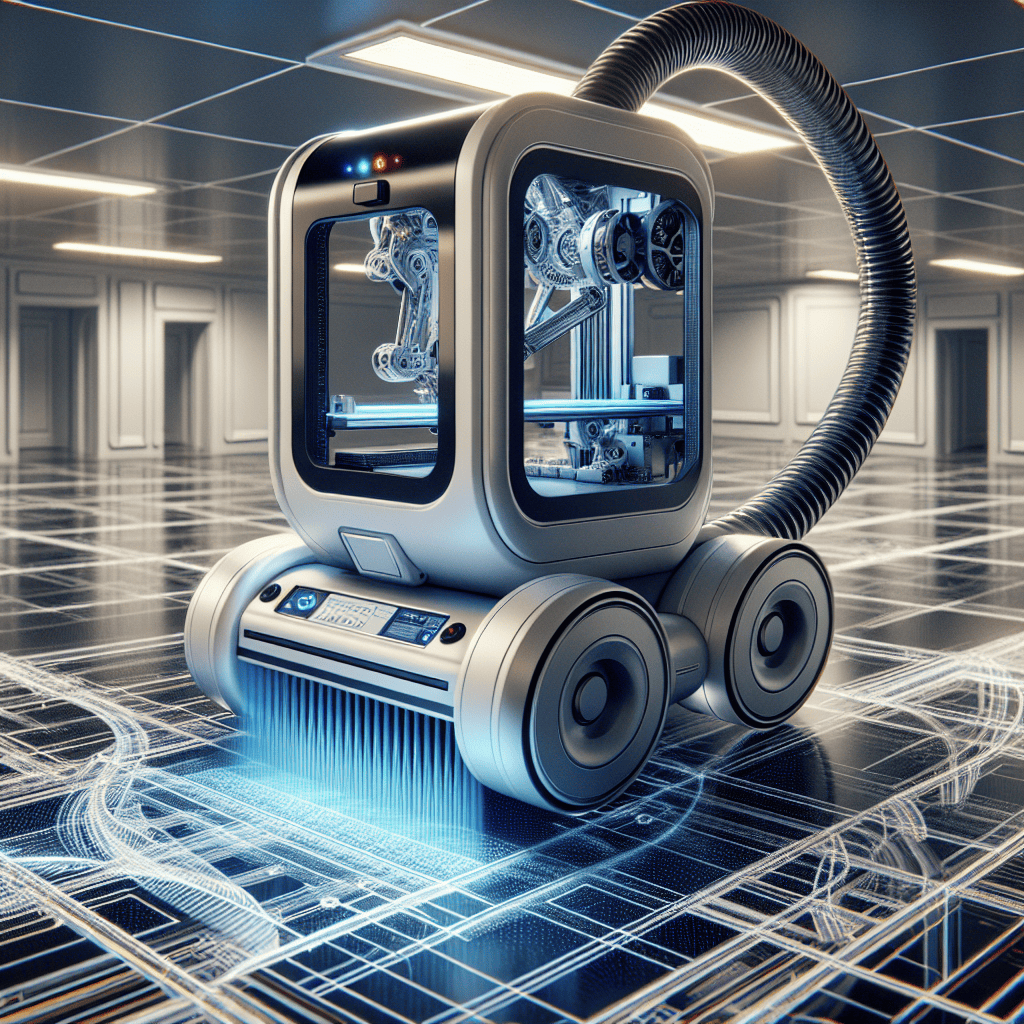

Introducing a groundbreaking advancement in the realm of additive manufacturing, the innovative mobile 3D printer with integrated vacuum robot technology is set to revolutionize floor printing capabilities. This cutting-edge device seamlessly combines the precision of 3D printing with the autonomous functionality of a vacuum robot, enabling it to navigate and print directly onto floor surfaces with unparalleled accuracy and efficiency. Designed to cater to a wide range of applications, from intricate decorative designs to functional floor layouts, this hybrid machine offers a versatile solution for both industrial and creative projects. Its ability to operate on various floor types and adapt to different environments makes it an invaluable tool for architects, designers, and manufacturers seeking to push the boundaries of traditional printing methods. With its user-friendly interface and advanced navigation system, this mobile 3D printer not only enhances productivity but also opens up new possibilities for innovation in floor design and customization.

