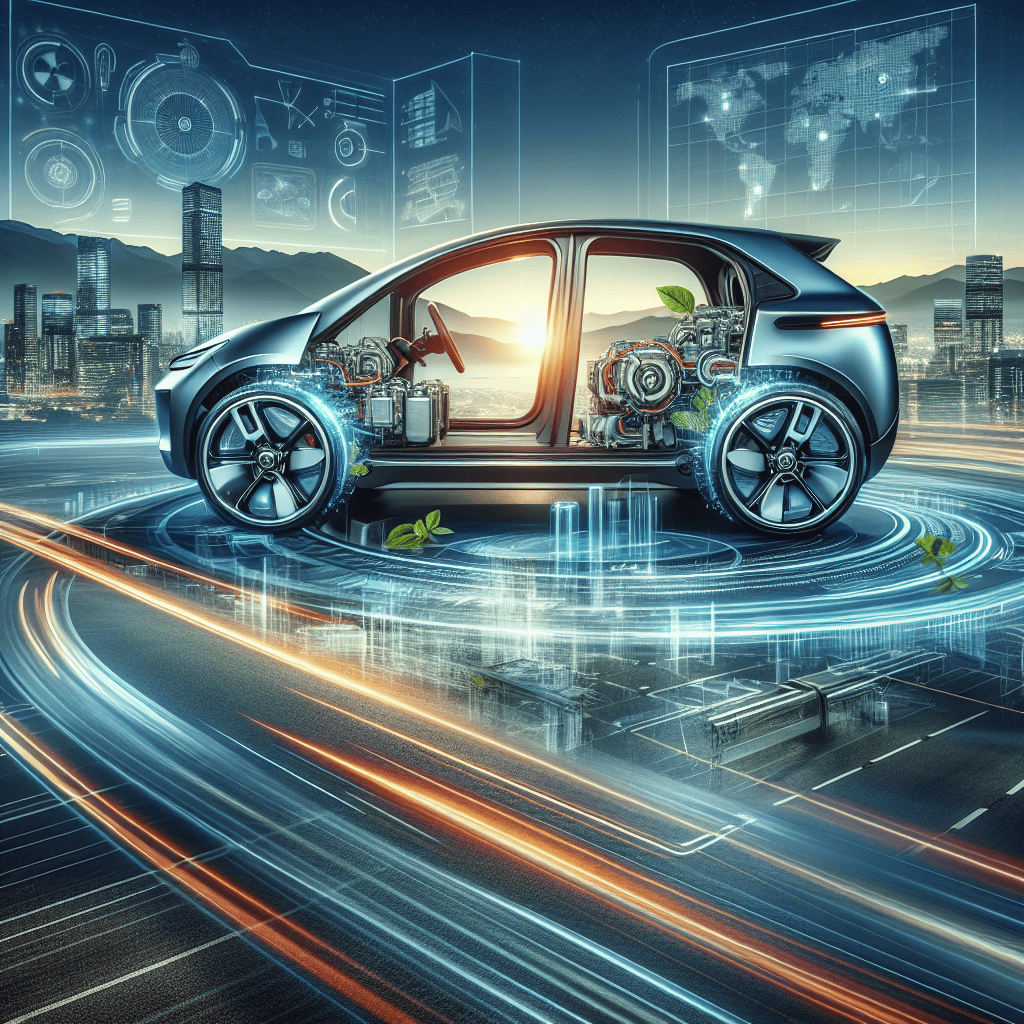

The automotive industry is undergoing a transformative shift with the rise of electric vehicles (EVs), and one of the most promising advancements driving this change is the development of advanced in-wheel motors. These innovative propulsion systems integrate the motor directly into the wheel hub, offering significant benefits in terms of efficiency, weight reduction, and space optimization. By eliminating the need for traditional drivetrain components, in-wheel motors enable manufacturers to design lighter, more compact vehicles that can deliver high performance at a lower cost. This revolution not only enhances the driving experience with improved acceleration and handling but also paves the way for more affordable EV options, making sustainable transportation accessible to a broader audience. As the technology matures, the impact of in-wheel motors on the EV market could redefine performance standards and accelerate the transition to electric mobility.

