Inside the M4 MacBook Pro: A Teardown and Repairability Guide offers an in-depth exploration of Apple’s latest powerhouse laptop, providing tech enthusiasts and repair professionals with a comprehensive look at its internal components and design intricacies. This guide meticulously dissects the M4 MacBook Pro, revealing the engineering marvels and challenges that lie beneath its sleek exterior. From the innovative M4 chip architecture to the advanced thermal management system, each section of the teardown highlights the technological advancements and potential repair hurdles. Whether you’re a curious consumer or a seasoned technician, this guide equips you with the knowledge to understand, maintain, and potentially repair one of Apple’s most sophisticated devices to date.

Understanding the M4 MacBook Pro’s Internal Architecture

The M4 MacBook Pro represents a significant leap in Apple’s laptop technology, offering a blend of power, efficiency, and sleek design. Understanding its internal architecture is crucial for both enthusiasts and professionals who seek to appreciate its engineering marvel or undertake repair tasks. At the heart of the M4 MacBook Pro lies the Apple M4 chip, a testament to Apple’s commitment to integrating hardware and software seamlessly. This chip, with its advanced neural engine and enhanced GPU capabilities, ensures that the MacBook Pro delivers unparalleled performance, whether for intensive graphic design tasks or complex computational processes.

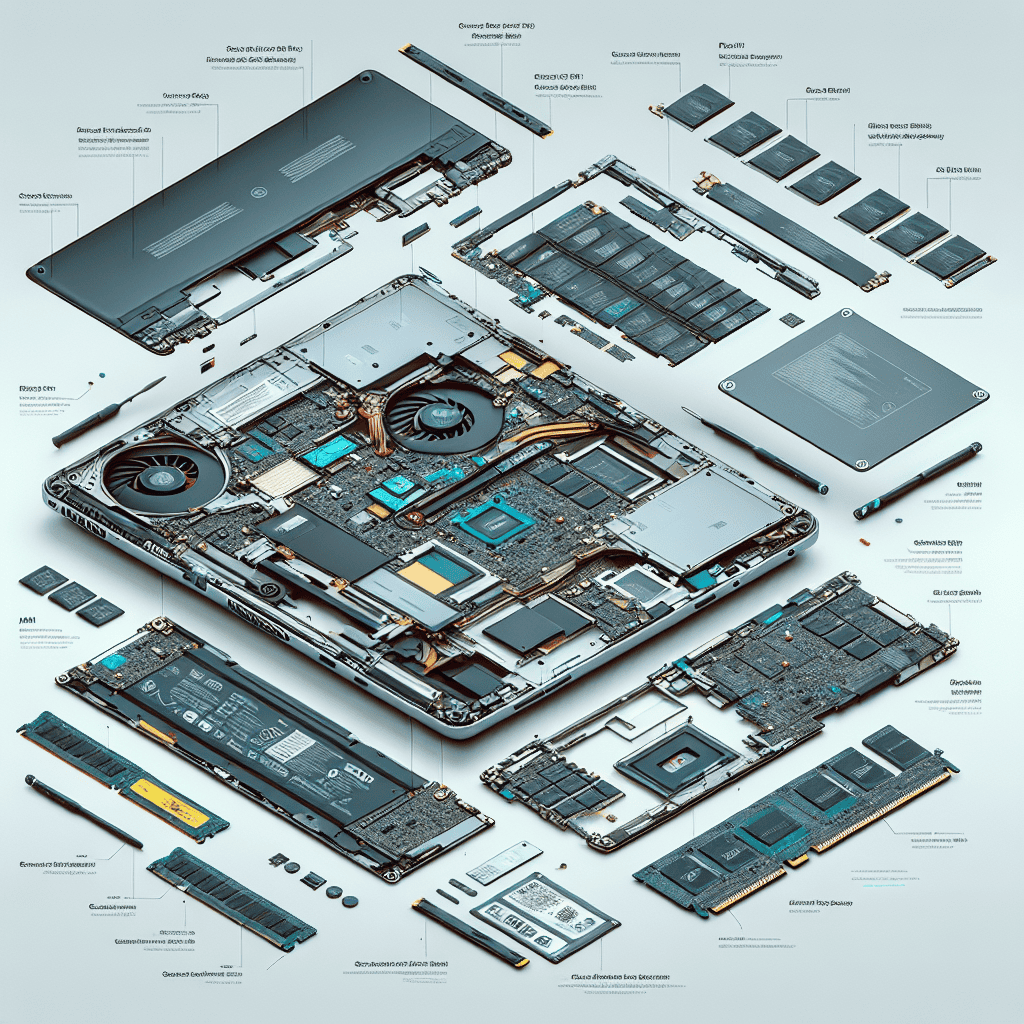

Transitioning from the chip, the logic board of the M4 MacBook Pro is a compact yet intricate assembly. It houses not only the M4 chip but also the RAM, which is soldered directly onto the board. This design choice, while optimizing space and performance, poses challenges for repairability. Users seeking to upgrade their RAM will find it impossible, necessitating careful consideration of their memory needs at the time of purchase. Furthermore, the SSD storage is also soldered, reinforcing the importance of selecting the appropriate configuration initially.

Moving on to the cooling system, Apple has implemented an innovative thermal architecture to manage the heat generated by the powerful M4 chip. The dual-fan setup, coupled with strategically placed heat pipes, ensures efficient heat dissipation, maintaining optimal performance even under heavy workloads. This design not only enhances the laptop’s longevity but also contributes to its whisper-quiet operation, a feature highly appreciated by users who require a distraction-free environment.

In terms of connectivity, the M4 MacBook Pro offers a range of ports, including Thunderbolt 4, which provides high-speed data transfer and versatile connectivity options. The placement of these ports is designed to maximize convenience while maintaining the device’s slim profile. However, the limited number of ports may necessitate the use of adapters or hubs for users with multiple peripheral devices.

The display assembly of the M4 MacBook Pro is another area of interest. The Retina display, with its high resolution and vibrant color accuracy, is a standout feature. However, the integration of the display and the top case means that any damage to the screen could require a complete replacement of the assembly, which can be costly. This design choice underscores the importance of protective measures, such as screen protectors and careful handling.