Revolutionizing Home Decor: The Rise of Mobile 3D Printers with Vacuum Robot Integration

In recent years, the intersection of technology and home decor has seen remarkable advancements, with one of the most intriguing developments being the integration of mobile 3D printers with vacuum robots. This innovative combination is poised to revolutionize the way we approach interior design, offering unprecedented flexibility and creativity in personalizing living spaces. As we delve into this fascinating evolution, it becomes clear that the fusion of these technologies not only enhances functionality but also opens up new possibilities for artistic expression within the home.

To begin with, the concept of a mobile 3D printer integrated with a vacuum robot is a testament to the ingenuity of modern engineering. Traditionally, 3D printers have been stationary devices, limited by their fixed positions and the need for manual intervention. However, by incorporating the mobility and autonomous navigation capabilities of vacuum robots, these printers can now traverse across floors, creating intricate designs directly on surfaces. This mobility allows for a seamless transition from one area to another, enabling the creation of continuous patterns or distinct motifs throughout a room. Consequently, homeowners can now experiment with a variety of designs, from simple geometric shapes to complex artistic murals, all without the need for professional installation or extensive manual labor.

Moreover, the integration of vacuum robots into 3D printing technology brings about a significant enhancement in efficiency and precision. Vacuum robots are equipped with advanced sensors and mapping technologies, allowing them to navigate spaces with remarkable accuracy. When combined with 3D printing capabilities, these robots can meticulously follow pre-programmed designs, ensuring that every detail is executed with precision. This level of accuracy is particularly beneficial for intricate designs that require a high degree of detail, as it minimizes the risk of errors and ensures a flawless finish. Additionally, the ability to print directly onto floors eliminates the need for additional materials such as wallpaper or tiles, reducing waste and promoting sustainability.

Furthermore, the versatility of mobile 3D printers with vacuum robot integration extends beyond mere aesthetics. These devices can also be utilized for practical purposes, such as creating non-slip surfaces in areas prone to moisture or designing tactile pathways for visually impaired individuals. By offering both decorative and functional benefits, this technology caters to a wide range of needs and preferences, making it an invaluable tool for homeowners seeking to enhance their living environments.

In addition to their practical applications, these innovative devices also encourage a more personalized approach to home decor. With the ability to customize designs to suit individual tastes and preferences, homeowners can create unique spaces that reflect their personalities and lifestyles. This level of personalization is particularly appealing in an era where individuality and self-expression are highly valued. As a result, mobile 3D printers with vacuum robot integration are not only transforming the way we decorate our homes but also empowering individuals to take control of their interior design choices.

In conclusion, the rise of mobile 3D printers with vacuum robot integration marks a significant milestone in the evolution of home decor. By combining the mobility and precision of vacuum robots with the creative potential of 3D printing, this technology offers a new level of flexibility and personalization in interior design. As these devices continue to evolve and become more accessible, they are set to redefine the boundaries of home decor, offering endless possibilities for creativity and innovation.

How Mobile 3D Printers Are Transforming Floor Design with Vacuum Robot Technology

The advent of mobile 3D printers integrated with vacuum robot technology is revolutionizing the way we approach floor design, offering unprecedented flexibility and creativity. This innovative combination allows for the seamless integration of intricate designs directly onto floor surfaces, transforming traditional spaces into dynamic works of art. As technology continues to advance, the fusion of 3D printing and robotic vacuum capabilities is poised to redefine the boundaries of interior design, providing both aesthetic and functional benefits.

