored and retrieved in the most efficient manner possible. As a result, the overall throughput of the warehouse can be significantly increased.

In conjunction with AI, the use of drones in warehouse operations is gaining traction. Drones equipped with advanced sensors and cameras can perform inventory checks with remarkable speed and accuracy. Traditionally, inventory audits are labor-intensive and time-consuming, often requiring workers to manually count items on shelves. However, drones can autonomously navigate through the warehouse, scanning barcodes or RFID tags to provide real-time inventory data. This not only reduces the time spent on audits but also minimizes human error, leading to more accurate inventory records. As drone technology continues to advance, we can expect to see even more sophisticated applications, such as automated picking and packing processes.

Moreover, RFID technology is revolutionizing the way warehouses track and manage inventory. Unlike traditional barcode systems, RFID tags can be read from a distance and do not require line-of-sight, allowing for faster and more efficient scanning. This capability is particularly beneficial in large warehouses where items are stored in various locations. By implementing RFID systems, warehouses can achieve greater visibility into their inventory, enabling them to respond more swiftly to changes in demand. Additionally, RFID technology can enhance security by providing real-time tracking of goods, reducing the risk of theft or loss.

As these technologies continue to mature, we can anticipate a future where human workers and machines collaborate seamlessly. The role of warehouse employees will evolve from manual labor to more strategic positions that require oversight and management of automated systems. This shift not only enhances job satisfaction but also allows workers to focus on higher-value tasks that require critical thinking and problem-solving skills. Training programs will be essential to equip the workforce with the necessary skills to thrive in this new environment.

In conclusion, the future of warehousing is being shaped by the convergence of AI, drones, and RFID technology. These innovations are not only streamlining operations but also paving the way for a more agile and responsive supply chain. As businesses continue to embrace these advancements, they will be better positioned to meet the demands of a rapidly changing market. The integration of these technologies promises to enhance efficiency, accuracy, and overall operational effectiveness, ultimately transforming the warehousing landscape for years to come.

Cost Savings and ROI: The Benefits of AI and RFID in Warehousing

The integration of artificial intelligence (AI) and radio-frequency identification (RFID) technology in warehousing operations is not merely a trend; it represents a significant shift towards more efficient and cost-effective practices. As businesses increasingly seek to optimize their supply chains, the financial implications of adopting these advanced technologies become increasingly apparent. One of the most compelling benefits of AI and RFID in warehousing is the potential for substantial cost savings, which can lead to a favorable return on investment (ROI).

To begin with, AI-driven systems enhance inventory management by providing real-time data analytics. This capability allows warehouse managers to make informed decisions regarding stock levels, order fulfillment, and demand forecasting. By accurately predicting inventory needs, businesses can reduce excess stock and minimize holding costs. Consequently, this leads to a decrease in waste and obsolescence, which are significant financial burdens for many organizations. Moreover, the ability to track inventory in real-time through RFID technology further streamlines operations, as it eliminates the need for manual counting and reduces the likelihood of human error. This efficiency not only saves time but also translates into labor cost reductions, as fewer personnel are required for inventory management tasks.

In addition to labor savings, the implementation of AI and RFID technologies can significantly enhance operational efficiency. For instance, AI algorithms can optimize warehouse layouts and workflows, ensuring that products are stored and retrieved in the most efficient manner possible. This optimization minimizes travel time for workers and automated systems alike, leading to faster order processing and improved customer satisfaction. As a result, businesses can handle a higher volume of orders without the need for proportional increases in labor or space, thereby maximizing their existing resources and driving down operational costs.

Furthermore, the predictive capabilities of AI extend beyond inventory management to encompass maintenance and equipment management. By analyzing data from various sources, AI can forecast when equipment is likely to fail or require maintenance. This proactive approach reduces downtime and extends the lifespan of critical machinery, ultimately leading to lower maintenance costs and increased productivity. The financial benefits of such predictive maintenance are significant, as they allow businesses to allocate resources more effectively and avoid costly disruptions in operations.

Moreover, the synergy between AI and RFID technology fosters enhanced security and loss prevention. RFID systems provide accurate tracking of goods throughout the supply chain, reducing the risk of theft and loss. By minimizing these losses, businesses can protect their bottom line and improve their overall profitability. Additionally, the data collected through RFID systems can be analyzed to identify patterns and trends related to inventory shrinkage, enabling companies to implement targeted strategies to mitigate these issues.

In conclusion, the adoption of AI and RFID technology in warehousing operations offers a multitude of financial benefits that contribute to cost savings and improved ROI. By enhancing inventory management, optimizing workflows, and enabling predictive maintenance, these technologies empower businesses to operate more efficiently and effectively. As the warehousing landscape continues to evolve, organizations that embrace these innovations will not only reduce operational costs but also position themselves for long-term success in an increasingly competitive market. The future of warehousing is undoubtedly intertwined with the advancements in AI and RFID, paving the way for a more streamlined and profitable industry.

Q&A

1. **Question:** How are AI drones being utilized in warehousing operations?

**Answer:** AI drones are used for inventory management, conducting automated stock counts, and monitoring warehouse conditions, which increases efficiency and accuracy.

2. **Question:** What role does RFID technology play in modern warehousing?

**Answer:** RFID technology enables real-time tracking of inventory, reduces manual errors, and streamlines the supply chain by providing accurate data on stock levels and locations.

3. **Question:** How do AI drones improve safety in warehouses?

**Answer:** AI drones can perform hazardous tasks such as inspecting high shelves or monitoring equipment, reducing the risk of accidents for human workers.

4. **Question:** What are the cost benefits of integrating AI drones and RFID technology in warehousing?

**Answer:** The integration can lead to reduced labor costs, lower inventory holding costs, and improved operational efficiency, ultimately resulting in higher profit margins.

5. **Question:** How does the combination of AI drones and RFID technology enhance inventory accuracy?

**Answer:** The combination allows for continuous, automated inventory checks, minimizing discrepancies between recorded and actual stock levels, leading to better decision-making.

6. **Question:** What future trends can be expected in warehousing with the advancement of AI and RFID technologies?

**Answer:** Future trends may include fully automated warehouses, enhanced predictive analytics for inventory management, and increased use of robotics for picking and packing processes.The future of warehousing is being significantly transformed by the integration of AI, drones, and RFID technology, leading to enhanced efficiency, accuracy, and cost-effectiveness. These advancements streamline inventory management, optimize space utilization, and improve order fulfillment processes. As these technologies continue to evolve, they will enable warehouses to operate with greater agility and responsiveness, ultimately reshaping the logistics landscape and setting new standards for operational excellence.