Battery technology in the M4 MacBook Pro has also seen advancements, with a high-capacity lithium-polymer battery that promises extended usage time. The battery is adhered to the chassis, making replacement a meticulous task that requires specialized tools and expertise. This aspect of the design highlights the trade-off between achieving a slim form factor and maintaining ease of repair.

In conclusion, the M4 MacBook Pro’s internal architecture is a blend of cutting-edge technology and design efficiency. While it offers remarkable performance and a sleek aesthetic, its repairability is limited by the integration and soldering of key components. For users, this means that while they can enjoy a high-performing device, they must also be mindful of their initial configuration choices and handle the device with care to avoid costly repairs. Understanding these aspects is essential for anyone looking to delve into the intricacies of the M4 MacBook Pro, whether for appreciation or maintenance purposes.

Key Components of the M4 MacBook Pro: A Detailed Breakdown

The M4 MacBook Pro represents a significant leap in Apple’s laptop technology, combining cutting-edge performance with sleek design. To understand what makes this device so remarkable, a detailed examination of its key components is essential. This teardown and repairability guide aims to provide an in-depth look at the internal architecture of the M4 MacBook Pro, offering insights into its construction and potential for repair.

At the heart of the M4 MacBook Pro lies the Apple M4 chip, a marvel of engineering that integrates the CPU, GPU, and Neural Engine into a single unit. This chip is designed to deliver unparalleled performance and efficiency, making it the cornerstone of the device’s capabilities. The M4 chip’s architecture is based on a 5-nanometer process, which allows for more transistors to be packed into a smaller space, resulting in faster processing speeds and improved energy efficiency. This advancement not only enhances the overall performance of the MacBook Pro but also contributes to its impressive battery life.

Transitioning to the memory and storage components, the M4 MacBook Pro features unified memory architecture, which allows the CPU and GPU to access the same memory pool. This design choice reduces latency and increases bandwidth, leading to smoother multitasking and faster data processing. The device is available with various memory configurations, ranging from 16GB to 64GB, catering to different user needs. Additionally, the solid-state drive (SSD) options provide ample storage space, with capacities up to 8TB, ensuring that users have sufficient room for their files and applications.

The display of the M4 MacBook Pro is another standout feature, boasting a Liquid Retina XDR screen that offers stunning visuals with high dynamic range and exceptional color accuracy. This display is ideal for creative professionals who require precise color representation for their work. The integration of ProMotion technology further enhances the user experience by providing a refresh rate of up to 120Hz, resulting in smoother scrolling and more responsive interactions.