At the heart of this technological breakthrough is the ability of mobile 3D printers to move autonomously across a floor, much like a robotic vacuum cleaner. This mobility is facilitated by advanced navigation systems that enable the printer to map out a room and execute precise printing tasks. By utilizing sensors and cameras, these devices can detect obstacles and adjust their paths accordingly, ensuring that the printing process is both efficient and accurate. This level of precision is crucial for creating detailed patterns and designs that were previously unattainable with traditional methods.

Moreover, the integration of vacuum technology into these mobile 3D printers serves a dual purpose. Not only does it allow the device to clean the surface before printing, ensuring optimal adhesion of the printed material, but it also enables the printer to function as a regular vacuum cleaner when not in use for printing. This multifunctionality adds a layer of practicality to the device, making it an attractive option for both residential and commercial spaces. As a result, users can enjoy the benefits of a clean environment while simultaneously enhancing the aesthetic appeal of their floors.

In addition to their practical applications, mobile 3D printers with vacuum capabilities offer significant environmental advantages. Traditional flooring methods often involve the use of materials that can be harmful to the environment, such as adhesives and synthetic compounds. In contrast, 3D printing technology allows for the use of eco-friendly materials, reducing the carbon footprint associated with floor design. Furthermore, the precision of 3D printing minimizes waste, as only the necessary amount of material is used to create the desired design. This sustainable approach aligns with the growing demand for environmentally conscious solutions in interior design.

The potential applications of this technology are vast and varied. In residential settings, homeowners can personalize their living spaces with unique floor designs that reflect their individual tastes and preferences. In commercial environments, businesses can utilize custom floor designs to enhance brand identity and create memorable experiences for customers. Additionally, the ability to easily update and modify floor designs offers a level of flexibility that is particularly appealing in dynamic spaces such as retail stores and exhibition halls.

As we look to the future, the continued development of mobile 3D printers with vacuum robot technology promises to unlock even more possibilities in floor design. Advances in materials science and robotics are likely to lead to even greater precision and efficiency, further expanding the creative potential of this technology. Ultimately, the integration of 3D printing and vacuum robot capabilities represents a significant step forward in the evolution of interior design, offering a harmonious blend of form and function that is both innovative and practical. As this technology becomes more accessible, it is set to transform the way we think about and interact with the spaces we inhabit.

The Future of Interior Design: Mobile 3D Printers and Vacuum Robots Unite

In the ever-evolving landscape of technology, the fusion of mobile 3D printing and vacuum robotics is poised to revolutionize the field of interior design. This innovative combination not only enhances the functionality of traditional 3D printers but also introduces a novel approach to floor design and decoration. As the demand for personalized and efficient home solutions grows, the integration of these technologies offers a glimpse into the future of interior spaces.

At the heart of this innovation is the mobile 3D printer, a device that has already transformed various industries by enabling on-site manufacturing and customization. Traditionally, 3D printers have been stationary, requiring objects to be designed and printed in a fixed location. However, the advent of mobile 3D printers allows for greater flexibility and adaptability, making it possible to create intricate designs directly on the surfaces of a home. This capability is particularly beneficial for interior designers who seek to offer bespoke solutions tailored to the unique preferences of their clients.

Simultaneously, vacuum robots have become a staple in modern households, known for their ability to autonomously clean floors with minimal human intervention. These devices have evolved significantly over the years, incorporating advanced sensors and navigation systems that enable them to traverse complex environments with ease. By combining the mobility and intelligence of vacuum robots with the creative potential of 3D printing, a new frontier in interior design emerges—one where floors can be transformed into canvases for artistic expression.

The integration of these technologies is not merely a theoretical concept but a practical solution that addresses several challenges faced by traditional interior design methods. For instance, the process of installing decorative flooring often involves labor-intensive procedures and significant material waste. Mobile 3D printers equipped with vacuum robot capabilities can mitigate these issues by precisely depositing materials only where needed, reducing waste and minimizing the environmental impact. Moreover, this approach allows for the creation of complex patterns and textures that would be difficult, if not impossible, to achieve through conventional means.