In-Wheel Motors: A Game Changer for Electric Vehicle Performance

The automotive industry is undergoing a significant transformation, particularly with the rise of electric vehicles (EVs). Among the various innovations driving this change, in-wheel motors have emerged as a pivotal technology that promises to enhance the performance and affordability of electric vehicles. By integrating the motor directly into the wheel hub, this design eliminates the need for traditional drivetrain components, such as axles and differentials, which not only reduces weight but also optimizes space within the vehicle. This innovative approach allows for a more efficient use of energy, ultimately leading to improved performance metrics such as acceleration and handling.

One of the most compelling advantages of in-wheel motors is their ability to provide precise torque control at each wheel. This capability enables advanced traction control and stability systems, which can significantly enhance the driving experience. For instance, in-wheel motors can independently adjust the power delivered to each wheel, allowing for better cornering performance and improved grip on various road surfaces. As a result, vehicles equipped with this technology can achieve superior handling characteristics, making them not only more enjoyable to drive but also safer in challenging conditions.

Moreover, the compact nature of in-wheel motors contributes to a more flexible vehicle design. By freeing up space traditionally occupied by the drivetrain, manufacturers can explore new configurations that enhance aerodynamics and reduce drag. This design flexibility can lead to lighter vehicles that require less energy to operate, thereby extending the range of electric vehicles. As range anxiety remains a significant concern for potential EV buyers, the ability to increase efficiency through innovative design is crucial for the widespread adoption of electric mobility.

In addition to performance benefits, in-wheel motors can also play a vital role in reducing manufacturing costs. The simplification of the drivetrain not only lowers production complexity but also minimizes the number of components required. This reduction can lead to significant cost savings, which can be passed on to consumers, making high-performance electric vehicles more accessible to a broader audience. As the market for electric vehicles continues to expand, affordability will be a key factor in attracting new customers, and in-wheel motors could be instrumental in achieving this goal.

Furthermore, the integration of in-wheel motors aligns with the growing trend of electrification in various vehicle segments, including commercial and public transportation. Buses and delivery vehicles, for example, can benefit from the enhanced maneuverability and efficiency offered by this technology. By adopting in-wheel motors, fleet operators can reduce operational costs while simultaneously contributing to sustainability goals through lower emissions and improved energy efficiency.

As the automotive landscape evolves, the potential of in-wheel motors to revolutionize electric vehicle performance cannot be overstated. With their ability to enhance handling, improve energy efficiency, and reduce manufacturing costs, these motors represent a significant leap forward in EV technology. As manufacturers continue to explore and refine this innovative approach, it is likely that we will see a new generation of electric vehicles that not only meet but exceed the performance expectations of consumers. In this context, in-wheel motors stand out as a game changer, paving the way for a future where high-performance electric vehicles are not just a luxury but an attainable reality for all. The ongoing advancements in this field will undoubtedly shape the future of mobility, making it more efficient, sustainable, and accessible.

Cost-Effectiveness of Advanced In-Wheel Motors in EVs

The automotive industry is undergoing a significant transformation, particularly with the rise of electric vehicles (EVs). As manufacturers strive to enhance performance while keeping costs manageable, advanced in-wheel motors have emerged as a promising solution. These innovative components not only improve the efficiency of electric drivetrains but also contribute to the overall cost-effectiveness of EVs. By integrating the motor directly into the wheel assembly, manufacturers can reduce the complexity of traditional drivetrain systems, which often involve multiple components such as gearboxes and differentials. This simplification leads to a reduction in manufacturing costs, making it feasible to produce high-performance electric vehicles at more accessible price points.

Moreover, the compact design of in-wheel motors allows for greater flexibility in vehicle design. With fewer mechanical components to accommodate, engineers can optimize the layout of the vehicle, potentially increasing cabin space or enhancing aerodynamics. This design freedom can lead to lighter vehicles, which in turn improves energy efficiency and extends the driving range. As consumers increasingly prioritize range and performance, the ability to offer a lightweight, high-performing vehicle at a competitive price becomes a significant advantage in the marketplace.