Moving on to the cooling system, the M4 MacBook Pro employs an advanced thermal design to manage heat dissipation effectively. The inclusion of a larger heat sink and improved airflow mechanisms ensures that the device remains cool even under heavy workloads. This thermal efficiency is crucial for maintaining optimal performance and prolonging the lifespan of the internal components.

In terms of connectivity, the M4 MacBook Pro is equipped with a range of ports, including Thunderbolt 4, USB-C, and an SD card slot, providing users with versatile options for connecting peripherals and external devices. The inclusion of MagSafe charging technology marks a return to a beloved feature, offering a secure and convenient way to power the device.

When considering repairability, the M4 MacBook Pro presents both challenges and opportunities. While the integration of components such as the M4 chip and unified memory enhances performance, it also complicates repairs, as these parts are soldered onto the motherboard. However, certain components, like the battery and SSD, are more accessible and can be replaced with relative ease by skilled technicians.

In conclusion, the M4 MacBook Pro is a testament to Apple’s commitment to innovation and design excellence. Its key components, from the powerful M4 chip to the stunning display, work in harmony to deliver a superior user experience. While repairability may pose some challenges, understanding the intricacies of its internal architecture provides valuable insights for those looking to maintain or upgrade their device.

Step-by-Step Guide to Teardown the M4 MacBook Pro

The M4 MacBook Pro, Apple’s latest iteration in its line of high-performance laptops, has garnered significant attention for its impressive specifications and sleek design. However, for those interested in understanding the inner workings of this technological marvel or considering repairs, a detailed teardown is essential. This guide aims to provide a comprehensive step-by-step walkthrough of the teardown process, ensuring that enthusiasts and technicians alike can navigate the intricacies of the M4 MacBook Pro with confidence.