Furthermore, the union of mobile 3D printing and vacuum robotics opens up new possibilities for customization and personalization. Homeowners can now envision floors that reflect their individual tastes and lifestyles, with designs that can be easily modified or updated as desired. This level of personalization extends beyond aesthetics, as the technology can also be used to incorporate functional elements such as tactile surfaces for improved safety or embedded sensors for smart home integration.

As with any technological advancement, the adoption of mobile 3D printers combined with vacuum robots in interior design is not without its challenges. Issues such as cost, accessibility, and the need for specialized training may initially hinder widespread implementation. However, as the technology matures and becomes more affordable, it is likely that these barriers will diminish, paving the way for broader acceptance and utilization.

In conclusion, the convergence of mobile 3D printing and vacuum robotics represents a significant leap forward in the realm of interior design. By offering a versatile and efficient means of creating personalized floor designs, this innovative technology has the potential to redefine how we think about and interact with our living spaces. As we look to the future, it is clear that the marriage of these two technologies will play a pivotal role in shaping the homes of tomorrow, providing endless opportunities for creativity and innovation.

Exploring the Benefits of Combining Mobile 3D Printing and Vacuum Robotics for Floor Art

The advent of technology has consistently pushed the boundaries of creativity and functionality, leading to innovations that merge seemingly disparate fields. One such groundbreaking development is the integration of mobile 3D printing technology with vacuum robotics, resulting in a device capable of creating intricate floor art. This innovative combination not only enhances the versatility of 3D printing but also introduces a novel approach to interior design and artistic expression. By exploring the benefits of this fusion, we can better understand its potential impact on various industries and everyday life.

To begin with, the integration of mobile 3D printing with vacuum robotics offers unparalleled flexibility in creating floor art. Traditional 3D printers are typically stationary, limiting their application to objects that can fit within their build volume. However, by incorporating mobility, this new device can traverse large surfaces, enabling the creation of expansive and continuous designs directly on the floor. This capability is particularly advantageous for artists and designers seeking to transform large spaces with intricate patterns or murals, as it eliminates the need for manual labor and reduces the time required to complete such projects.

Moreover, the combination of these technologies enhances precision and accuracy in floor art creation. Vacuum robots are equipped with advanced sensors and navigation systems that allow them to map and navigate complex environments with ease. When paired with a 3D printing mechanism, these robots can execute detailed designs with a high degree of accuracy, ensuring that each element of the artwork is rendered precisely as intended. This level of precision is crucial for applications where intricate details are paramount, such as in the creation of logos, branding elements, or decorative motifs in commercial spaces.

In addition to precision, the use of mobile 3D printers with vacuum capabilities offers significant cost savings. Traditional methods of creating floor art, such as hand-painting or using stencils, can be labor-intensive and require skilled artisans, leading to higher costs. In contrast, this innovative device automates the process, reducing the need for manual intervention and thereby lowering labor expenses. Furthermore, the efficiency of the technology minimizes material waste, as the 3D printer can be programmed to use only the necessary amount of material for each design, contributing to overall cost-effectiveness.

Another notable benefit is the potential for customization and personalization. With the ability to easily program and modify designs, users can create bespoke floor art tailored to specific preferences or themes. This feature is particularly appealing in residential settings, where homeowners may wish to incorporate unique designs that reflect their personal style. Similarly, businesses can leverage this technology to create customized branding elements or thematic decorations that enhance their corporate identity and customer experience.

Finally, the environmental impact of this technology should not be overlooked. By optimizing material usage and reducing waste, mobile 3D printers with vacuum capabilities contribute to more sustainable practices in art and design. Additionally, the ability to use eco-friendly materials in the printing process further aligns with growing environmental consciousness and the demand for sustainable solutions.