In addition to manufacturing efficiencies, in-wheel motors can also enhance the overall driving experience. By providing direct drive to each wheel, these motors enable precise control over torque distribution, which can significantly improve handling and stability. This capability allows for advanced features such as torque vectoring, where power is dynamically allocated to individual wheels based on driving conditions. Such innovations not only enhance performance but also contribute to safety, making EVs equipped with in-wheel motors more appealing to a broader audience.

Furthermore, the cost-effectiveness of in-wheel motors extends beyond initial manufacturing. The reduction in mechanical complexity often translates to lower maintenance costs over the vehicle’s lifespan. Traditional drivetrains require regular maintenance and potential repairs, which can add to the total cost of ownership. In contrast, in-wheel motors, with fewer moving parts and a more straightforward design, are likely to require less frequent servicing. This aspect is particularly attractive to consumers who are increasingly concerned about the long-term financial implications of their vehicle purchases.

As the demand for electric vehicles continues to grow, the need for cost-effective solutions becomes more pressing. In-wheel motors represent a significant step forward in addressing this challenge. By lowering production costs, enhancing vehicle performance, and reducing maintenance requirements, these advanced motors can help make high-performance electric vehicles more affordable for the average consumer. This democratization of technology is crucial in accelerating the transition to electric mobility, as it allows a wider range of consumers to access the benefits of EVs.

In conclusion, the integration of advanced in-wheel motors into electric vehicles is poised to revolutionize the industry by making high-performance options more affordable. The combination of reduced manufacturing complexity, improved driving dynamics, and lower maintenance costs positions in-wheel motors as a key player in the future of electric mobility. As manufacturers continue to innovate and refine these technologies, the potential for widespread adoption of affordable, high-performance electric vehicles becomes increasingly attainable, paving the way for a more sustainable automotive landscape.

Enhancing Efficiency: The Role of In-Wheel Motors in EV Design

The evolution of electric vehicles (EVs) has been marked by significant technological advancements, with in-wheel motors emerging as a transformative component in the design and performance of these vehicles. By integrating the motor directly into the wheel hub, manufacturers can optimize space, reduce weight, and enhance overall efficiency. This innovative approach not only streamlines the vehicle’s architecture but also allows for a more effective distribution of power, which is crucial for maximizing the performance of electric drivetrains.

One of the primary advantages of in-wheel motors is their ability to improve energy efficiency. Traditional EV designs often rely on centralized motors that transmit power through a series of mechanical components, including driveshafts and differentials. This configuration can lead to energy losses due to friction and inertia. In contrast, in-wheel motors eliminate many of these mechanical linkages, resulting in a more direct transfer of power from the motor to the wheels. Consequently, this design minimizes energy loss and enhances the overall efficiency of the vehicle, allowing for longer ranges on a single charge.

Moreover, the compact nature of in-wheel motors contributes to a more flexible vehicle design. By freeing up space that would typically be occupied by a conventional motor and its associated components, manufacturers can explore new design possibilities. This flexibility can lead to innovative vehicle layouts, such as lower center of gravity configurations, which improve handling and stability. Additionally, the ability to distribute motors across all four wheels enables advanced torque vectoring capabilities. This technology allows for precise control of power delivery to each wheel, enhancing traction and stability, particularly in challenging driving conditions.

As the automotive industry increasingly prioritizes sustainability, the role of in-wheel motors in enhancing the efficiency of EVs becomes even more significant. The reduction in weight associated with eliminating traditional drivetrain components not only improves energy efficiency but also contributes to lower manufacturing costs. This cost-effectiveness is particularly important as the industry strives to make electric vehicles more accessible to a broader audience. By lowering production costs, manufacturers can offer high-performance EVs at more competitive prices, thereby accelerating the transition to electric mobility.