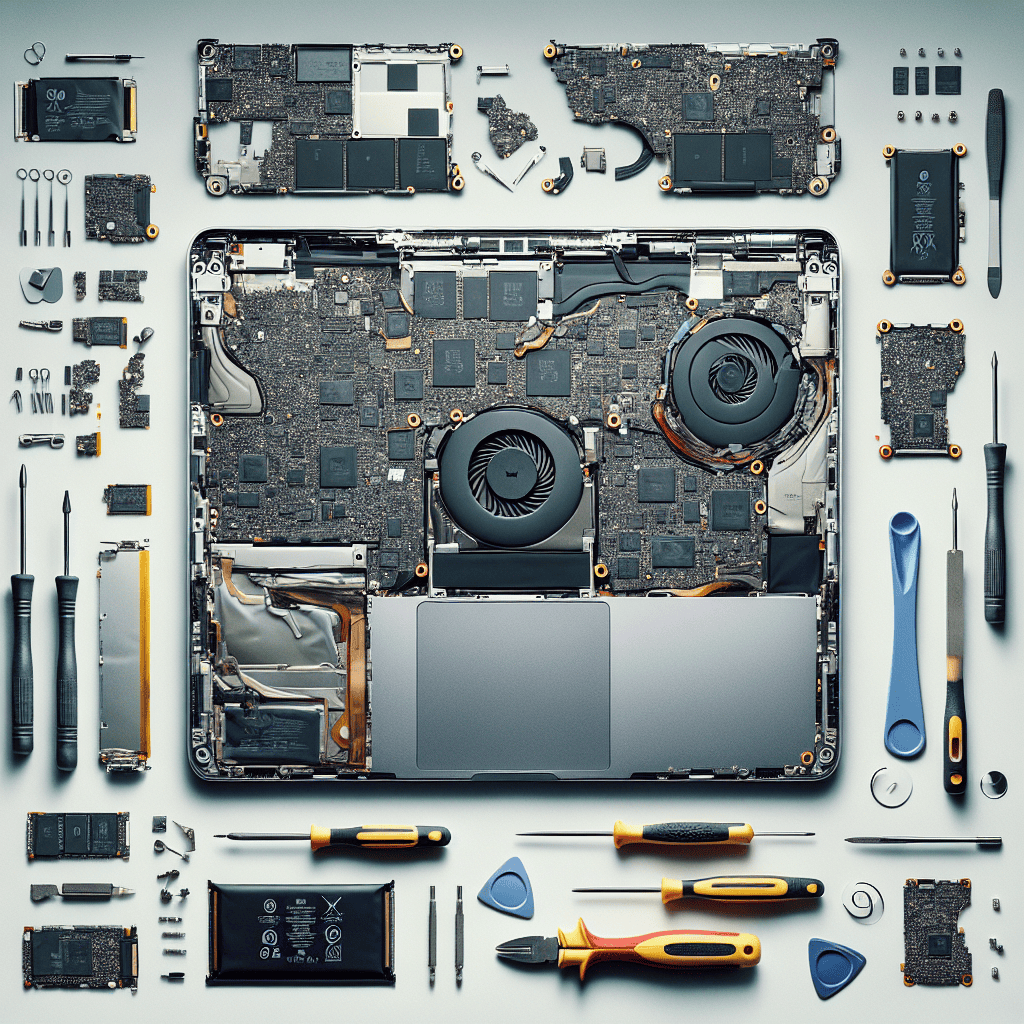

To begin with, it is crucial to gather the necessary tools for the teardown. A set of precision screwdrivers, a spudger, tweezers, and an anti-static wrist strap are indispensable for this task. Ensuring that you have a clean, well-lit workspace will also facilitate a smoother process. Once prepared, the first step involves turning off the MacBook Pro and disconnecting it from any power source. This precautionary measure is vital to prevent any electrical mishaps during the teardown.

Next, flip the MacBook Pro over to access the bottom case. Using a Pentalobe screwdriver, carefully remove the screws securing the bottom cover. It is advisable to keep track of the screws, as they may vary in size and length. With the screws removed, gently lift the bottom cover using a spudger, taking care not to damage the clips that hold it in place. This action reveals the internal components of the M4 MacBook Pro, providing a glimpse into its sophisticated architecture.

Transitioning to the battery, which is a critical component, it is essential to disconnect it before proceeding further. Locate the battery connector and use a spudger to carefully disconnect it from the logic board. This step ensures that the device is completely powered down, minimizing the risk of short circuits. With the battery safely disconnected, attention can now be directed towards the logic board and other internal components.

The logic board, a central element of the MacBook Pro’s functionality, is secured by several screws and connectors. Begin by disconnecting the various ribbon cables and connectors attached to the logic board. It is important to handle these components with care, as they are delicate and can be easily damaged. Once all connections are safely detached, remove the screws securing the logic board and gently lift it out of the chassis.

As the teardown progresses, other components such as the SSD, RAM, and cooling system can be accessed and removed if necessary. The SSD, typically located near the logic board, can be unscrewed and lifted out with ease. Similarly, the RAM modules, if not soldered, can be carefully removed by releasing the clips that hold them in place. The cooling system, comprising fans and heat sinks, can also be detached by unscrewing the relevant fasteners.

Throughout this process, it is imperative to maintain an organized approach, keeping track of all screws and components. This attention to detail will prove invaluable during reassembly. Moreover, while the M4 MacBook Pro is designed with precision, it is worth noting that some components may not be user-replaceable due to Apple’s design choices. Therefore, understanding the limitations of repairability is crucial.

In conclusion, the teardown of the M4 MacBook Pro offers a fascinating insight into its advanced engineering. By following this step-by-step guide, individuals can explore the device’s internal components with confidence, whether for educational purposes or repair endeavors. As technology continues to evolve, such knowledge becomes increasingly valuable, empowering users to engage more deeply with their devices.

Assessing the Repairability of the M4 MacBook Pro

The M4 MacBook Pro, Apple’s latest iteration in its line of high-performance laptops, has garnered significant attention for its impressive specifications and sleek design. However, beyond the surface-level allure, a critical aspect that demands examination is its repairability. Understanding the repairability of a device is crucial for consumers who wish to maintain their investment over time, as well as for technicians who may be tasked with servicing these machines. In this regard, a detailed teardown of the M4 MacBook Pro provides valuable insights into its internal architecture and the feasibility of repairs.

Upon opening the M4 MacBook Pro, one is immediately struck by the meticulous organization of its components. Apple has long been known for its precision engineering, and this model is no exception. The internal layout is both compact and efficient, with components such as the logic board, battery, and cooling system strategically positioned to optimize performance and thermal management. However, this compactness also presents challenges when it comes to repairability. The densely packed internals mean that accessing certain components requires careful disassembly, which can be daunting for those unfamiliar with the intricacies of modern laptop design.

One of the most significant factors affecting the repairability of the M4 MacBook Pro is the use of proprietary screws and adhesives. Apple has employed a variety of specialized screws that necessitate specific tools for removal, thereby complicating the disassembly process for the average user. Additionally, the extensive use of adhesive to secure components such as the battery and display assembly further complicates repairs. While adhesives contribute to the device’s slim profile and structural integrity, they also make it more challenging to replace parts without causing damage.