In conclusion, the innovative combination of mobile 3D printing and vacuum robotics for floor art presents a multitude of benefits, ranging from enhanced flexibility and precision to cost savings and customization. As this technology continues to evolve, it holds the promise of transforming the way we approach interior design and artistic expression, offering new possibilities for creativity and efficiency in various settings.

Innovative Applications of Mobile 3D Printers with Vacuum Robots in Home Renovation

In recent years, the integration of advanced technologies has revolutionized various aspects of home renovation, offering innovative solutions that enhance efficiency and creativity. One such groundbreaking development is the combination of mobile 3D printers with vacuum robots, a fusion that has opened new avenues for floor printing capabilities. This innovative application not only streamlines the renovation process but also introduces a level of precision and customization previously unattainable with traditional methods.

The concept of mobile 3D printing is not entirely new; however, its amalgamation with vacuum robot technology marks a significant leap forward. By leveraging the mobility and autonomous navigation capabilities of vacuum robots, these hybrid devices can traverse a room with ease, laying down intricate designs and patterns directly onto the floor surface. This capability is particularly beneficial for creating bespoke flooring solutions, allowing homeowners to personalize their spaces with unique designs that reflect their individual tastes and preferences.

Moreover, the integration of 3D printing technology with vacuum robots enhances the precision and accuracy of floor printing. Traditional methods of floor design often involve labor-intensive processes that are prone to human error. In contrast, mobile 3D printers equipped with advanced sensors and mapping technologies can meticulously follow pre-programmed designs, ensuring that every detail is executed with exactitude. This level of precision not only improves the aesthetic quality of the finished product but also reduces material waste, making the process more sustainable and cost-effective.

In addition to precision, the versatility of this technology is another compelling advantage. Mobile 3D printers with vacuum capabilities can work with a variety of materials, including concrete, resin, and even certain types of wood composites. This flexibility allows for a wide range of applications, from creating durable industrial floors to crafting intricate decorative patterns in residential settings. Furthermore, the ability to switch between different materials seamlessly enables homeowners and designers to experiment with mixed-media designs, adding depth and texture to their flooring projects.

The user-friendly nature of these devices also contributes to their growing popularity in the home renovation sector. With intuitive interfaces and easy-to-use software, even those with limited technical expertise can operate these machines effectively. Homeowners can simply select or design their desired floor pattern using a computer or mobile app, and the device will autonomously execute the task. This democratization of technology empowers individuals to take a more active role in their home renovation projects, fostering creativity and innovation.

Despite the numerous advantages, it is important to acknowledge the challenges associated with this emerging technology. The initial cost of acquiring a mobile 3D printer with vacuum capabilities can be prohibitive for some homeowners. Additionally, as with any new technology, there is a learning curve involved in mastering its use. However, as the technology continues to evolve and become more accessible, it is likely that these barriers will diminish over time.

In conclusion, the innovative application of mobile 3D printers combined with vacuum robots represents a significant advancement in the field of home renovation. By offering unparalleled precision, versatility, and user-friendliness, this technology has the potential to transform the way we approach floor design and customization. As it becomes more widely adopted, it promises to not only enhance the aesthetic appeal of our living spaces but also contribute to more sustainable and efficient renovation practices.

Enhancing Creativity: The Role of Mobile 3D Printers and Vacuum Robots in Custom Flooring

In recent years, the intersection of technology and creativity has led to remarkable innovations, one of which is the development of a mobile 3D printer that integrates the functionality of a vacuum robot to offer custom flooring solutions. This groundbreaking device not only redefines the possibilities of interior design but also enhances the efficiency and precision of creating intricate floor patterns. As the demand for personalized and unique home and office spaces grows, this innovative technology stands at the forefront of transforming how we approach flooring design.