In addition to their efficiency and design benefits, in-wheel motors also facilitate advancements in regenerative braking systems. This technology allows vehicles to recover energy during braking, converting kinetic energy back into stored electrical energy. With in-wheel motors, the integration of regenerative braking becomes more seamless, as each wheel can independently manage its braking force. This capability not only enhances energy recovery but also improves overall vehicle control and safety.

Furthermore, the adoption of in-wheel motors aligns with the growing trend of electrification in various vehicle segments, including commercial and public transportation. As cities seek to reduce emissions and improve air quality, the demand for efficient electric buses and delivery vehicles is on the rise. In-wheel motors can play a pivotal role in meeting these demands, offering the necessary performance and efficiency to support the electrification of urban transport systems.

In conclusion, the integration of advanced in-wheel motors into electric vehicle design represents a significant leap forward in enhancing efficiency and performance. By streamlining power delivery, reducing weight, and enabling innovative design possibilities, these motors are poised to revolutionize the EV landscape. As manufacturers continue to explore the potential of in-wheel motors, the future of electric mobility looks increasingly promising, paving the way for more affordable, high-performance vehicles that meet the demands of a sustainable world.

The Future of Affordable High-Performance Electric Vehicles

The future of affordable high-performance electric vehicles (EVs) is poised for a significant transformation, largely driven by advancements in technology, particularly in the realm of in-wheel motors. As the automotive industry continues to evolve, the integration of these innovative components is set to redefine the performance and accessibility of electric vehicles. In-wheel motors, which are integrated directly into the wheel hub, offer a multitude of advantages that can enhance both the driving experience and the overall efficiency of EVs.

One of the most compelling benefits of in-wheel motors is their ability to reduce weight and complexity in vehicle design. Traditional electric vehicles typically rely on a centralized motor and complex drivetrain systems, which can add unnecessary weight and reduce efficiency. In contrast, in-wheel motors eliminate the need for a bulky transmission and drive shafts, allowing for a more streamlined design. This reduction in weight not only improves energy efficiency but also enhances vehicle handling and performance. As a result, manufacturers can create lighter, more agile vehicles that deliver an exhilarating driving experience without compromising on range.

Moreover, the modular nature of in-wheel motors allows for greater flexibility in vehicle design. Automakers can easily adjust the number of motors and their placement to optimize performance for various vehicle types, from compact cars to high-performance sports models. This adaptability opens the door for a new generation of electric vehicles that can cater to diverse consumer preferences, making high-performance options more accessible to a broader audience. As the market for electric vehicles expands, the ability to offer customizable performance features will be a significant advantage for manufacturers looking to differentiate themselves in a competitive landscape.

In addition to enhancing performance, in-wheel motors contribute to improved energy efficiency. By placing the motors directly at the wheels, manufacturers can achieve better torque distribution and traction control. This direct drive system allows for instantaneous power delivery, which is crucial for high-performance applications. Furthermore, the ability to independently control each wheel can lead to advanced handling capabilities, such as torque vectoring, which enhances stability and cornering performance. As a result, consumers can expect a more dynamic driving experience that rivals traditional internal combustion engine vehicles.

The economic implications of in-wheel motors are equally noteworthy. As production techniques advance and economies of scale are realized, the cost of manufacturing these motors is expected to decrease. This reduction in production costs can translate into lower prices for consumers, making high-performance electric vehicles more attainable. Additionally, as the demand for sustainable transportation solutions continues to grow, the affordability of EVs will play a crucial role in encouraging widespread adoption. By making high-performance electric vehicles accessible to a larger segment of the population, in-wheel motors can help accelerate the transition to a more sustainable automotive future.

In conclusion, the integration of advanced in-wheel motors represents a pivotal development in the evolution of affordable high-performance electric vehicles. By reducing weight, enhancing design flexibility, improving energy efficiency, and lowering production costs, these innovative components are set to revolutionize the automotive landscape. As manufacturers embrace this technology, consumers can look forward to a new era of electric vehicles that not only deliver exceptional performance but also align with the growing demand for sustainable transportation solutions. The future of affordable high-performance electric vehicles is bright, and in-wheel motors are at the forefront of this exciting transformation.