Despite these challenges, certain aspects of the M4 MacBook Pro’s design do facilitate repairability. For instance, the modular nature of some components, such as the SSD and RAM, allows for relatively straightforward upgrades or replacements. This modularity is a welcome feature for users who may wish to enhance their device’s performance or extend its lifespan. Furthermore, Apple’s decision to incorporate a more accessible battery design in this model is a positive step towards improving repairability. The battery, while still secured with adhesive, is more easily removable than in previous iterations, reducing the risk of damage during replacement.

Moreover, the availability of official repair manuals and parts from Apple has improved in recent years, reflecting a shift towards greater transparency and support for independent repair efforts. This change is significant, as it empowers both consumers and third-party technicians to undertake repairs with confidence, knowing they have access to the necessary resources and guidance.

In conclusion, while the M4 MacBook Pro presents certain challenges in terms of repairability due to its compact design and use of proprietary components, it also offers some redeeming features that facilitate maintenance and upgrades. The balance between sleek design and repairability is a delicate one, and Apple has made strides in addressing consumer concerns in this area. As technology continues to evolve, it is imperative for manufacturers to prioritize repairability alongside innovation, ensuring that devices remain both cutting-edge and sustainable. For those considering the M4 MacBook Pro, understanding its repairability is an essential aspect of making an informed purchasing decision, ultimately contributing to a more sustainable approach to technology consumption.

Common Repair Challenges in the M4 MacBook Pro

The M4 MacBook Pro, with its sleek design and powerful performance, has captured the attention of tech enthusiasts and professionals alike. However, as with any sophisticated piece of technology, it presents certain challenges when it comes to repairability. Understanding these challenges is crucial for anyone attempting to maintain or repair their device. One of the most common repair challenges in the M4 MacBook Pro is accessing the internal components. Apple has continued its trend of prioritizing a compact and seamless design, which often means that components are tightly packed and secured with proprietary screws. This design choice, while aesthetically pleasing and beneficial for portability, complicates the disassembly process. To address this, specialized tools are required to safely open the device without causing damage to the delicate casing or internal components.

Moreover, the integration of components poses another significant challenge. The M4 MacBook Pro features a highly integrated logic board, where many essential components such as the CPU, GPU, and RAM are soldered directly onto the board. This integration enhances performance and efficiency but limits the ability to upgrade or replace individual components. Consequently, if one component fails, it may necessitate replacing the entire logic board, which can be costly and time-consuming. This aspect of repairability is a critical consideration for users who prioritize long-term device sustainability and cost-effectiveness.

Transitioning to another common issue, the battery replacement process in the M4 MacBook Pro also presents its own set of challenges. The battery is adhered to the chassis with strong adhesive, making it difficult to remove without the risk of puncturing or damaging it. This design choice is intended to maximize battery capacity and device thinness, yet it complicates the replacement process. Technicians must exercise extreme caution and use appropriate tools to safely detach the battery, ensuring that no harm comes to the device or the individual performing the repair.

In addition to these hardware challenges, software-related issues can also arise during repairs. The M4 MacBook Pro is equipped with Apple’s latest security features, including the T2 security chip, which enhances data protection but can complicate repairs. This chip requires specific software tools and authentication processes to access certain system functions, which can be a hurdle for independent repair technicians. Understanding these software intricacies is essential for anyone attempting to perform repairs on the M4 MacBook Pro, as it ensures that the device remains secure and fully functional post-repair.

Furthermore, the display assembly in the M4 MacBook Pro is another area where repair challenges are prevalent. The Retina display, known for its stunning clarity and color accuracy, is a delicate component that requires careful handling. Replacing or repairing the display involves navigating fragile connectors and ensuring that the screen is properly aligned and secured. Any missteps in this process can result in display malfunctions or damage, underscoring the importance of precision and expertise in handling such repairs.

In conclusion, while the M4 MacBook Pro is a marvel of modern engineering, its repairability presents several challenges that require careful consideration and expertise. From accessing tightly packed components to navigating software security features, each step in the repair process demands a thorough understanding of the device’s design and functionality. By acknowledging these challenges and equipping oneself with the necessary tools and knowledge, users and technicians can effectively address common repair issues, ensuring the longevity and optimal performance of their M4 MacBook Pro.