The concept of combining a 3D printer with a vacuum robot may initially seem unconventional, yet it is precisely this fusion that enables the creation of complex and detailed floor designs. Traditional flooring methods often involve labor-intensive processes and limited design options. However, the mobile 3D printer with vacuum capabilities revolutionizes this by allowing for the seamless printing of intricate patterns directly onto the floor surface. This is achieved through advanced software that guides the printer to deposit materials in precise layers, creating a three-dimensional effect that is both visually stunning and structurally sound.

Moreover, the integration of vacuum technology plays a crucial role in ensuring the accuracy and cleanliness of the printing process. As the printer moves across the floor, the vacuum component effectively removes dust and debris, which could otherwise interfere with the printing process. This not only enhances the quality of the final product but also reduces the need for extensive post-printing cleaning, making the entire process more efficient. Additionally, the vacuum feature allows the printer to adhere closely to the floor surface, ensuring that the printed design remains consistent and free from distortions.

Transitioning from traditional methods to this innovative approach also offers significant environmental benefits. The materials used in 3D printing are often more sustainable and can be tailored to include recycled components, reducing the overall carbon footprint of flooring projects. Furthermore, the precision of 3D printing minimizes material waste, as only the necessary amount of material is used to create the desired design. This contrasts sharply with conventional flooring methods, which often result in excess material that contributes to environmental degradation.

In addition to its environmental advantages, the mobile 3D printer with vacuum capabilities opens up new avenues for creativity and personalization in interior design. Homeowners and designers can now experiment with a wide range of colors, textures, and patterns that were previously difficult or impossible to achieve. This technology empowers individuals to create spaces that truly reflect their personal style and preferences, enhancing the aesthetic appeal and uniqueness of their environments.

As we look to the future, the potential applications of this technology extend beyond residential and commercial spaces. The ability to print custom designs on various surfaces could revolutionize industries such as hospitality, retail, and even art installations. By offering a versatile and efficient solution for creating bespoke floor designs, the mobile 3D printer with vacuum capabilities is poised to become an indispensable tool in the toolkit of designers and architects worldwide.

In conclusion, the innovative combination of a mobile 3D printer and vacuum robot represents a significant leap forward in the realm of custom flooring. By enhancing creativity, improving efficiency, and offering sustainable solutions, this technology not only meets the demands of modern design but also sets the stage for future advancements in the field. As it continues to evolve, it promises to redefine the boundaries of what is possible in interior design, paving the way for a new era of personalized and environmentally conscious spaces.

Q&A

1. **What is the Innovative Mobile 3D Printer?**

– It is a device that combines 3D printing technology with a vacuum robot to enable floor printing capabilities.

2. **How does the vacuum robot function in this device?**

– The vacuum robot component allows the printer to move autonomously across floors, positioning itself accurately for printing tasks.

3. **What are the potential applications of this technology?**

– Potential applications include creating intricate floor designs, signage, and custom decorations directly on surfaces like tiles or concrete.

4. **What are the benefits of combining a 3D printer with a vacuum robot?**

– This combination allows for greater mobility and flexibility in printing, enabling large-scale projects and reducing the need for manual repositioning.

5. **What challenges might this technology face?**

– Challenges could include ensuring precise alignment during movement, managing power consumption, and dealing with uneven surfaces.

6. **Who might be the target users for this technology?**

– Target users could include interior designers, event planners, construction companies, and artists looking for innovative ways to create floor designs.The innovative mobile 3D printer that combines vacuum robot technology for floor printing capabilities represents a significant advancement in additive manufacturing and robotics. By integrating the precision and automation of 3D printing with the mobility and versatility of a vacuum robot, this technology offers new possibilities for on-site, large-scale, and complex floor designs. It enhances efficiency by reducing the need for manual intervention and allows for intricate patterns and textures to be printed directly onto surfaces. This fusion of technologies could revolutionize industries such as construction, interior design, and custom manufacturing, providing a flexible and scalable solution for creating unique and functional floor designs.