Overcoming Challenges: Integrating In-Wheel Motors into Mainstream EVs

The integration of advanced in-wheel motors into mainstream electric vehicles (EVs) represents a significant leap forward in automotive technology, promising to enhance performance while simultaneously addressing cost concerns. However, the journey toward widespread adoption of this innovative propulsion system is not without its challenges. One of the primary hurdles is the need for manufacturers to adapt existing vehicle architectures to accommodate the unique design and operational requirements of in-wheel motors. Unlike traditional powertrains, which centralize the motor and drivetrain components, in-wheel motors distribute power directly to the wheels, necessitating a rethinking of vehicle dynamics, weight distribution, and suspension systems.

Moreover, the engineering complexities associated with in-wheel motors cannot be understated. These motors must be compact yet powerful enough to deliver the torque and acceleration that consumers expect from high-performance vehicles. This requirement places significant demands on materials and manufacturing processes, as engineers strive to create lightweight yet durable components that can withstand the rigors of daily driving. Additionally, the integration of in-wheel motors raises concerns about heat dissipation and reliability, as the motors are exposed to various environmental conditions and stresses that traditional motors are shielded from. Addressing these issues requires innovative cooling solutions and robust designs that can endure the challenges of real-world use.

Another critical aspect of integrating in-wheel motors into mainstream EVs is the need for advanced control systems. The unique configuration of in-wheel motors necessitates sophisticated algorithms to manage torque distribution and ensure optimal traction and stability. This complexity can lead to increased development costs and longer timelines for bringing new models to market. Furthermore, manufacturers must invest in extensive testing and validation processes to ensure that these systems perform reliably under a wide range of driving conditions. As a result, the transition to in-wheel motor technology may initially appear daunting, particularly for established automakers accustomed to traditional powertrain designs.

Despite these challenges, the potential benefits of in-wheel motors are driving significant interest and investment in this technology. By enabling greater design flexibility, in-wheel motors can facilitate the creation of lighter, more efficient vehicles that do not compromise on performance. This is particularly relevant in the context of the growing demand for affordable high-performance EVs, as consumers increasingly seek vehicles that offer both speed and sustainability. The ability to optimize weight distribution and lower the center of gravity can enhance handling and ride quality, making in-wheel motors an attractive option for manufacturers aiming to differentiate their products in a competitive market.

Furthermore, as battery technology continues to advance, the synergy between in-wheel motors and improved energy storage solutions could lead to even greater efficiencies. The potential for regenerative braking systems integrated into the in-wheel motors can enhance energy recovery, further extending the range of EVs and reducing the overall cost of ownership. As manufacturers navigate the complexities of integrating this technology, collaboration with research institutions and technology firms will be essential to overcome engineering challenges and accelerate the development of viable in-wheel motor solutions.

In conclusion, while the integration of in-wheel motors into mainstream EVs presents a series of challenges, the potential rewards are substantial. By addressing engineering complexities, enhancing control systems, and leveraging advancements in battery technology, the automotive industry can pave the way for a new era of affordable high-performance electric vehicles. As these innovations continue to evolve, they hold the promise of transforming the driving experience, making sustainable transportation more accessible and appealing to a broader audience.

Case Studies: Successful Implementations of In-Wheel Motor Technology

The automotive industry is undergoing a significant transformation, particularly with the rise of electric vehicles (EVs). Among the various innovations driving this change, in-wheel motor technology stands out as a game-changer, offering a unique approach to vehicle design and performance. Several case studies illustrate the successful implementation of this technology, showcasing its potential to revolutionize the EV market by enhancing performance while simultaneously reducing costs.

One notable example is the work done by Protean Electric, a company that has pioneered the development of in-wheel motors. Their technology has been integrated into various vehicle prototypes, demonstrating the feasibility and advantages of this approach. By placing the electric motors directly within the wheel hubs, Protean Electric has managed to eliminate the need for traditional drivetrain components, such as gearboxes and differentials. This not only simplifies the vehicle architecture but also reduces weight, which is a critical factor in enhancing overall efficiency. In their trials, vehicles equipped with Protean’s in-wheel motors exhibited improved acceleration and handling, proving that this technology can deliver high performance without the complexity of conventional systems.