Tools and Tips for Safely Repairing the M4 MacBook Pro

When embarking on the journey of repairing the M4 MacBook Pro, it is essential to equip oneself with the right tools and knowledge to ensure a safe and effective process. The M4 MacBook Pro, with its sleek design and advanced technology, presents unique challenges and opportunities for those looking to perform repairs. To begin with, having a comprehensive toolkit is crucial. A precision screwdriver set, including Pentalobe, Torx, and Phillips heads, is indispensable for accessing the internal components of the MacBook Pro. Additionally, a spudger and a pair of tweezers are necessary for delicately handling small parts and connectors without causing damage.

Moreover, an anti-static wrist strap is highly recommended to prevent electrostatic discharge, which can irreparably harm sensitive electronic components. As you prepare to open the device, it is important to work in a clean, well-lit environment to avoid losing any small screws or parts. A magnetic project mat can be particularly useful for organizing screws and components, ensuring that reassembly is as smooth as possible. Transitioning to the actual teardown, the first step involves removing the Pentalobe screws on the bottom case. Gently prying open the case with a spudger reveals the intricate layout of the M4 MacBook Pro’s internals.

Once inside, it is crucial to disconnect the battery before proceeding with any further disassembly. This step is vital for safety and to prevent any accidental short circuits. The battery connector can be carefully detached using a plastic spudger, ensuring no metal tools come into contact with the battery terminals. With the power source safely disconnected, attention can be turned to the specific component requiring repair or replacement. Whether it is the SSD, RAM, or cooling fan, each part is secured with its own set of screws and connectors, necessitating a methodical approach to disassembly.

For instance, when replacing the SSD, it is important to note that the M4 MacBook Pro utilizes a proprietary design, meaning that only compatible SSDs can be used as replacements. Carefully unscrewing the SSD bracket and gently sliding out the drive allows for a seamless swap. Similarly, when addressing issues with the cooling fan, it is essential to clean any accumulated dust and debris, which can impede performance and lead to overheating. A can of compressed air can be used to blow away dust, ensuring optimal airflow and cooling efficiency.

As the repair process concludes, reassembly requires the same level of care and attention to detail as disassembly. Ensuring that all connectors are securely reattached and that screws are returned to their original positions is paramount. It is advisable to double-check each step against a reliable guide or manual to avoid any oversight. Once the device is fully reassembled, reconnecting the battery and powering on the MacBook Pro will confirm the success of the repair.

In conclusion, repairing the M4 MacBook Pro demands a combination of the right tools, a meticulous approach, and a thorough understanding of the device’s architecture. By following these guidelines and exercising patience, one can safely and effectively perform repairs, extending the lifespan and functionality of this sophisticated piece of technology.

Q&A

1. **Question:** What is the primary focus of the “Inside the M4 MacBook Pro: A Teardown and Repairability Guide”?

**Answer:** The guide primarily focuses on disassembling the M4 MacBook Pro to assess its internal components and evaluate its repairability.

2. **Question:** What tools are typically required for the teardown of the M4 MacBook Pro?

**Answer:** Common tools required include a Pentalobe screwdriver, Torx screwdrivers, spudgers, tweezers, and suction handles.

3. **Question:** How does the M4 MacBook Pro’s battery design affect its repairability?

**Answer:** The battery is often glued in place, which can make it more challenging to replace, thus affecting the overall repairability negatively.

4. **Question:** What is a significant finding regarding the cooling system in the M4 MacBook Pro during the teardown?

**Answer:** The cooling system is typically compact and efficient, utilizing advanced thermal management techniques to maintain performance without excessive noise.

5. **Question:** How does the modularity of components in the M4 MacBook Pro impact its repairability score?

**Answer:** Higher modularity, such as easily replaceable SSDs or RAM, would improve the repairability score, but if components are soldered, it reduces the score.

6. **Question:** What is a common critique regarding the repairability of the M4 MacBook Pro based on the teardown?

**Answer:** A common critique is that many components are soldered or glued, making them difficult to replace or upgrade, which lowers the repairability score.The teardown and repairability guide for the M4 MacBook Pro reveals a mixed bag of design choices. While Apple has made strides in improving the device’s performance and efficiency with the M4 chip, the internal layout remains complex, with many components soldered or glued in place, limiting repairability. The use of proprietary screws and the integration of key components like RAM and storage onto the motherboard further complicate DIY repairs. However, some modular elements, such as the battery and trackpad, offer a glimmer of hope for those seeking to perform basic repairs. Overall, while the M4 MacBook Pro excels in technological advancement, it continues to challenge repair enthusiasts with its intricate design.