Another compelling case study is the collaboration between the automotive manufacturer Renault and the in-wheel motor technology firm, Michelin. Together, they developed the Michelin Vision concept, which features in-wheel motors that provide both propulsion and advanced control over the vehicle’s dynamics. This partnership highlights the potential for in-wheel motors to enhance not only performance but also safety and driving experience. The Vision concept demonstrated remarkable agility and responsiveness, showcasing how in-wheel motors can facilitate precise torque vectoring, allowing for better traction and stability during various driving conditions. This innovative approach has the potential to set new standards for performance in the EV sector.

Furthermore, the implementation of in-wheel motors has been explored in the context of urban mobility solutions. The case of the electric scooter manufacturer, Gogoro, illustrates how this technology can be adapted for smaller, more agile vehicles. By integrating in-wheel motors into their scooters, Gogoro has achieved a compact design that maximizes space efficiency while providing robust performance. The scooters are not only lightweight but also capable of rapid acceleration, making them ideal for navigating congested urban environments. This successful application of in-wheel motor technology demonstrates its versatility and potential to enhance various forms of electric transportation.

In addition to these examples, the automotive industry is witnessing a growing interest in in-wheel motors from various manufacturers looking to differentiate their offerings in a competitive market. Companies like BMW and Volkswagen are exploring the integration of this technology into their future EV models, recognizing the advantages it brings in terms of performance, efficiency, and design flexibility. As these manufacturers invest in research and development, the potential for widespread adoption of in-wheel motors becomes increasingly plausible.

In conclusion, the successful implementations of in-wheel motor technology across various case studies highlight its transformative potential within the electric vehicle landscape. By simplifying vehicle architecture, enhancing performance, and enabling innovative designs, in-wheel motors are poised to play a crucial role in making high-performance EVs more affordable and accessible. As the automotive industry continues to evolve, the lessons learned from these implementations will undoubtedly inform future developments, paving the way for a new era of electric mobility that prioritizes both performance and sustainability.

Q&A

1. **What are in-wheel motors?**

In-wheel motors are electric motors that are integrated directly into the wheel hub of a vehicle, allowing for direct drive to the wheels without the need for traditional drivetrain components.

2. **How do in-wheel motors improve performance in electric vehicles (EVs)?**

In-wheel motors enhance performance by providing instant torque, improving acceleration, and allowing for better weight distribution, which can lead to improved handling and stability.

3. **What is the impact of in-wheel motors on the cost of EVs?**

In-wheel motors can reduce manufacturing costs by simplifying the drivetrain and reducing the number of mechanical components, potentially making high-performance EVs more affordable.

4. **How do in-wheel motors contribute to energy efficiency in EVs?**

In-wheel motors can improve energy efficiency by minimizing energy loss associated with traditional drivetrains, allowing for more efficient power delivery and potentially extending the vehicle’s range.

5. **What are the challenges associated with in-wheel motor technology?**

Challenges include increased unsprung weight, potential for higher wear on tires, and the need for advanced cooling systems to manage heat generated by the motors.

6. **What is the future outlook for in-wheel motors in the EV market?**

The future outlook is promising, with ongoing advancements in technology and materials that may overcome current challenges, leading to wider adoption and further innovation in high-performance, affordable EVs.The integration of advanced in-wheel motors in electric vehicles (EVs) represents a significant leap forward in automotive technology, enabling enhanced performance, efficiency, and affordability. By decentralizing power delivery and reducing the need for complex drivetrain components, in-wheel motors facilitate lighter vehicle designs and improved handling. This innovation not only lowers manufacturing costs but also enhances the driving experience through instant torque and precise control. As a result, the widespread adoption of in-wheel motor technology has the potential to revolutionize the EV market, making high-performance electric vehicles more accessible to a broader audience while contributing to the overall sustainability goals of the automotive industry.